產品介紹

1.槽溝加工研究 Master of Grooving

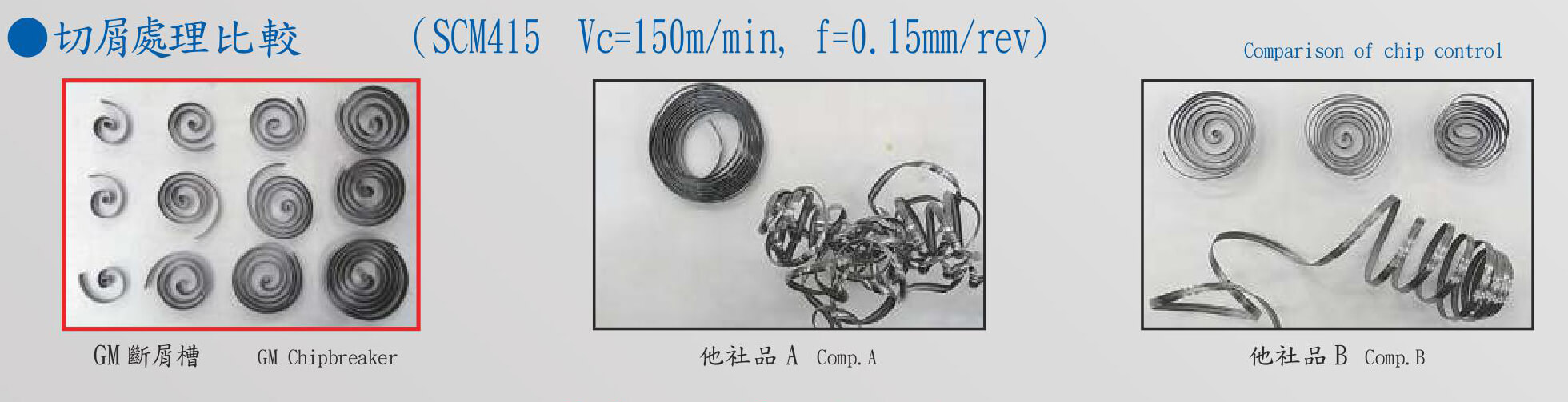

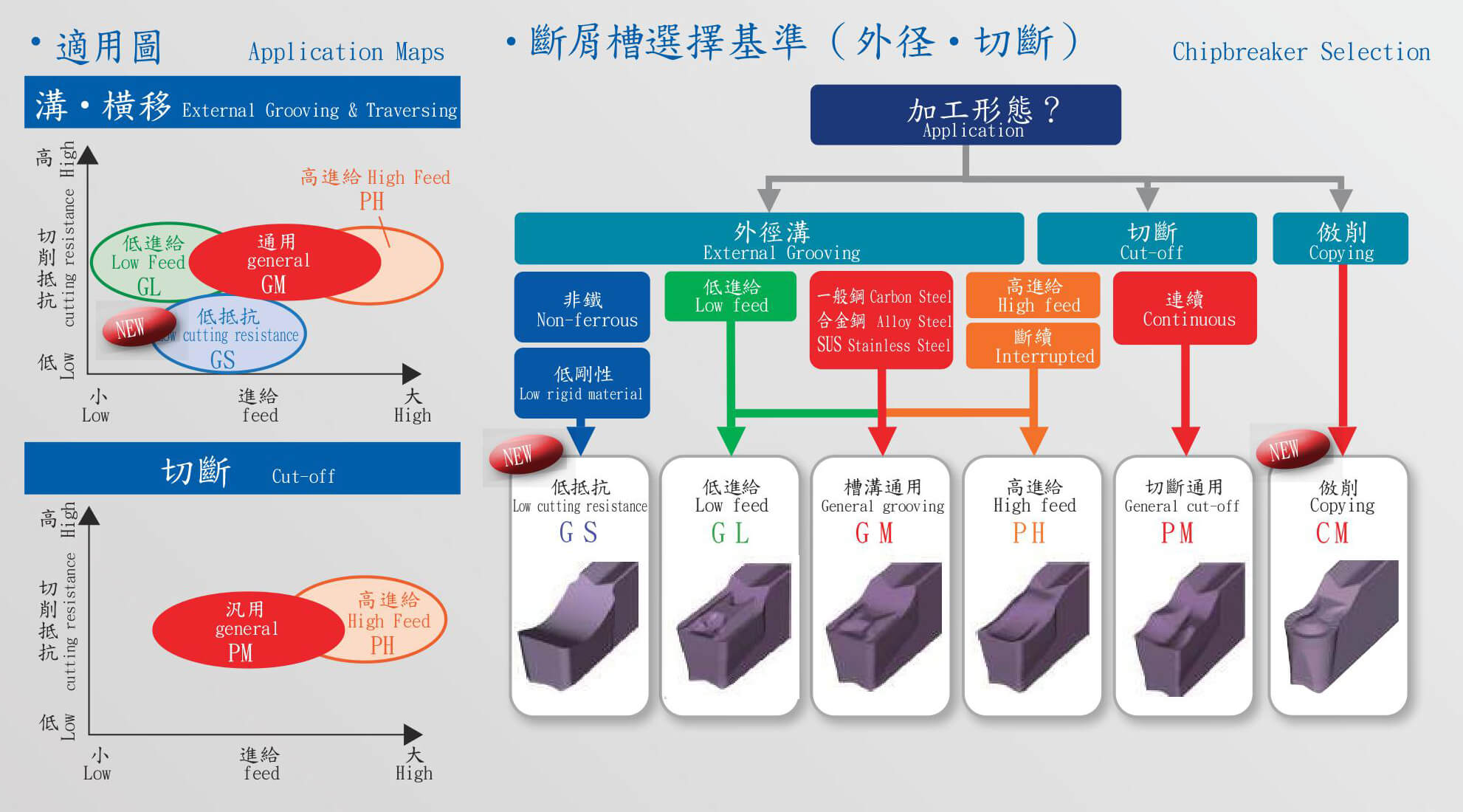

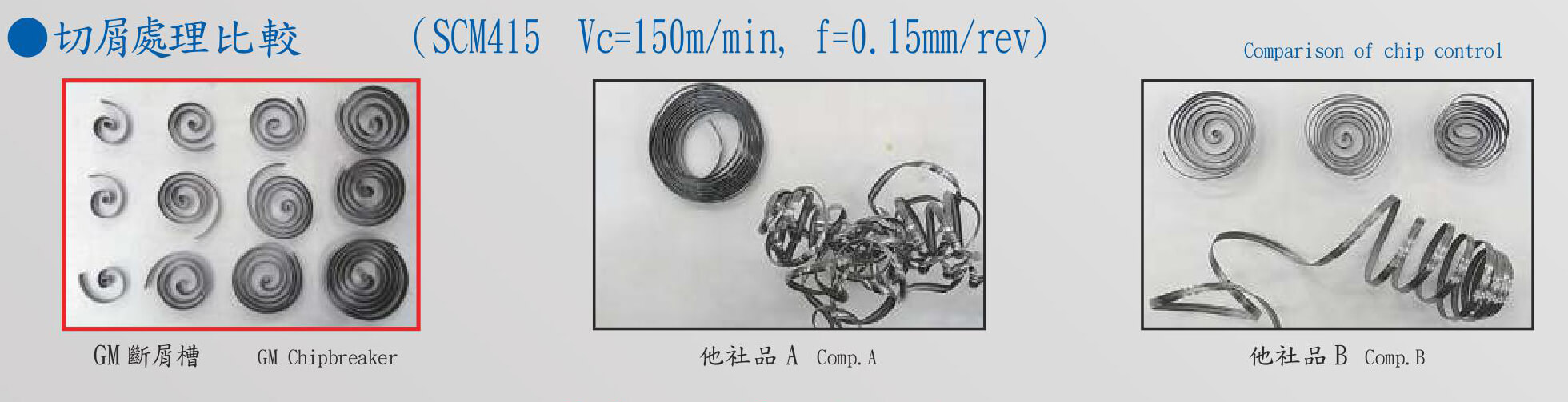

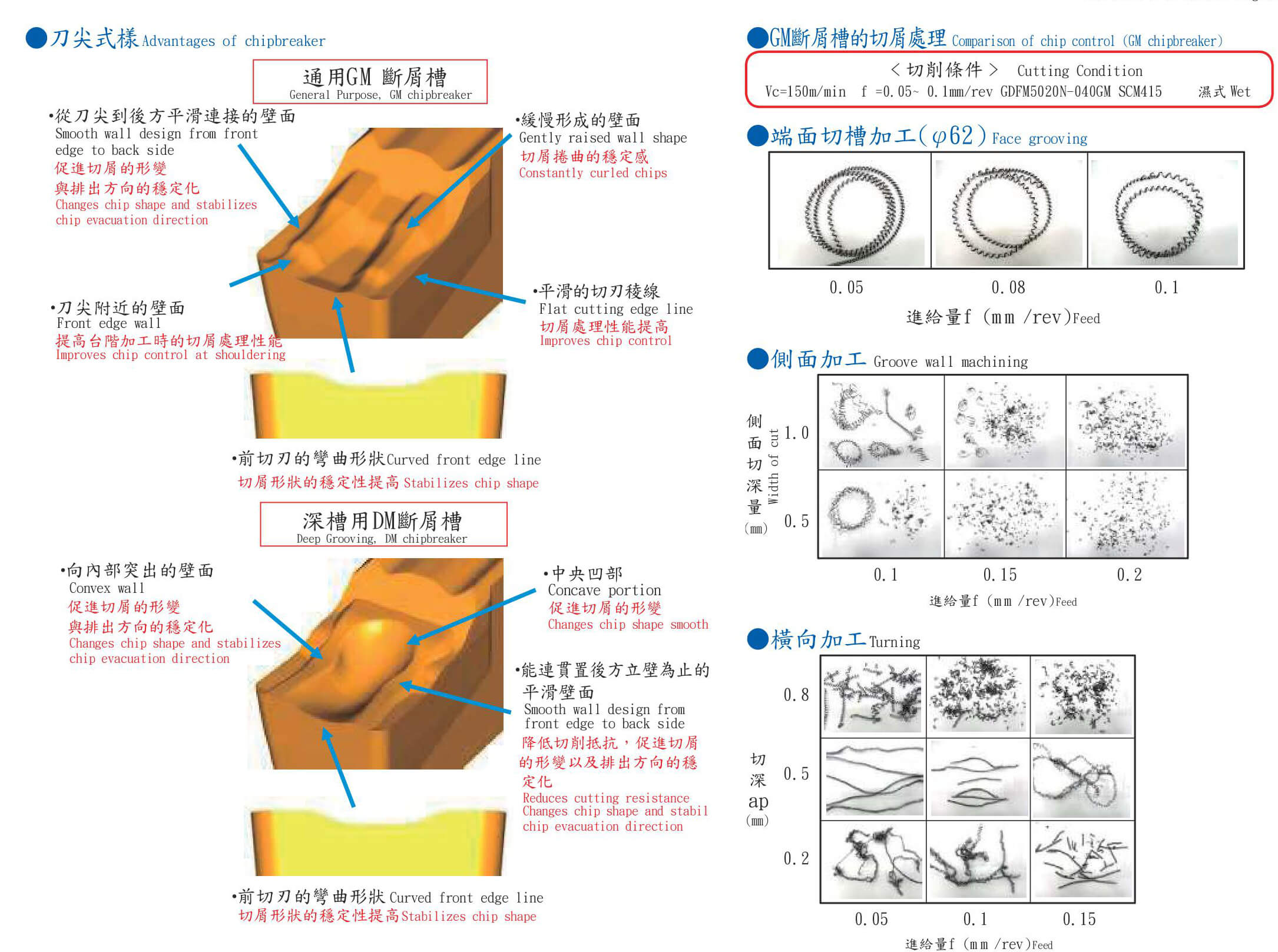

- 良好的切屑處理 Good chip control

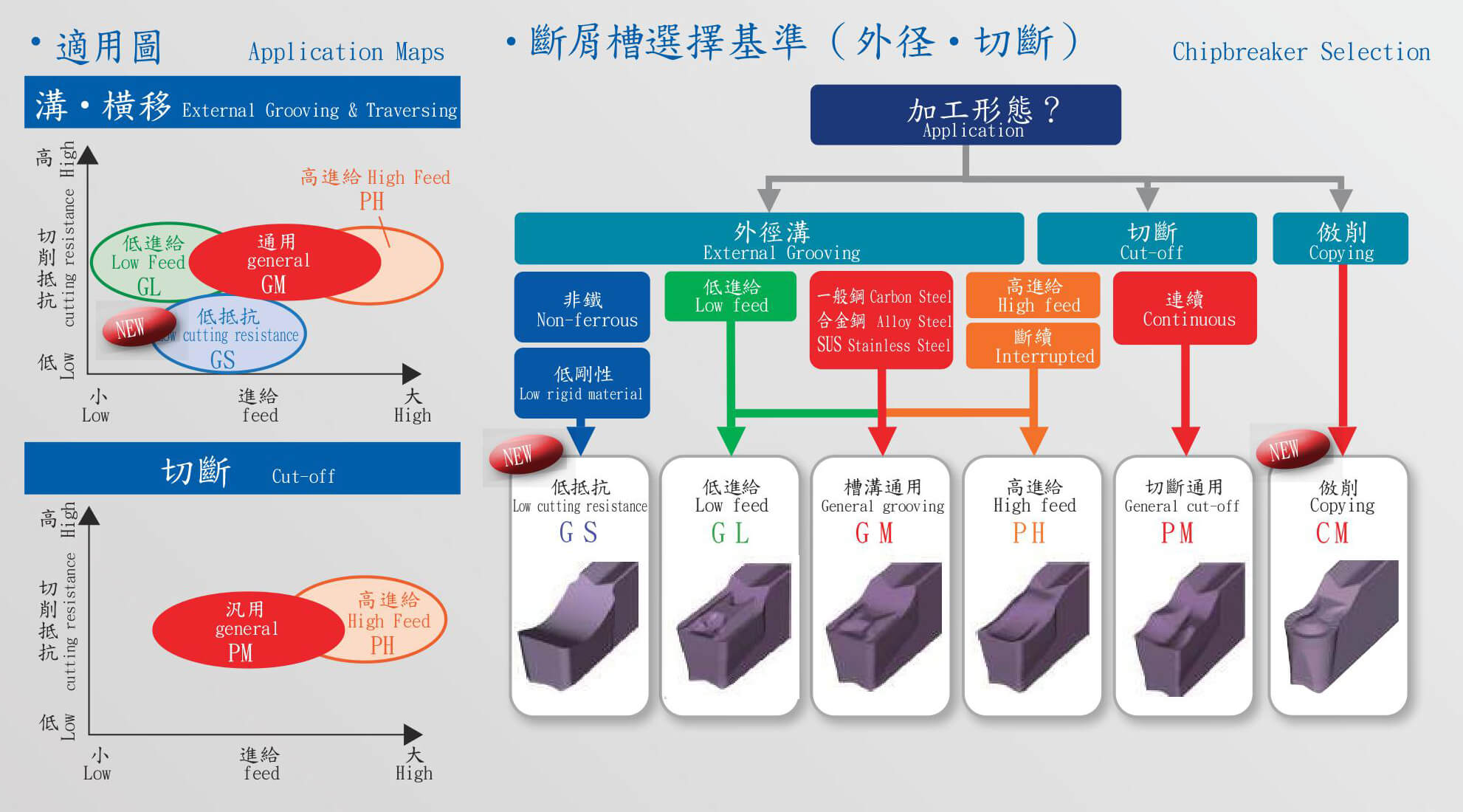

- 涵蓋多樣工件材種,新斷屑槽現已發行

Covers a variety of workpiece materials. New chipbreakers are now available

- 高精度之刃口 High precision edge prepeariation

- 高精度研磨技術刀幅公差±0.03mm(溝幅 2,3,4)

High precision molding technology tolerance ±0.03mm (Edge width 2, 3, 4mm type)

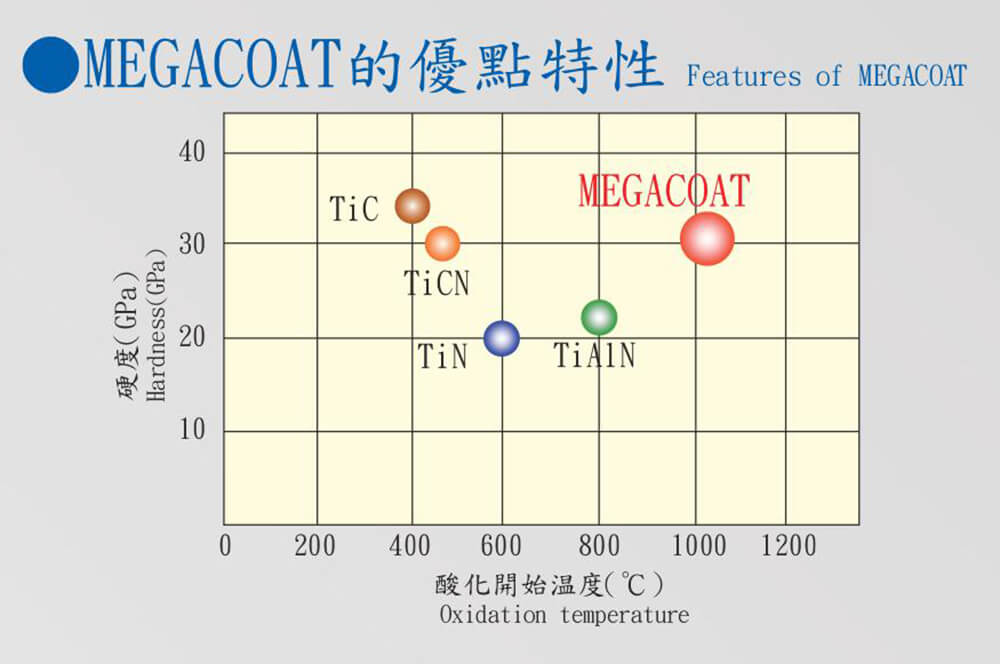

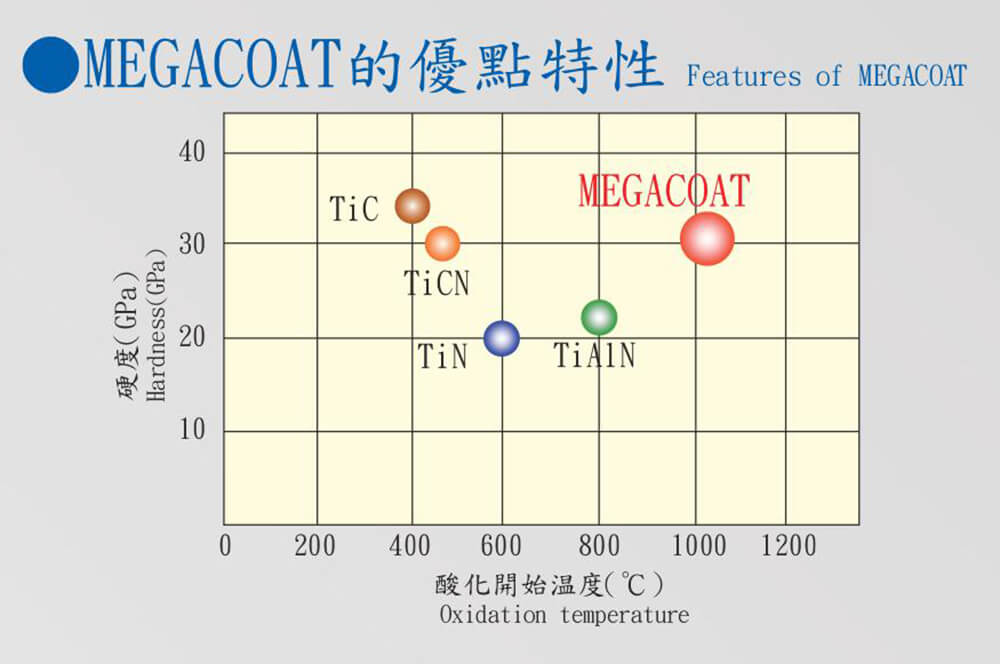

- 採用廣受好評的MEGACOAT

MEGACOAT technology

- 優秀的耐酸化性和耐摩耗性、實現長壽命和高效能之加工

Long tool life and high efficiency machining by high oxidation resistance and wear resistance.

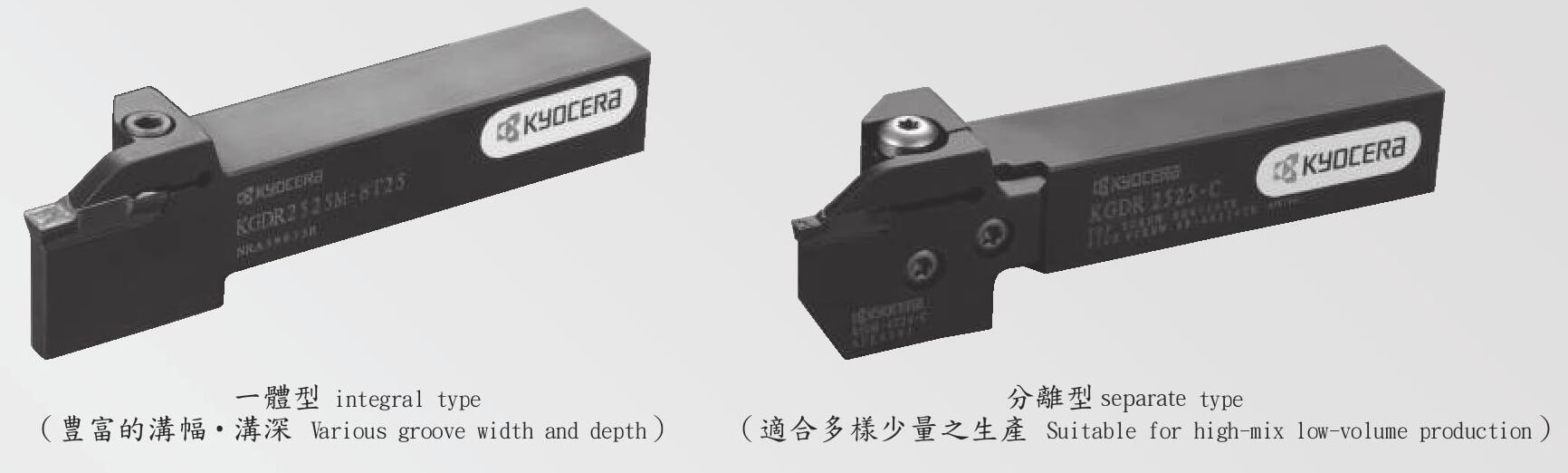

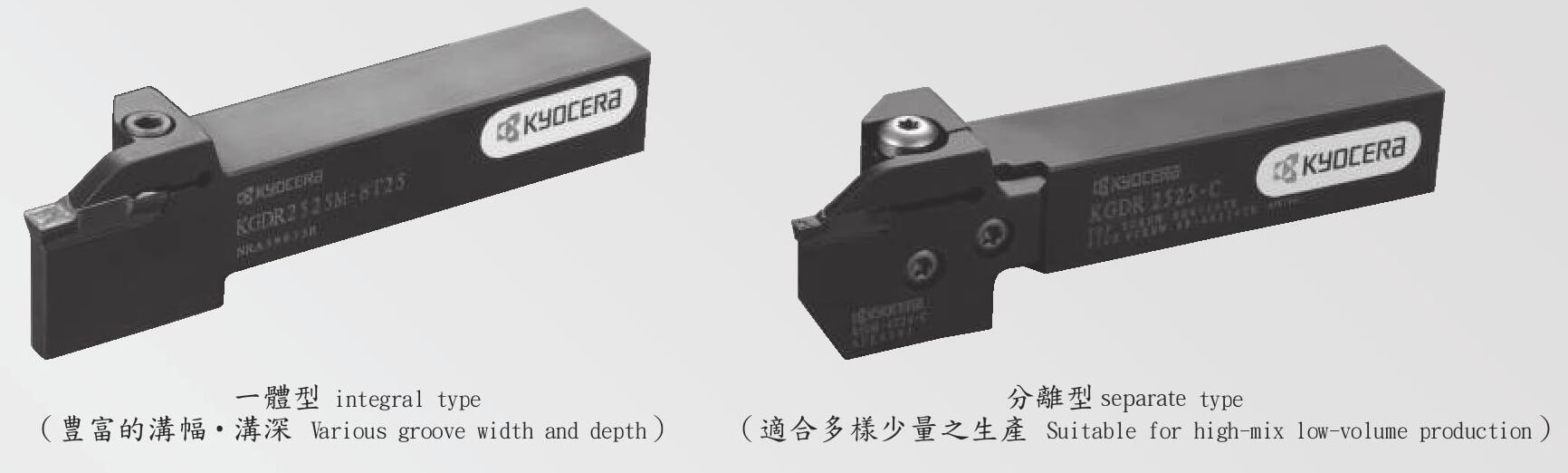

- 多樣化的刀桿選擇 Various Toolholder lineup

- 豐富的一體型刀桿、多品種少量生產最為適合的分離型刀桿。

Integral type toolholder with wide lineup and Separate type toolholder for high-mix low-volume production are available.

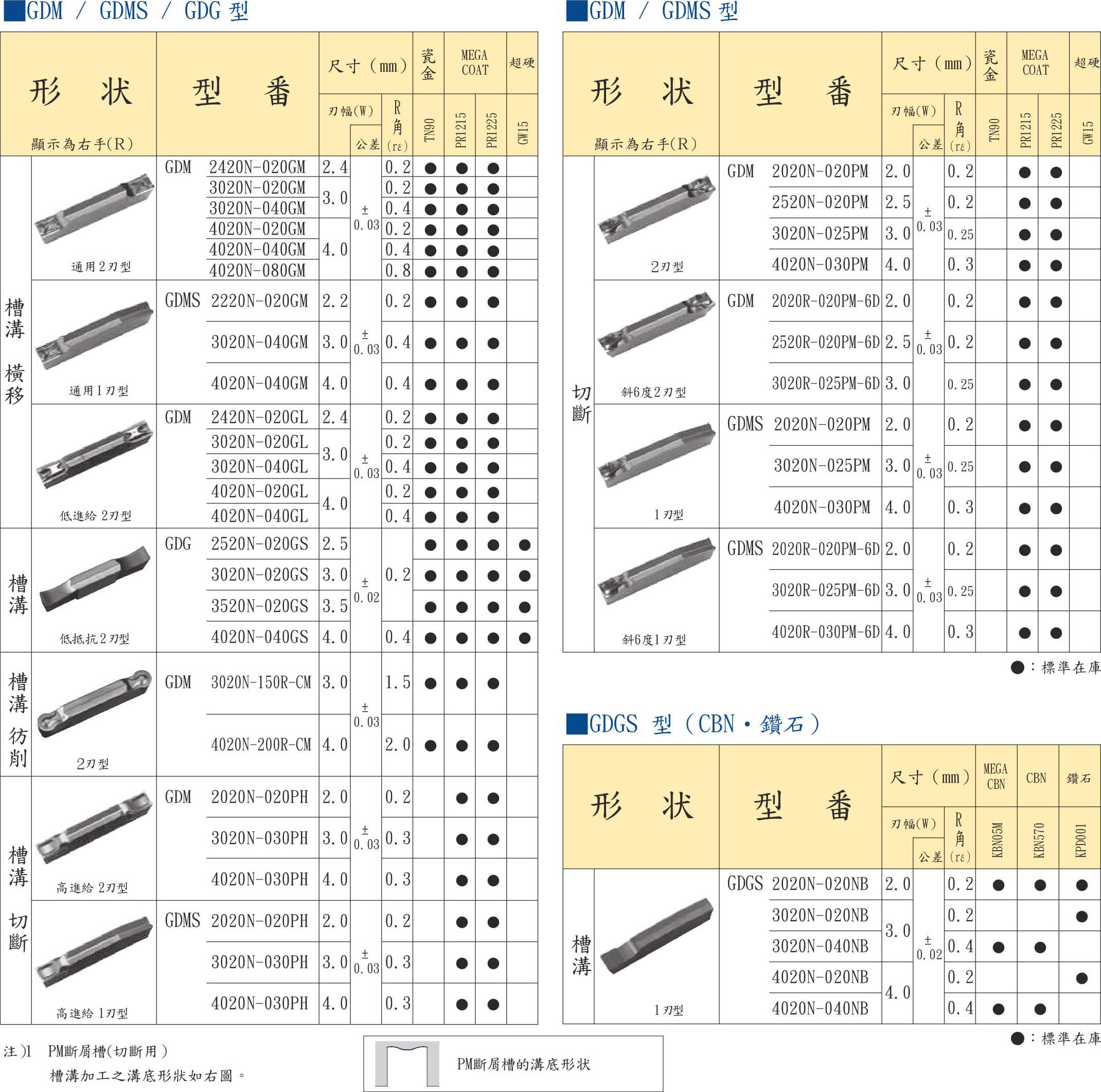

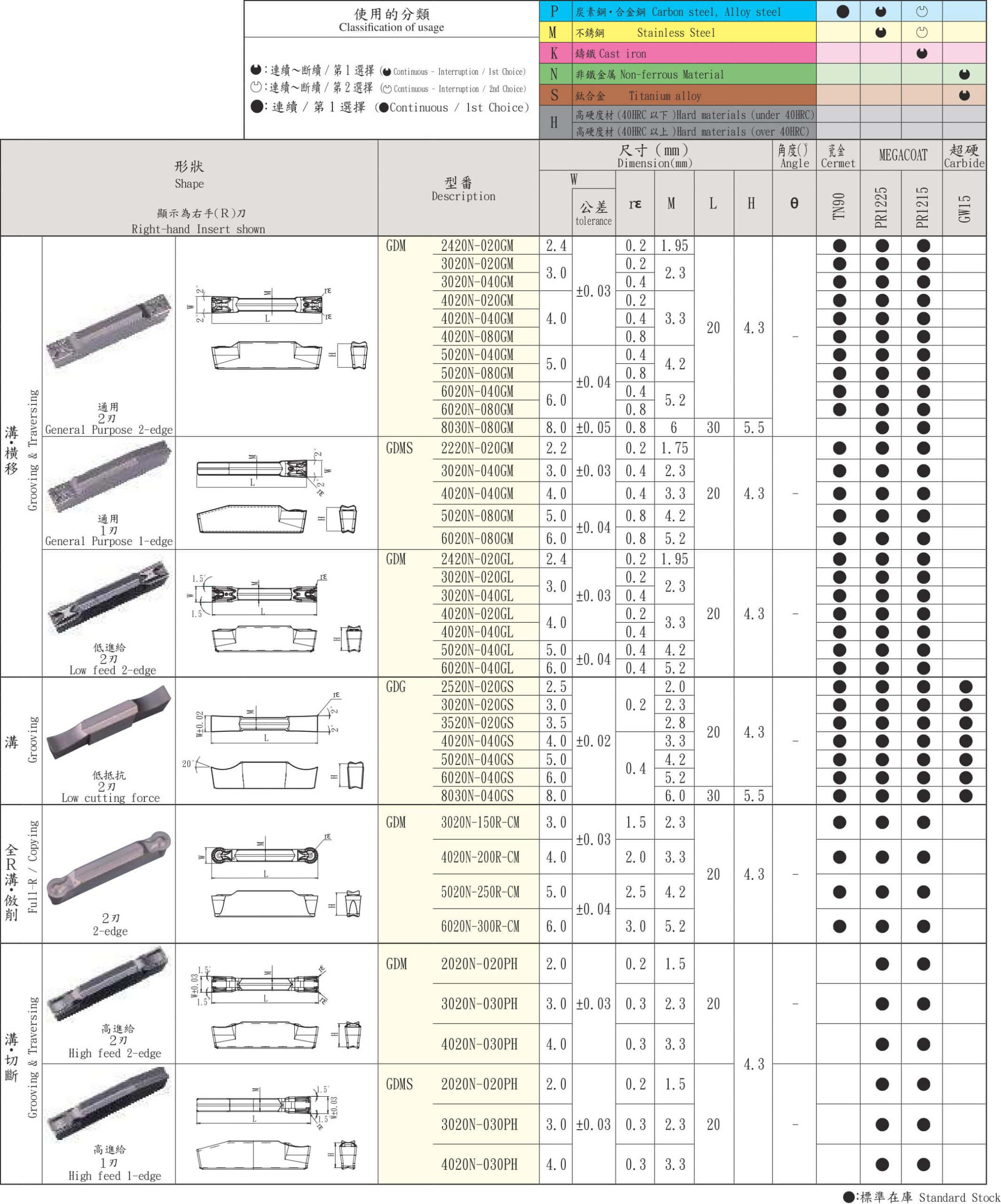

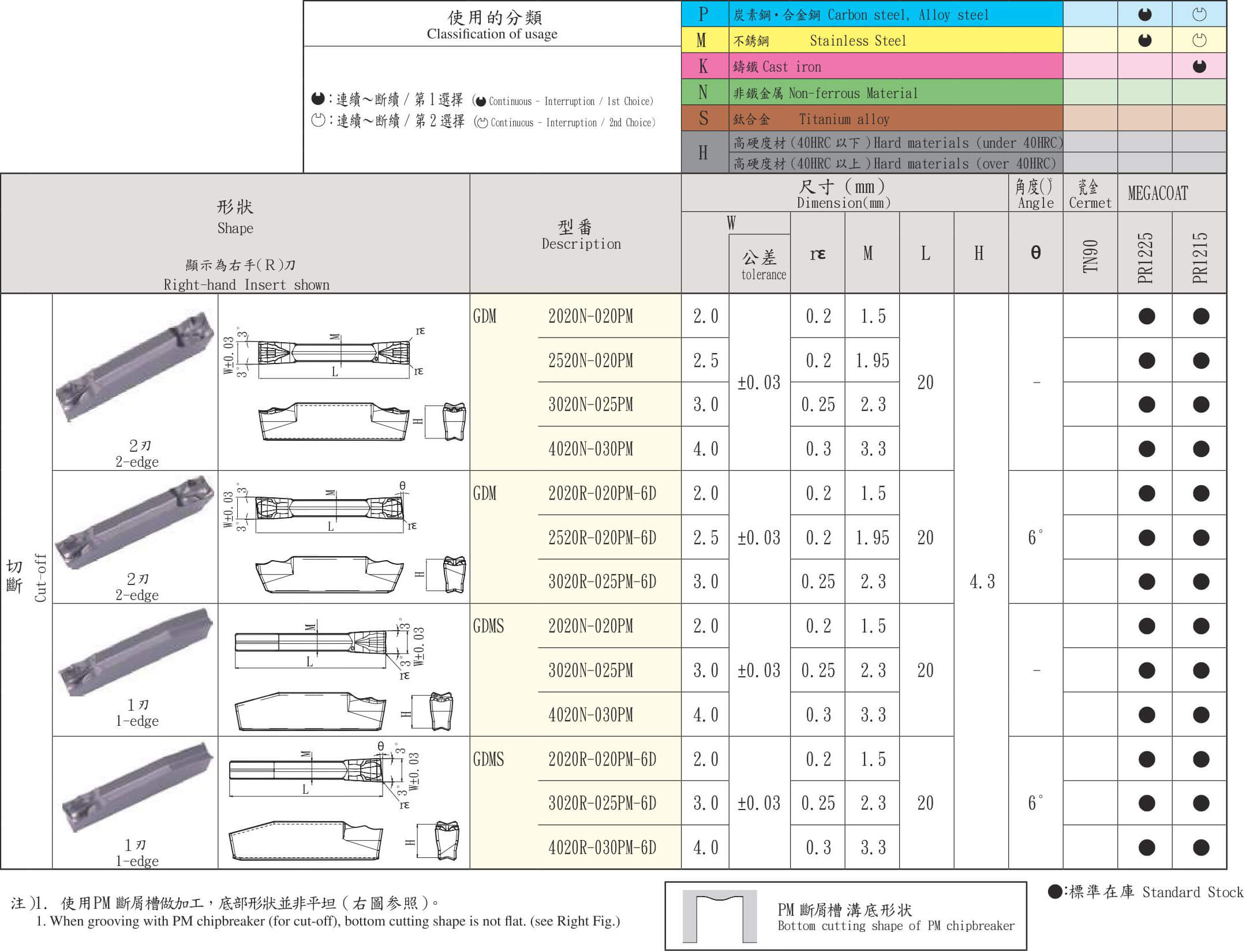

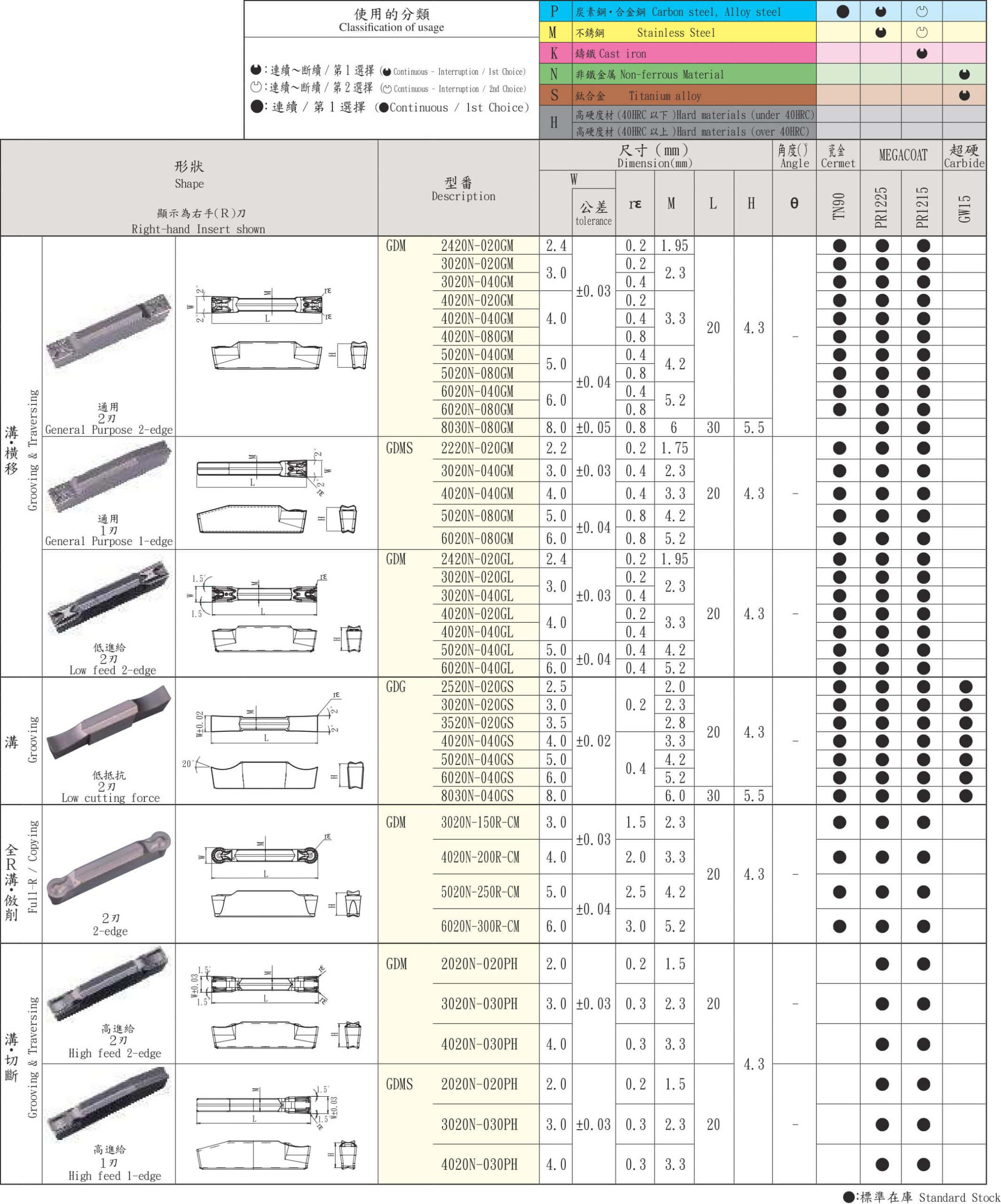

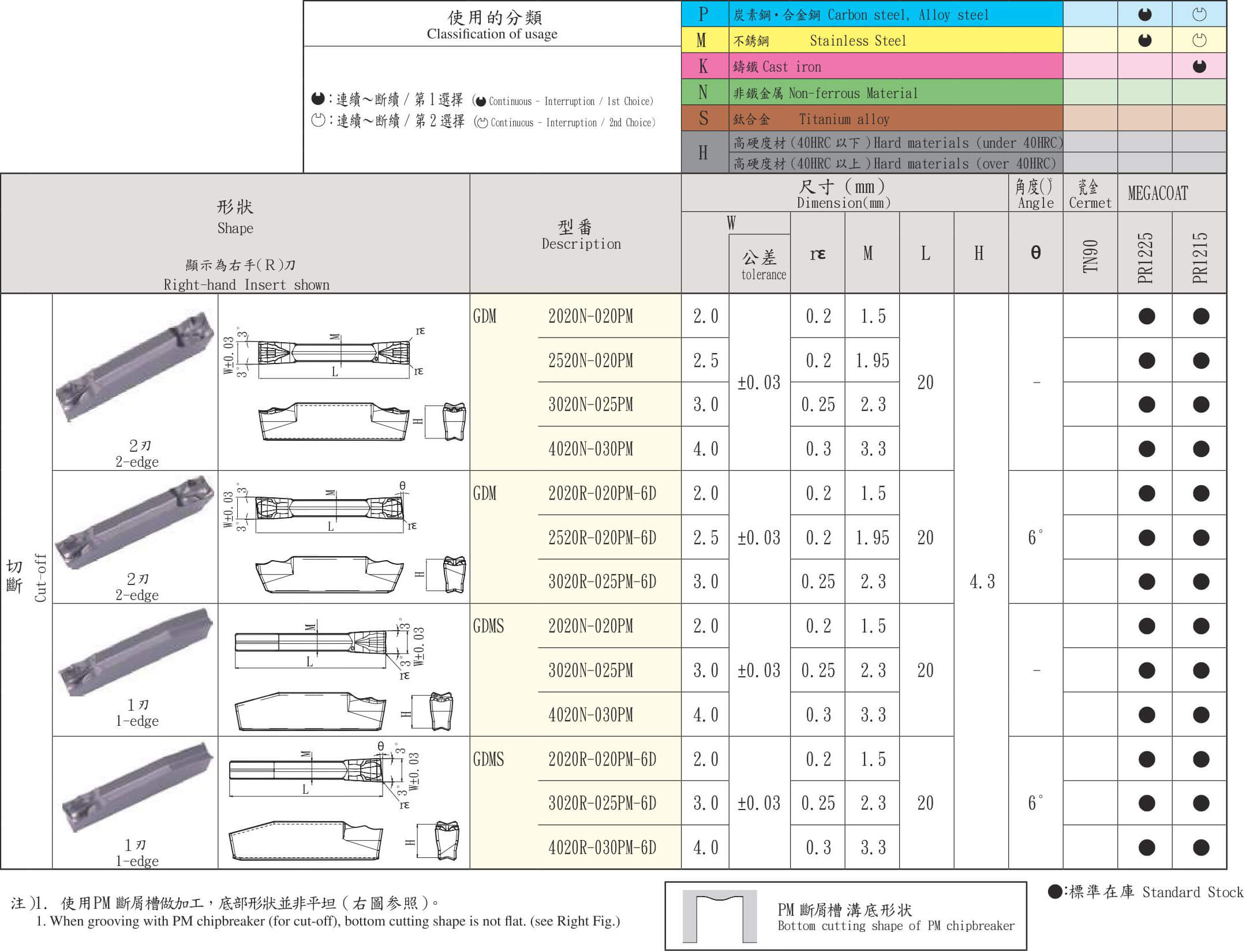

外徑溝·切斷用及橫移之刀片

Inserts lineup for External grooving, Traversing and Cut-off.

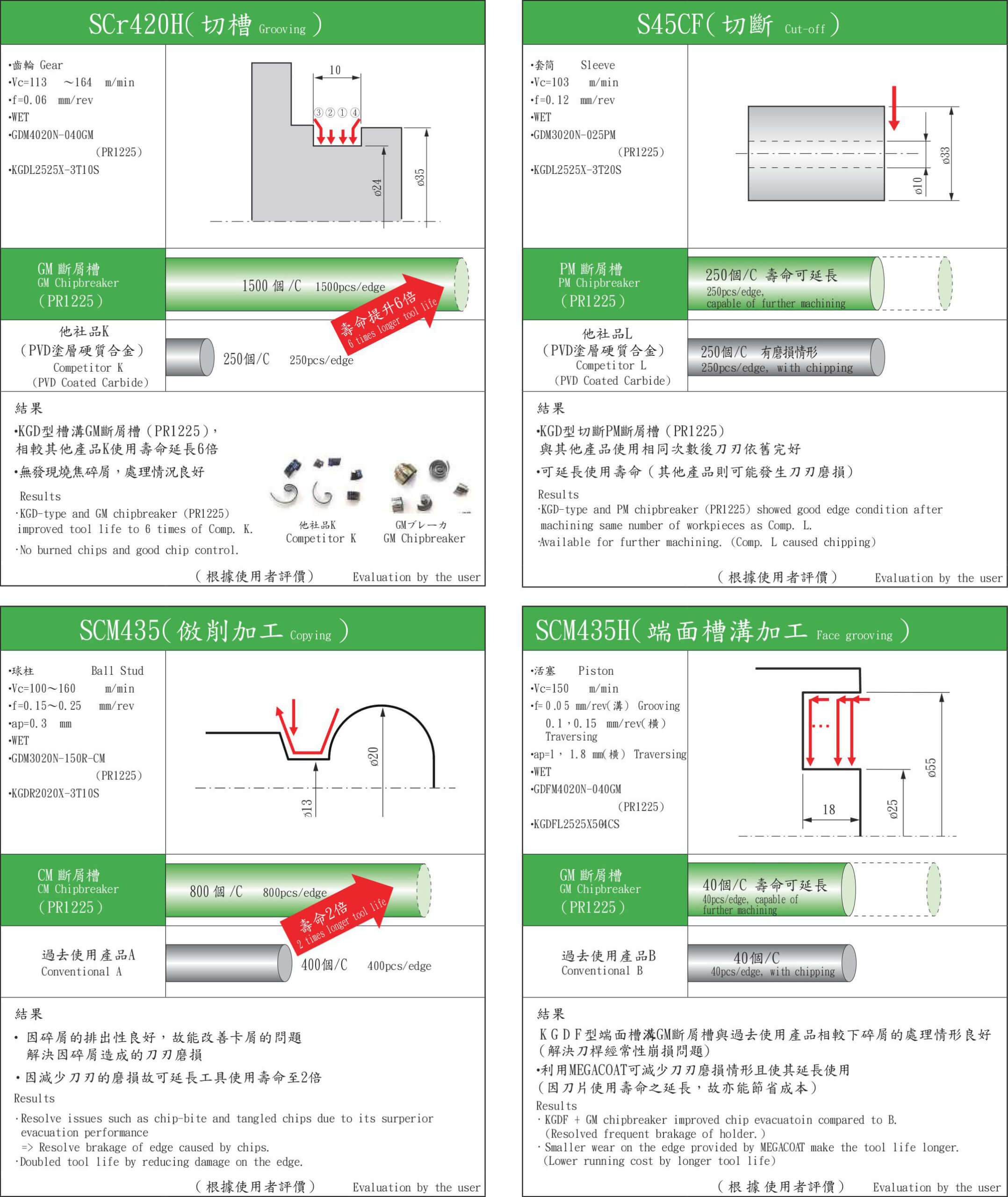

良好的切削處理,改善生產力

Good chip control to contribute productivity improvement

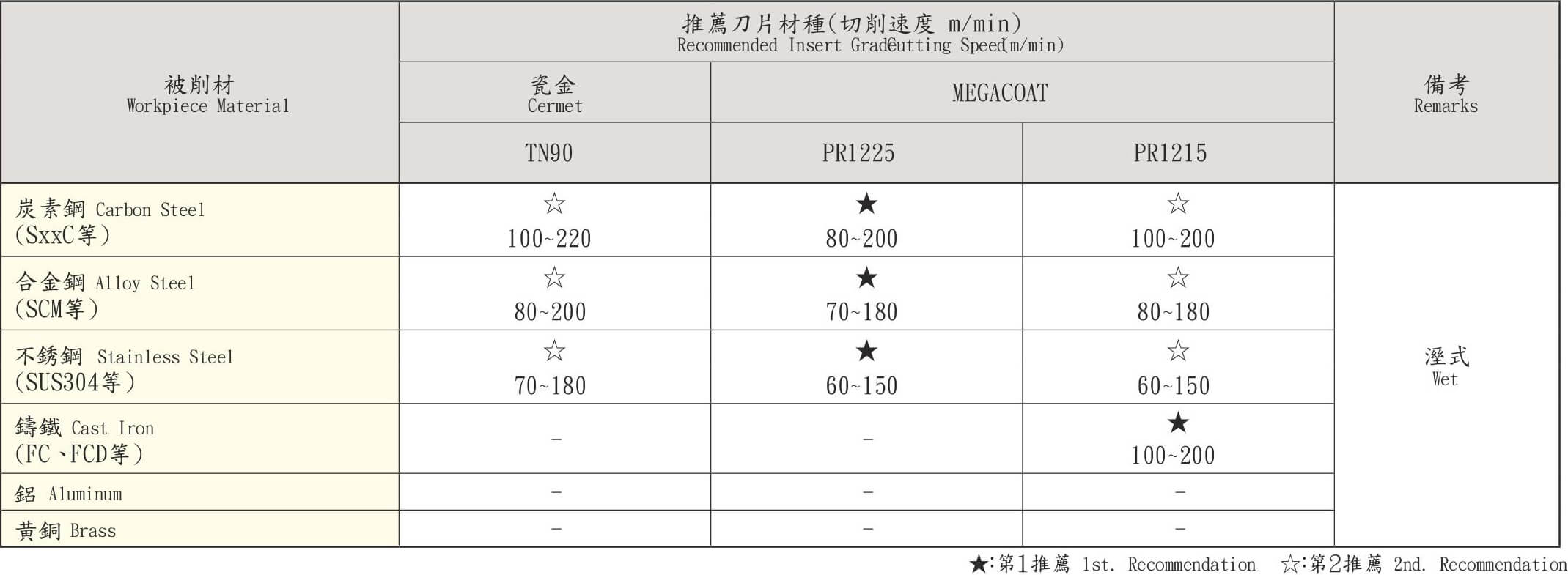

長壽命塗層 MEGACOAT

Long tool life coating “MEGACOAT

PR1225 :

切斷・槽溝·横移加工的第一推薦材種

PRI 225: Ist. Recommendation for cut-off , grooving and traversing

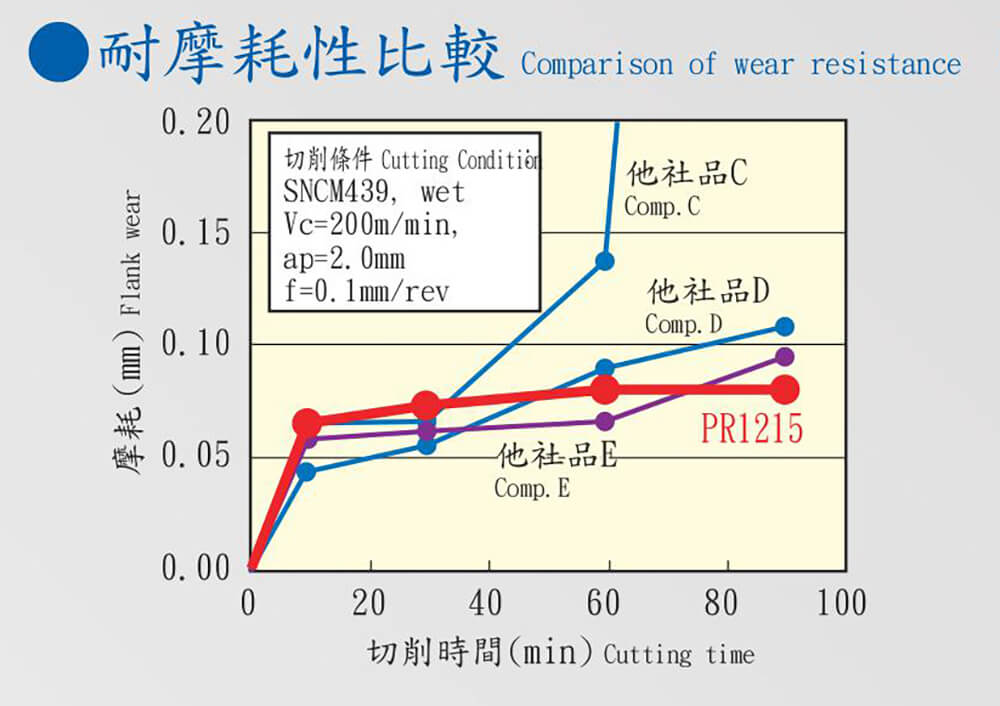

PR1215 :

耐摩耗性優良、安定條件下槽溝·切斷加工用鑄鐵加工推薦

PR1215: With superior wear resistance, recommended for grooving and cut-off under the stable conditions.

1st. Recommendation for machining of cast iron.

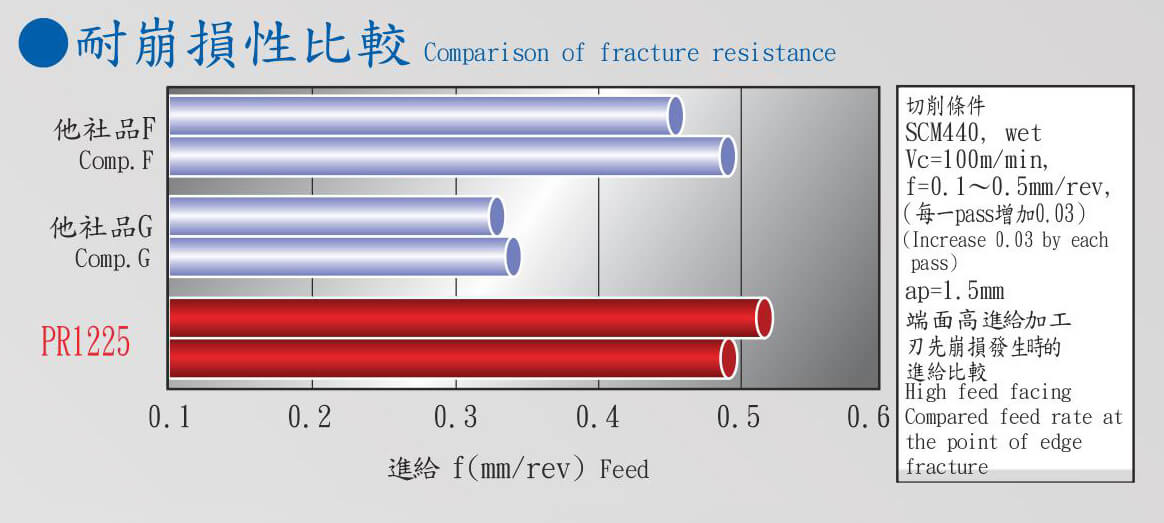

良好的耐磨耗性,耐崩損性

Good wear resistance and fracture resistance

穩定的槽溝 • 切斷加工、實現長壽命

Stable cutting and long tool life at grooving and cut-off

多樣化產品線

Various lineup

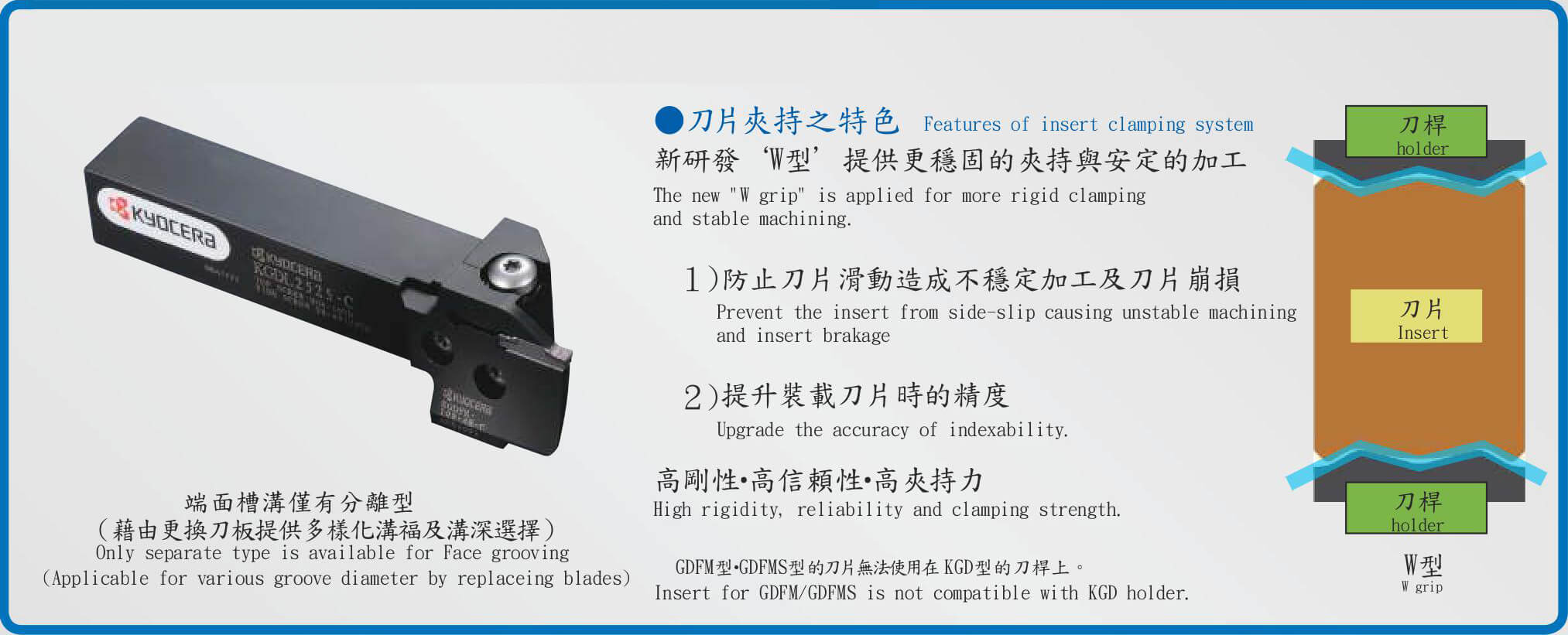

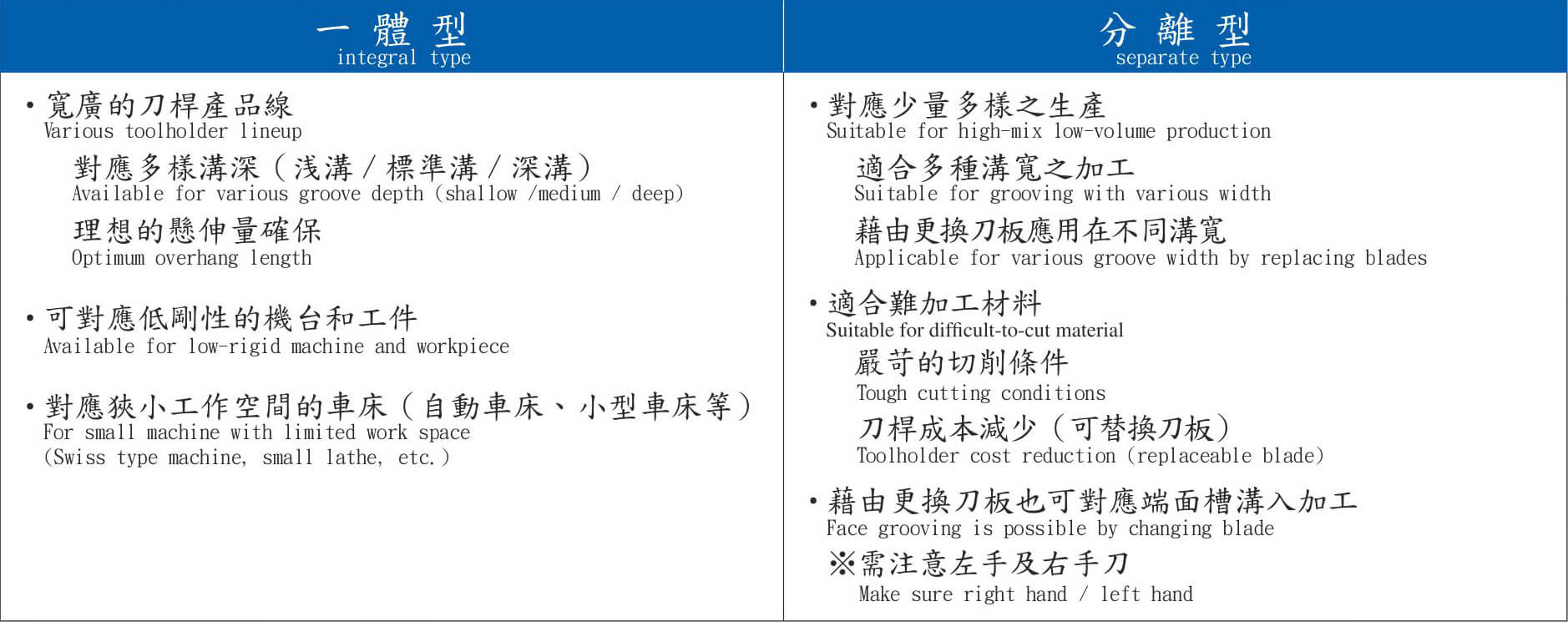

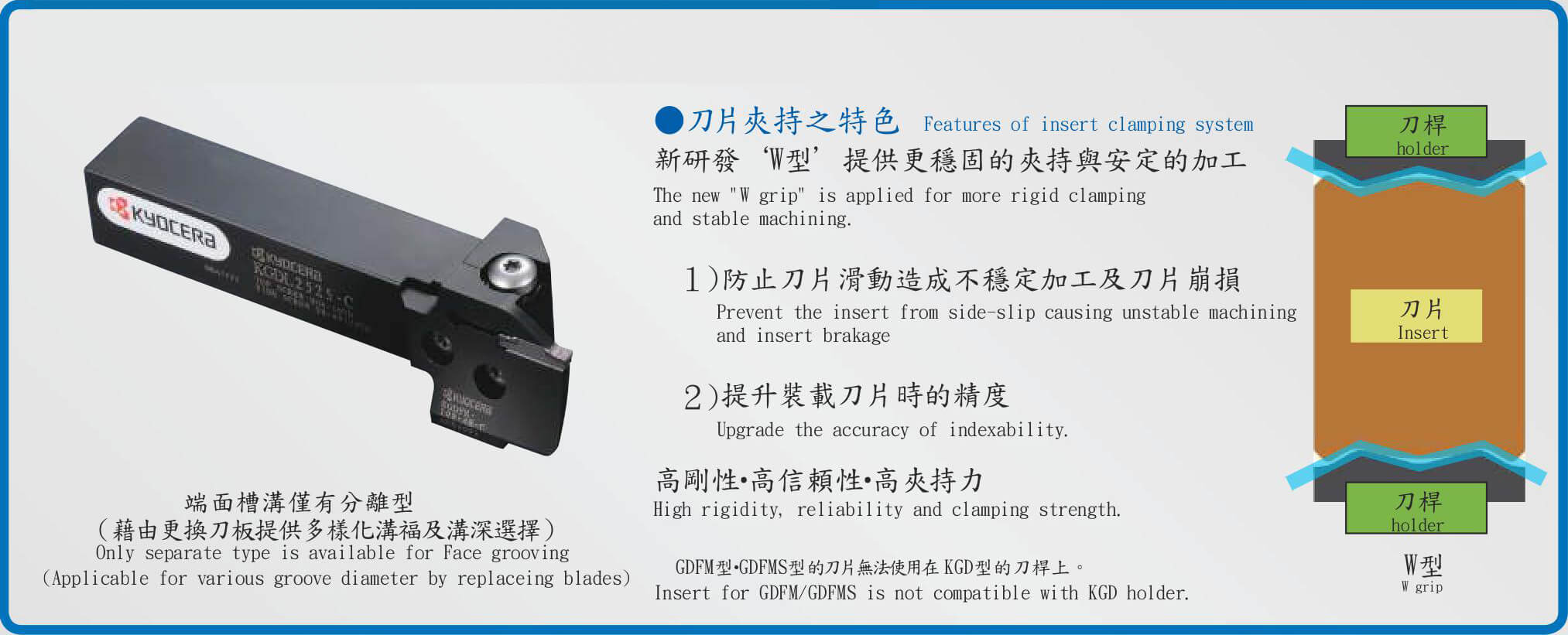

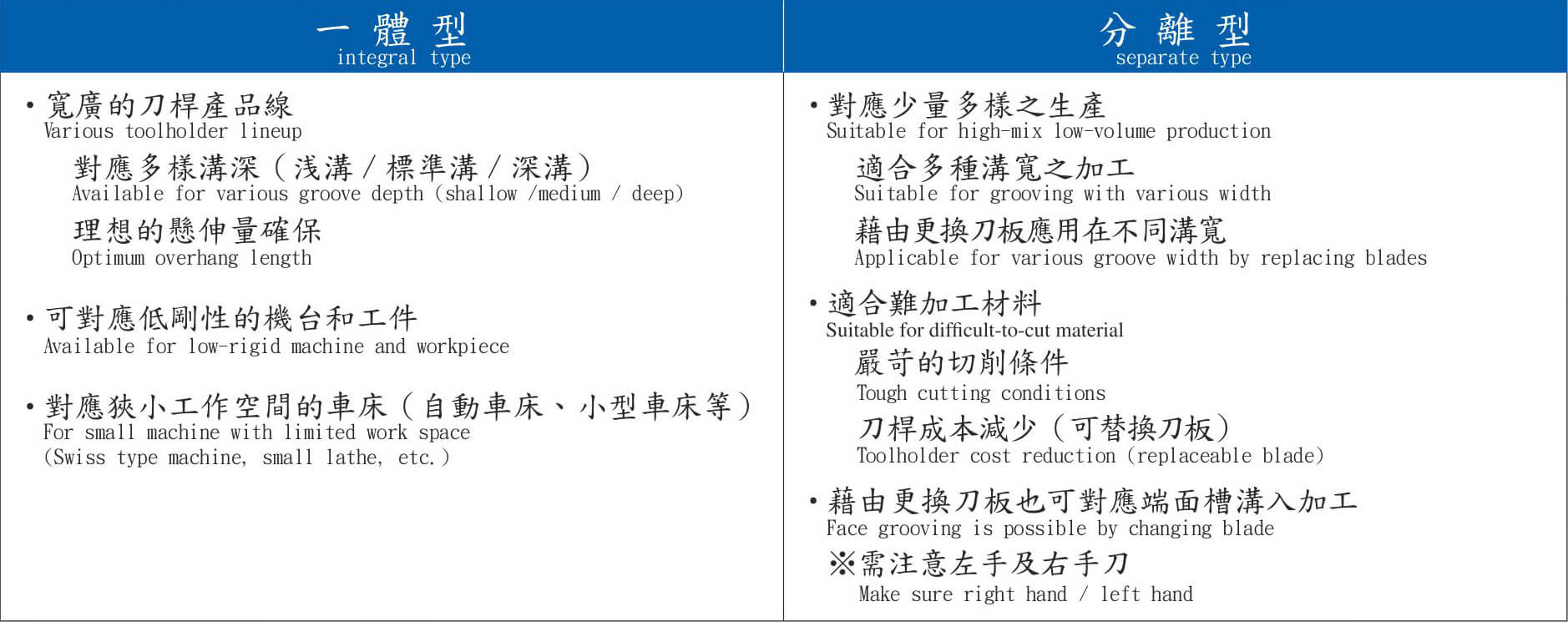

兩種類型支刀桿提供選擇:一體型與分離型(本體+刀板)

Available two types of toolholder, Integral type and Separate type,

端面槽溝 • 刀桿刀片

Toolholder and Inserts for Face grooving.

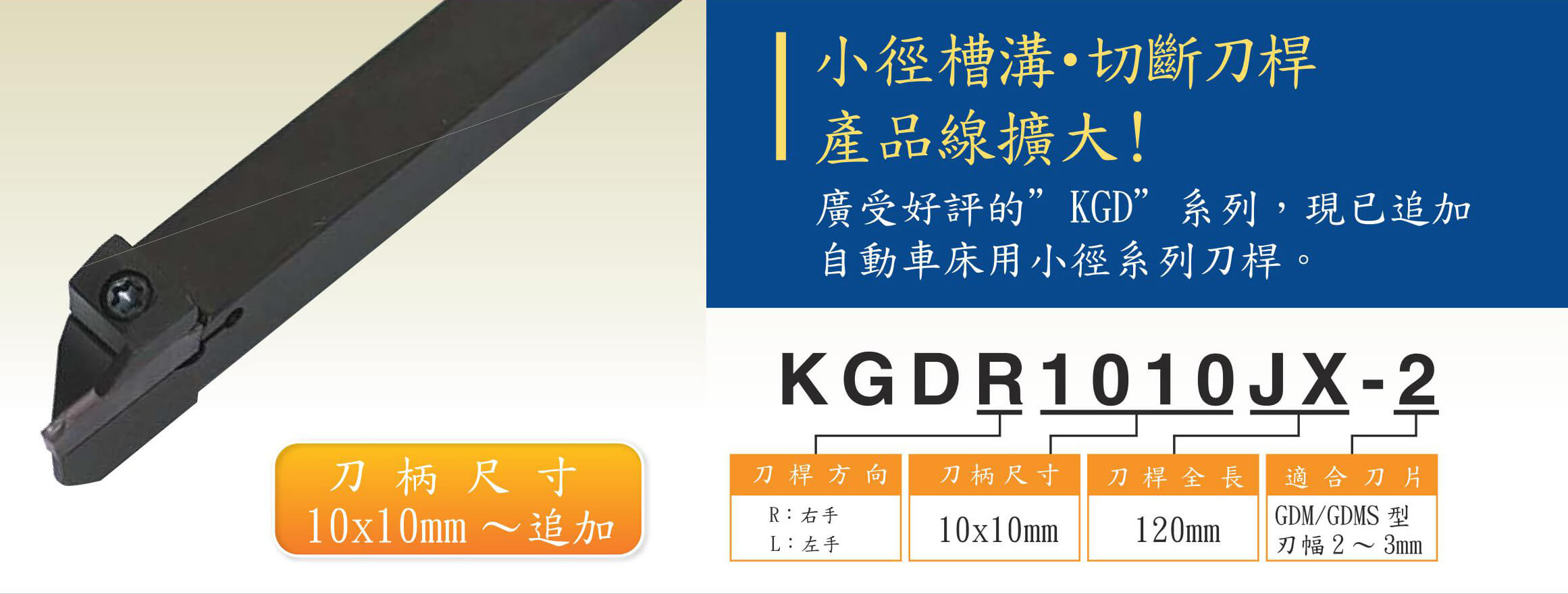

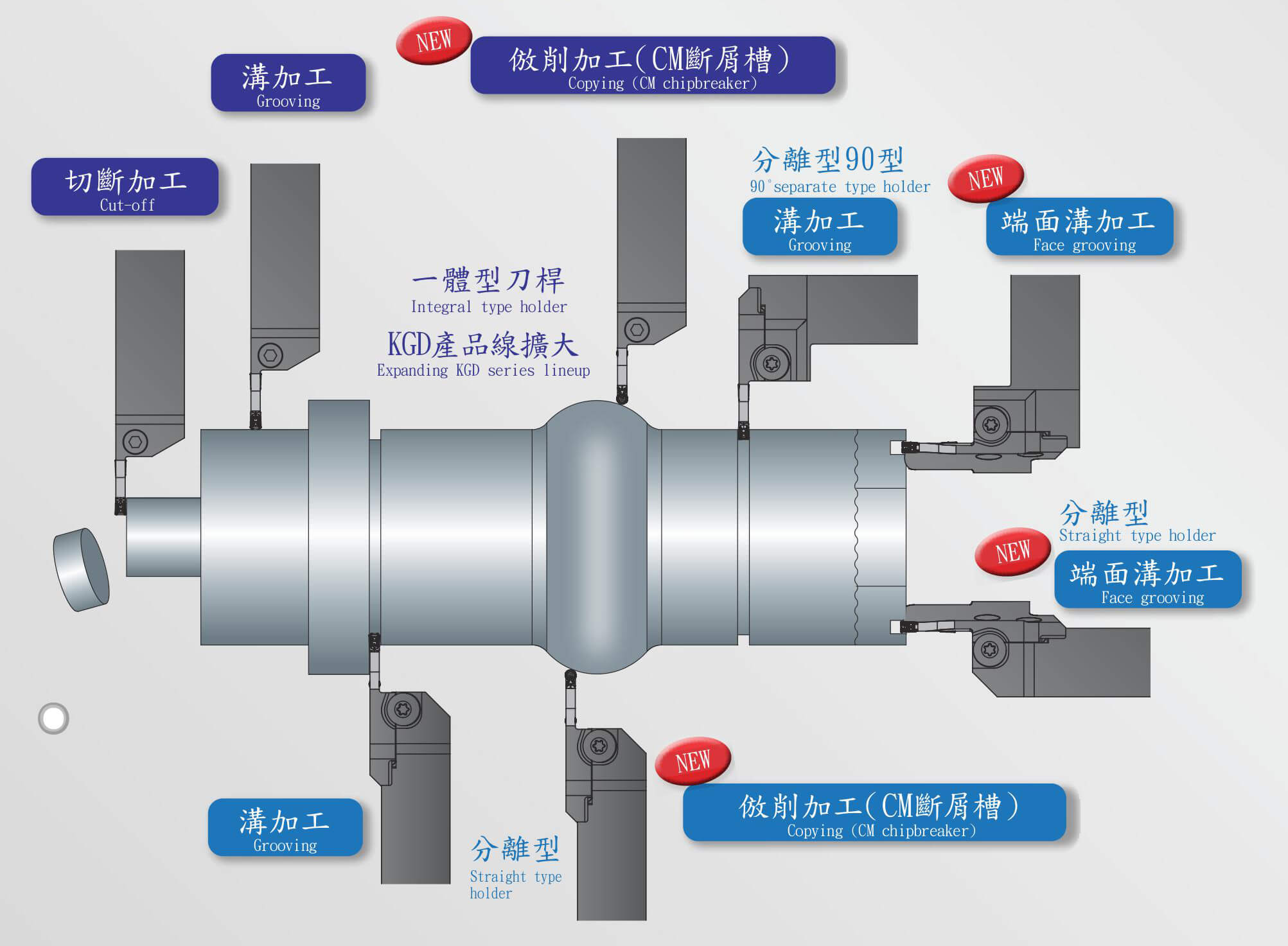

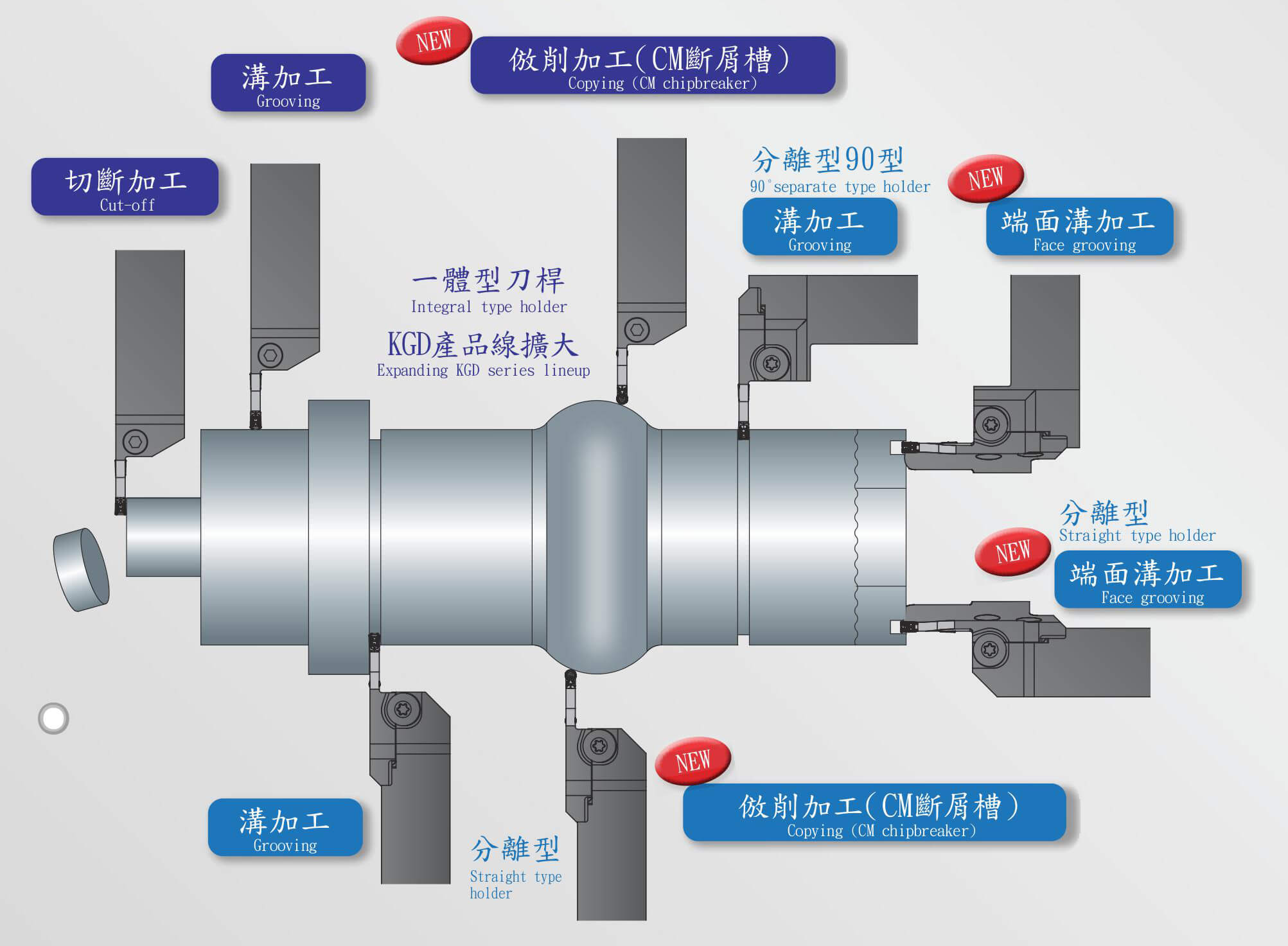

2.多樣化刀桿產品線 Various Toolholder lineup

-

KGD型/KGDF型槽溝系列 KGB / KGDF type grooving tol series

- 一體型刀桿:寬廣的刀桿產品線

Integral type toolholder with wide lineup (for various groove width and depth)

- 分離型刀桿:藉由更換刀板對應多樣化端面及外徑的槽溝及切斷加工

Separate type toolholder : Applicable for various types of grooving and cut-off, such as external and face cutting by replacing blade parts.

一體型/分離型應用參考

Integral type / Separate type Selection Reference

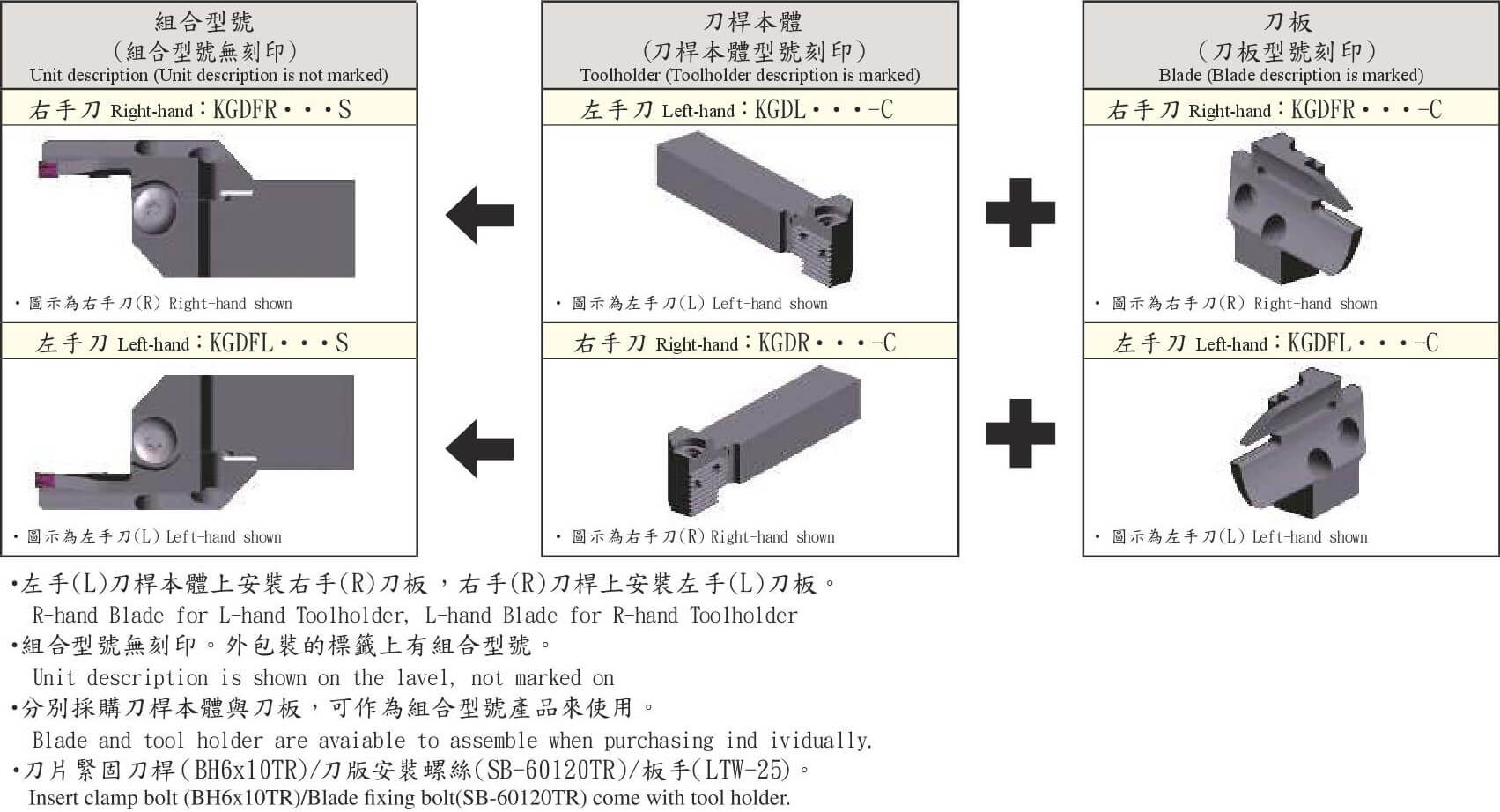

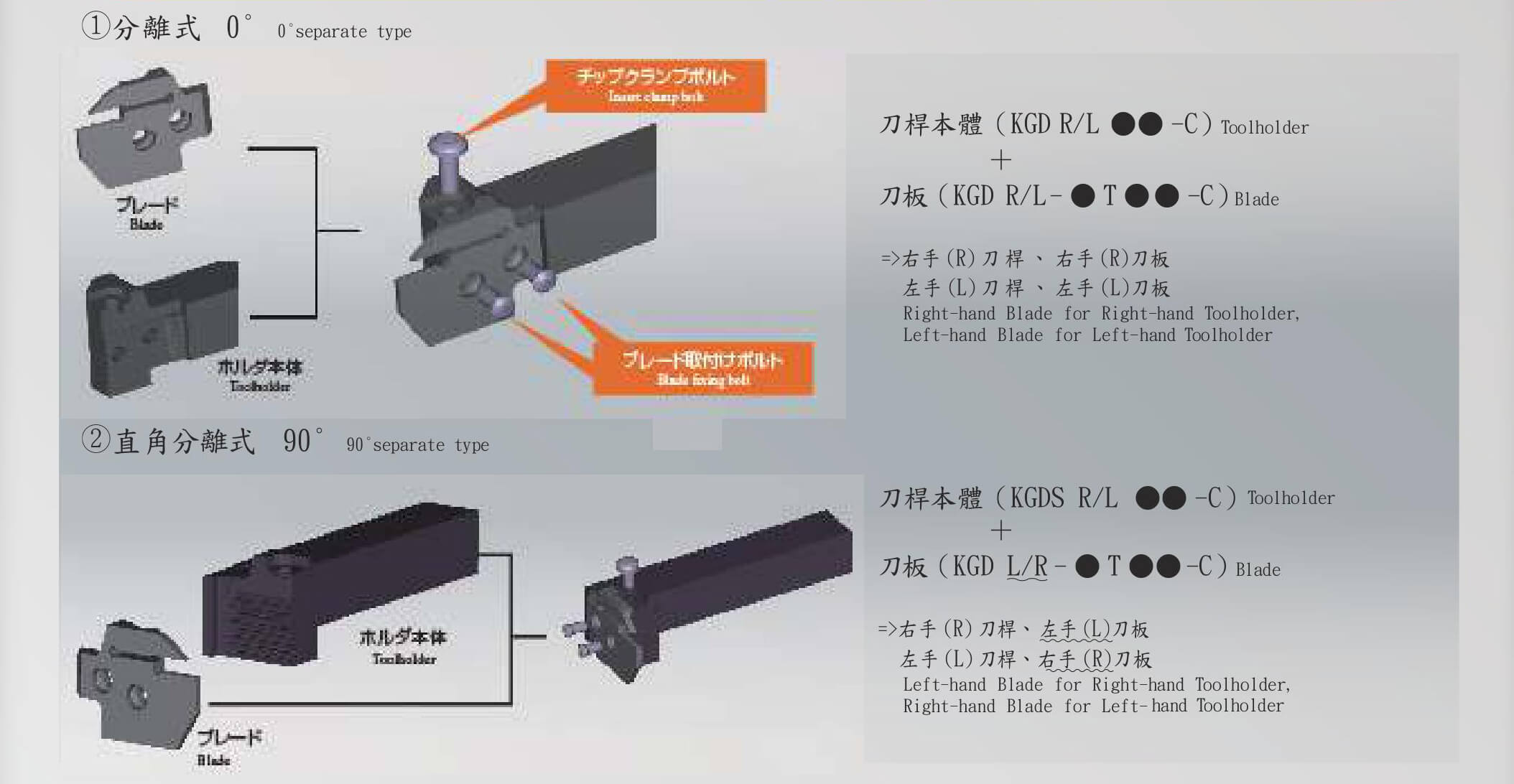

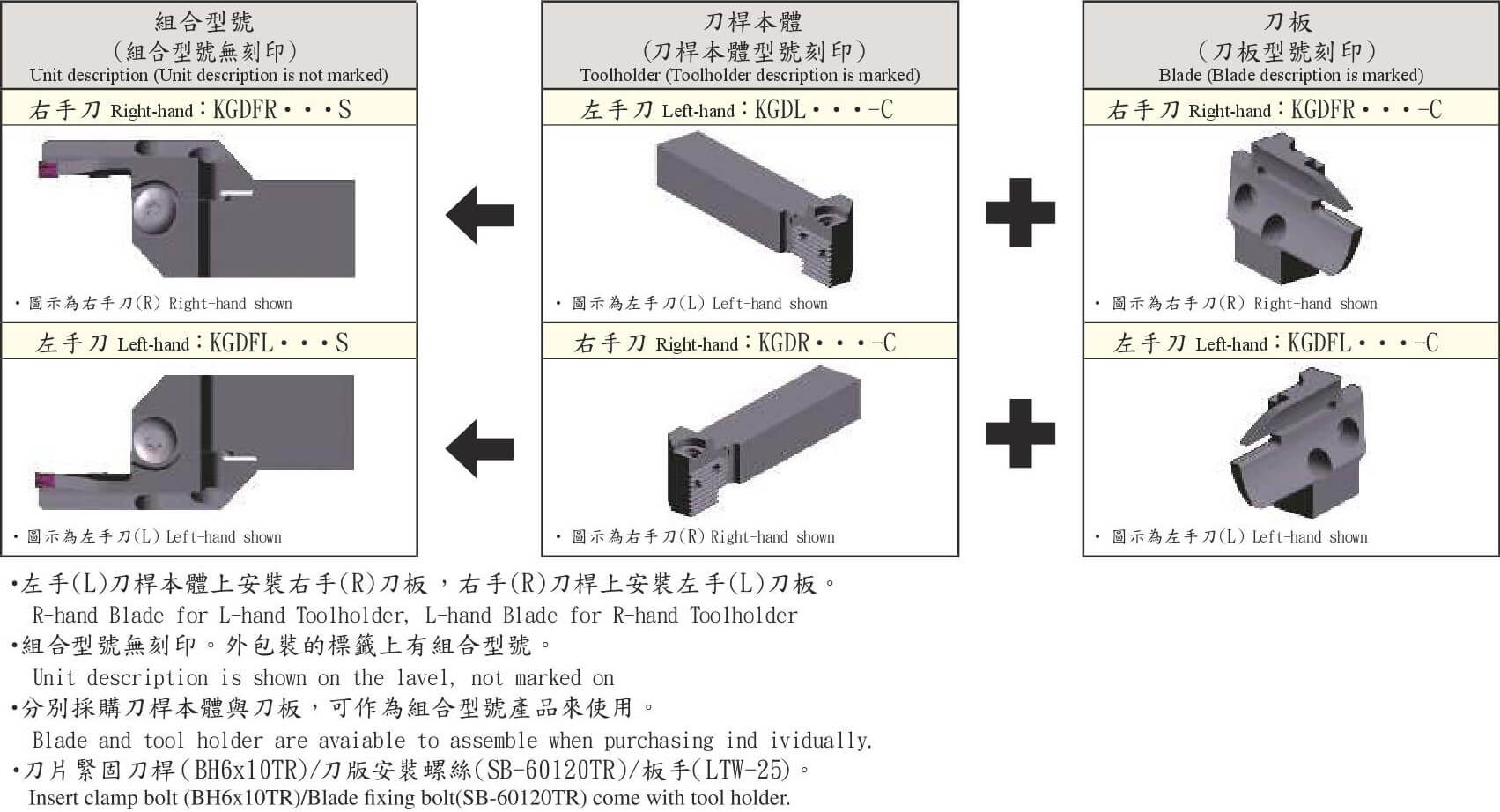

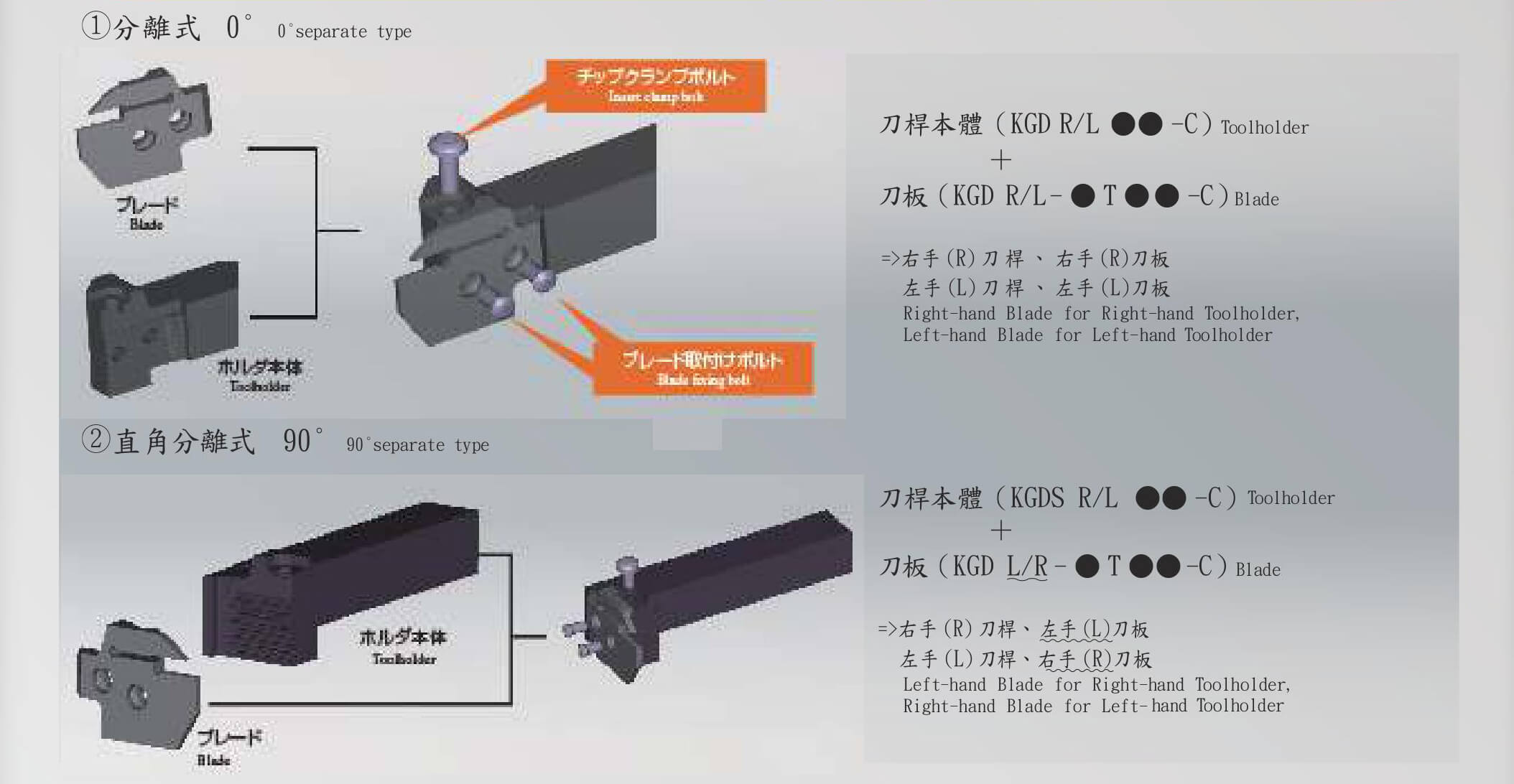

刀桿本體+刀板組合(外徑 • 橫移 • 切斷)

Combination of Toololder & Blade (for Face Grooving)

刀桿本體+刀板組合(端面槽溝)

Combination of Toololder & Blade (for Face Grooving)

適合刀片

適合刀片(溝+橫移)

Applicable Inserts (Grooving & Traversing)

適合刀片(切斷PM斷屑槽)

Applicable Inserts (Grooving & Traversing)

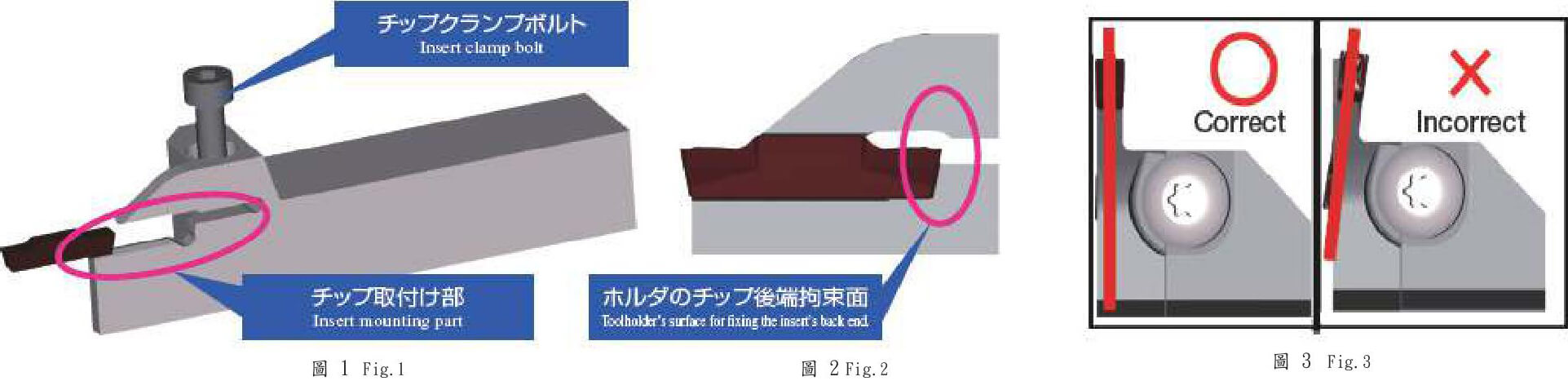

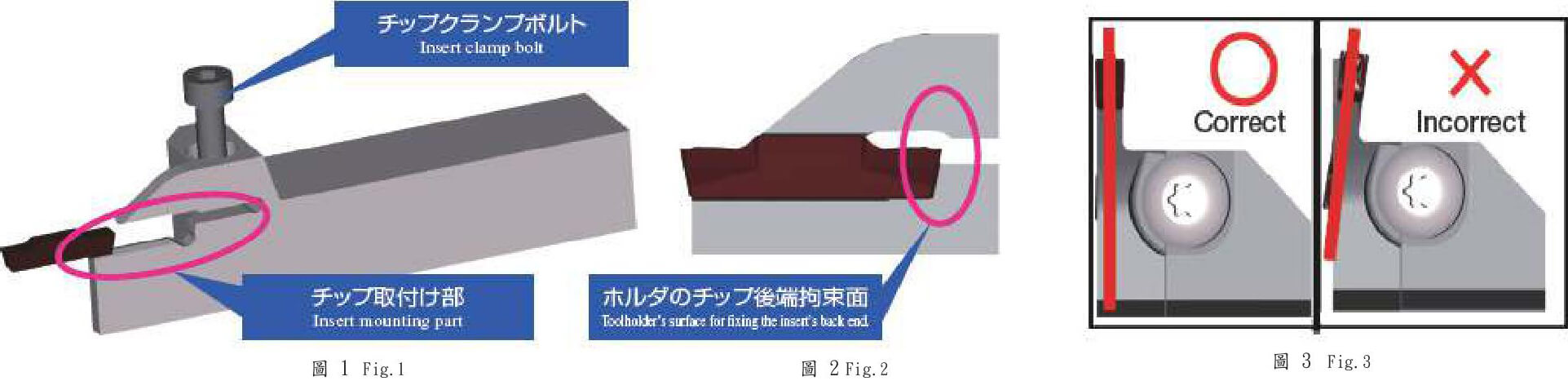

安裝刀片的程序

Setting the insert (Common procedure for integrated and separate types)

- 使用吹風或其他工具讓刀片夾持的部位完全去除鐵屑桿(圖1参照)。

Make air blow or other measures to completely eliminate chips from the insert mounting part (Fig. 1).

- 將刀片安裝在刀桿上,輕推讓刀片底部接觸到夾持部位的面(圖1圖2參照)。

Set the insert to the toolholder and push until it contacts with the toolholder’s surface for fixing the insert’s back end (See Fig. I and Fig.2).

- 使用適當的扭力鎖緊夾持螺栓(建議扭力:6.5N -m 8mm宽8 Nem))。

Keeping the insert fit to the toolholder’s surface, tighten the insert clamp bolt at an appropriate torque. (Recommended tightening torque : 6.5 Nm (8Nem for 8mm width))

- 使用前確認刀桿與刀片間沒有縫隙,並且注意刀片是否有倾斜(圖2圖3參照)。

Before using the unit, make sure that no gap is between the insert and the toolholder’s surface, and that the insert is mounted without tilting (See Fig. 2 and Fig. 3).

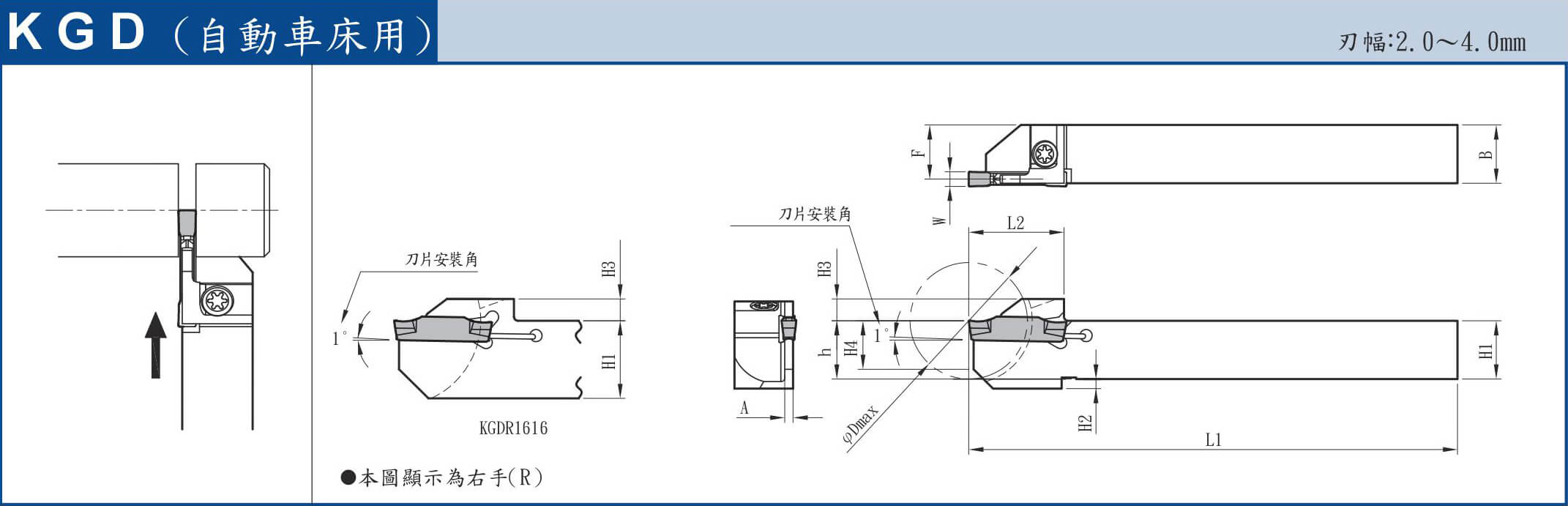

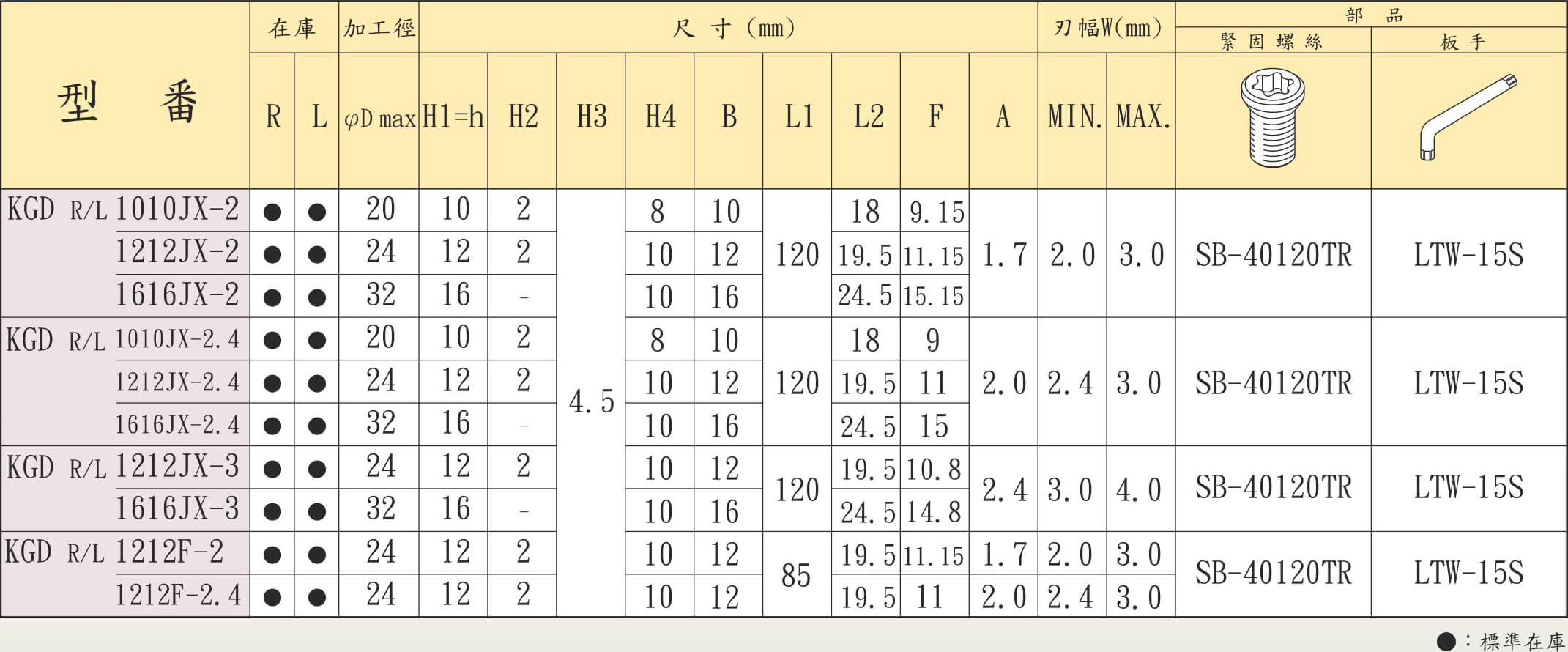

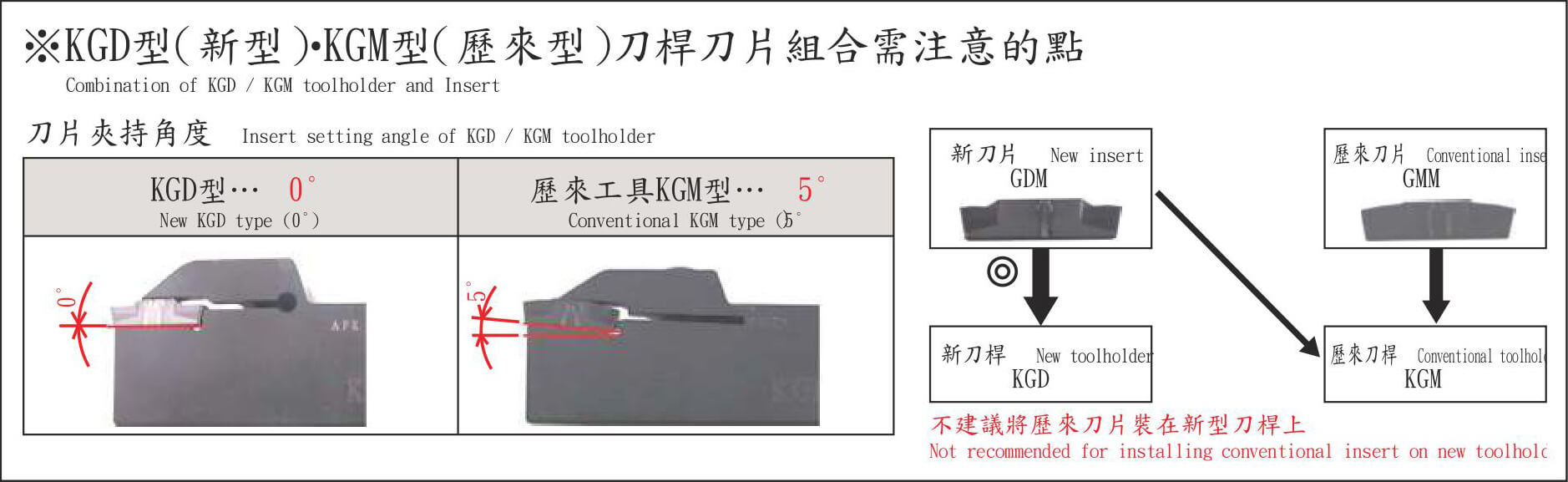

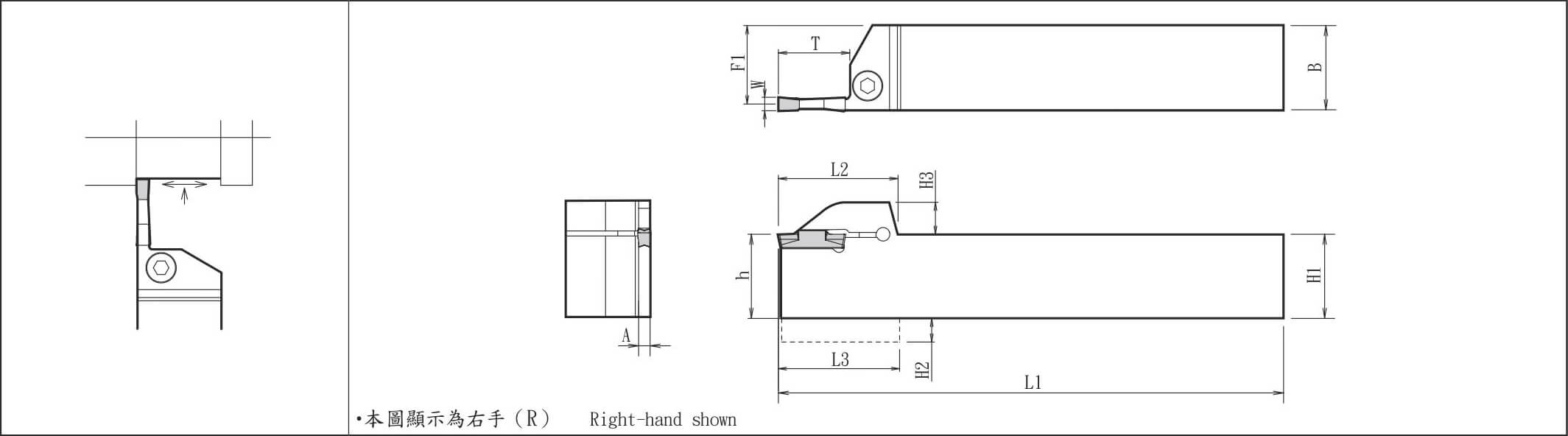

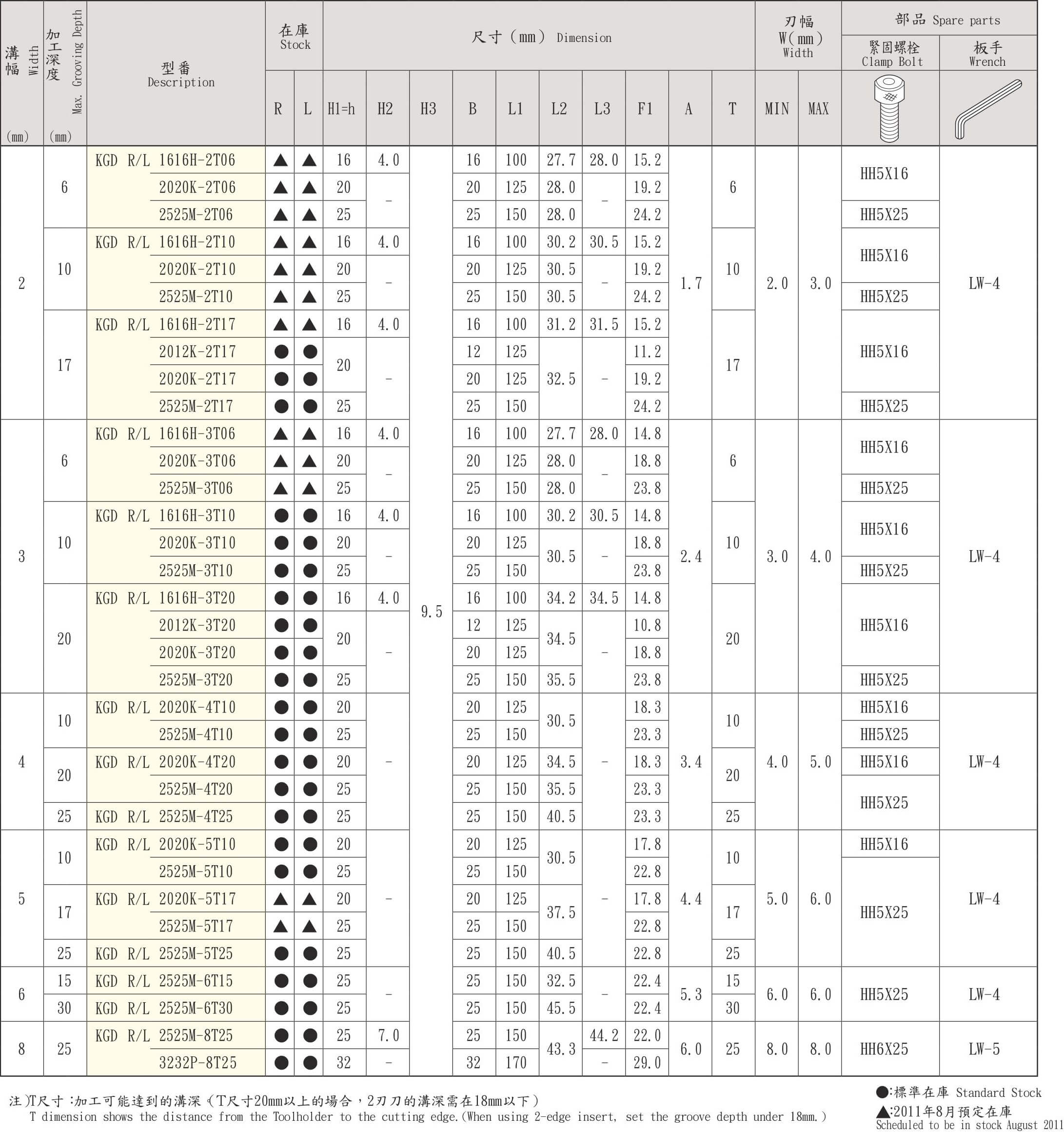

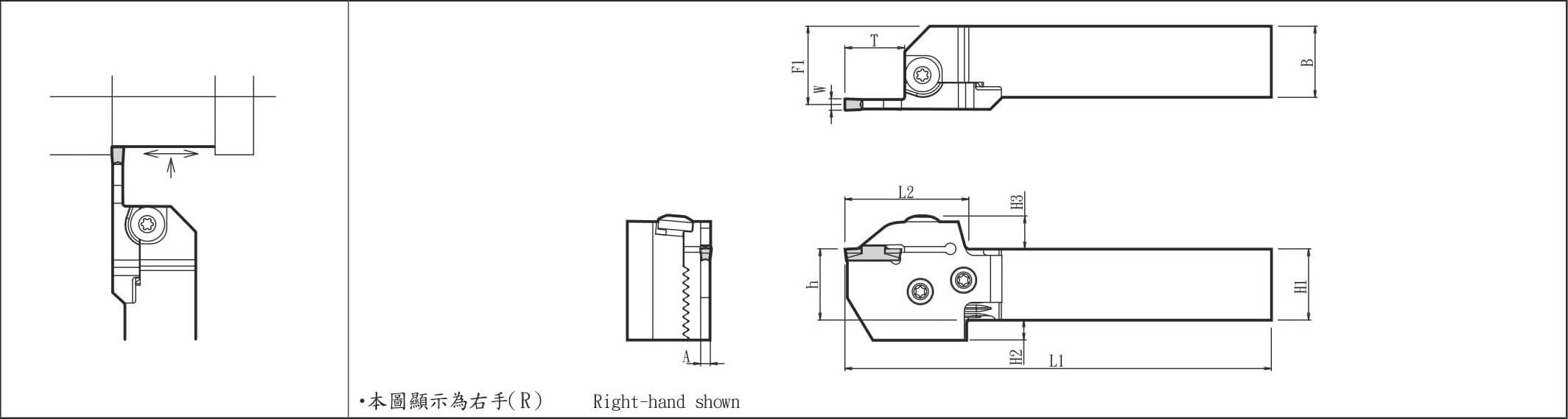

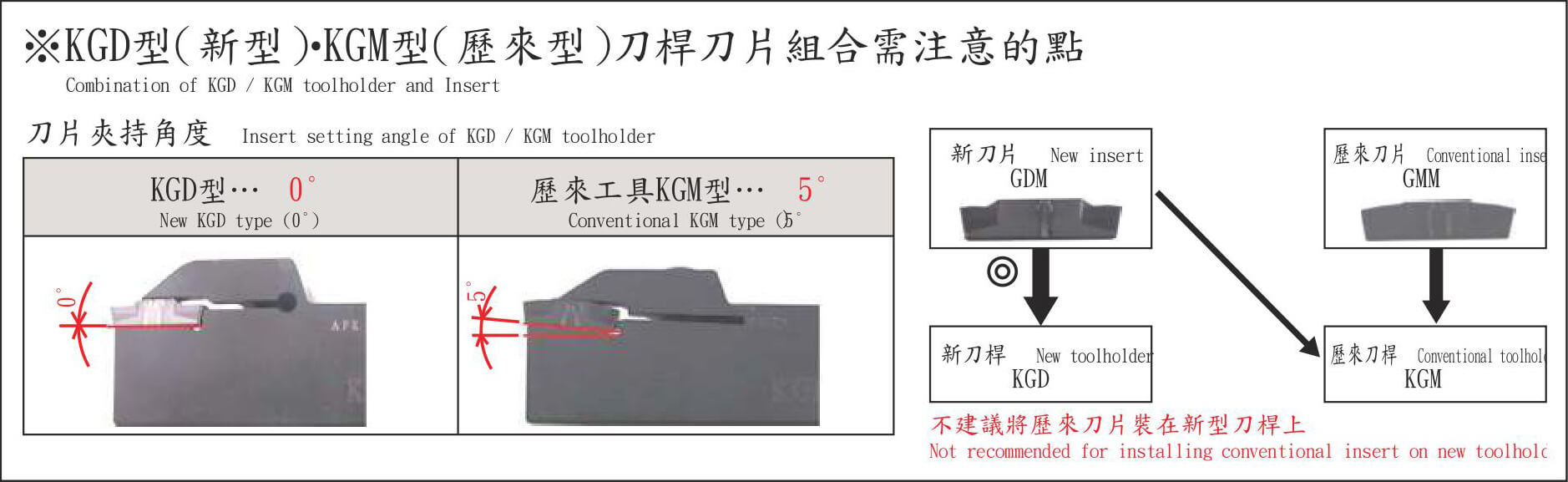

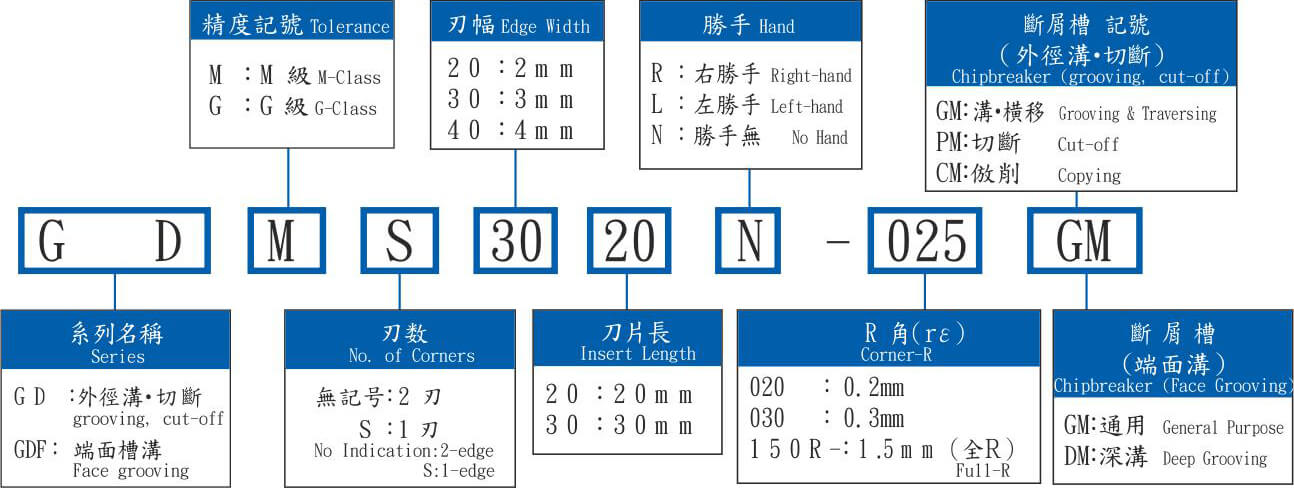

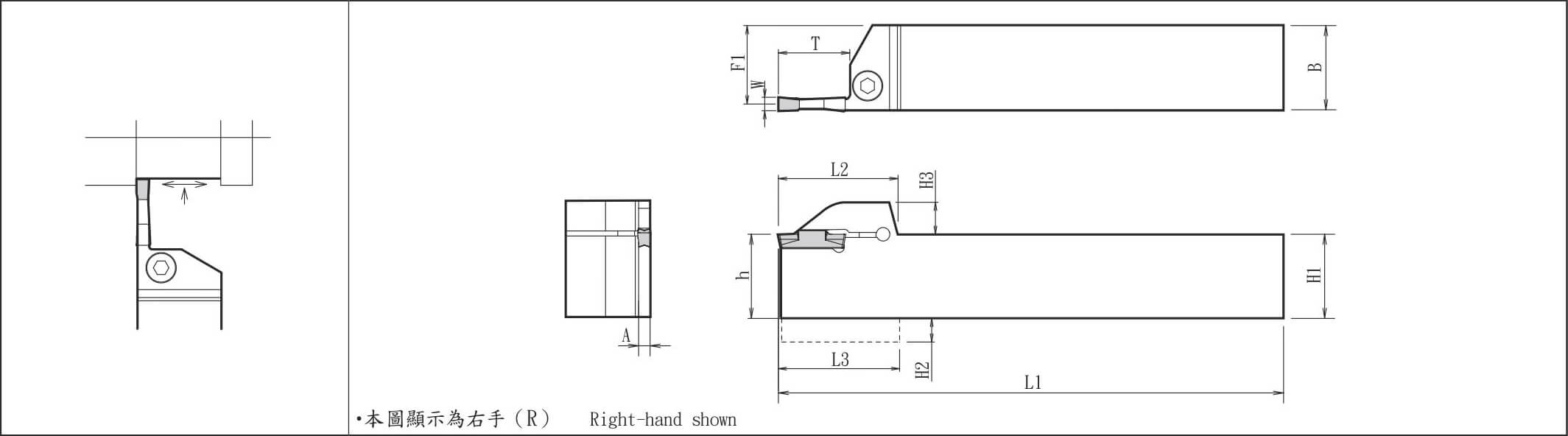

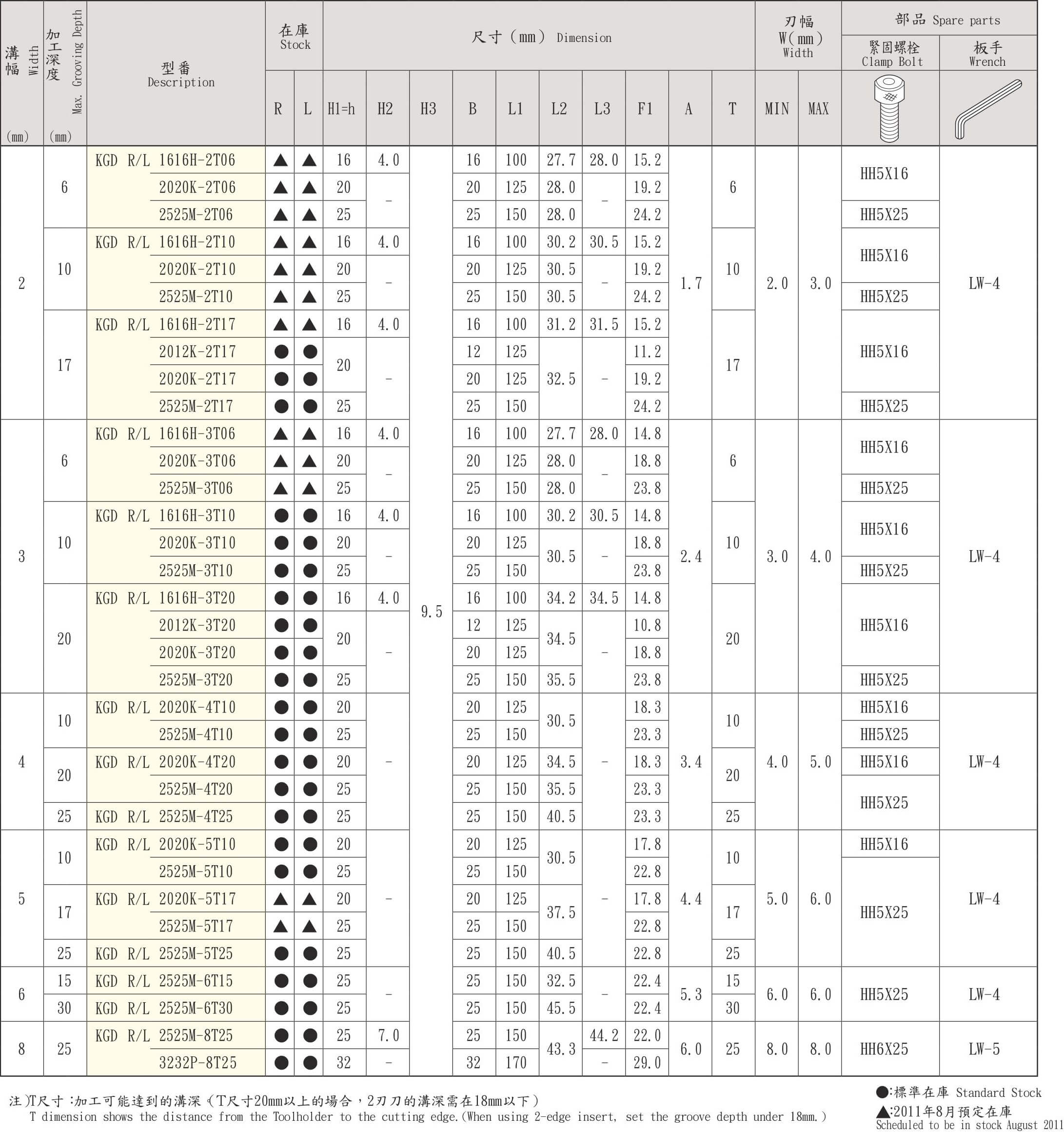

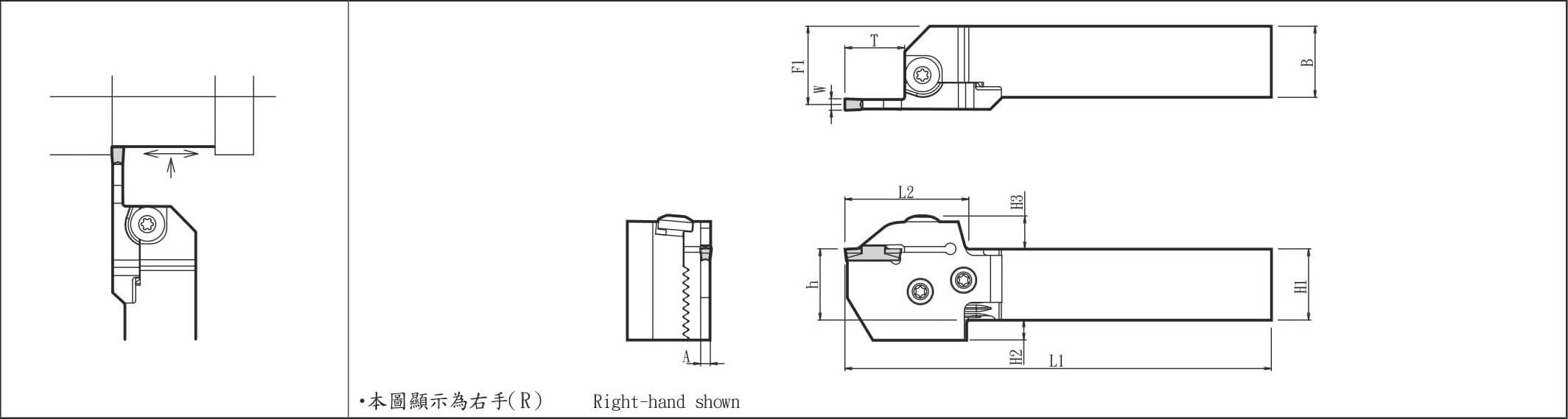

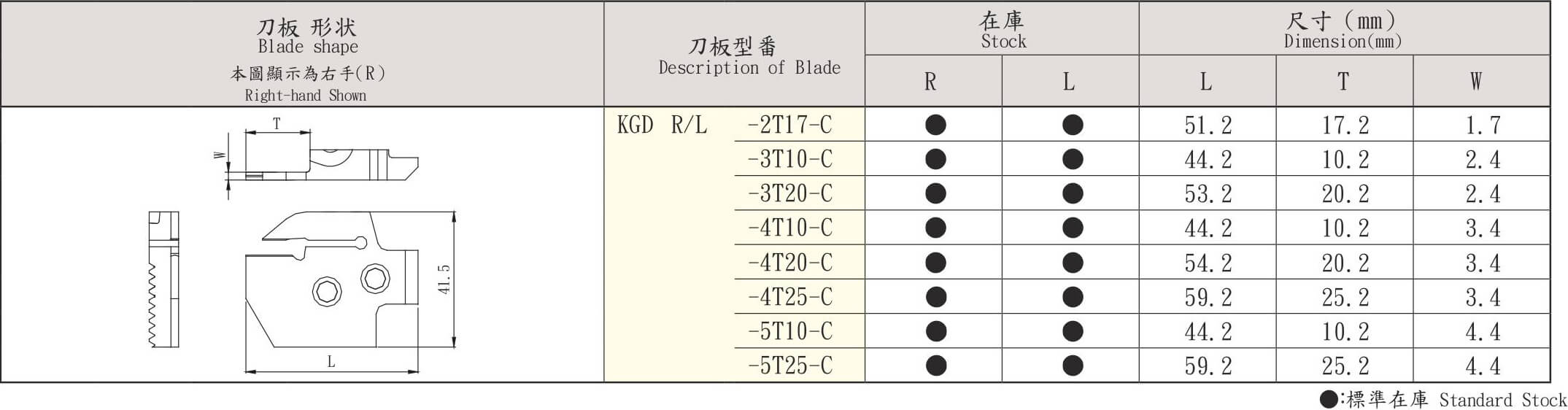

KGD型

KGD型(一體型)KGD type(integral type)

刀桿尺寸Toolholder dimensions

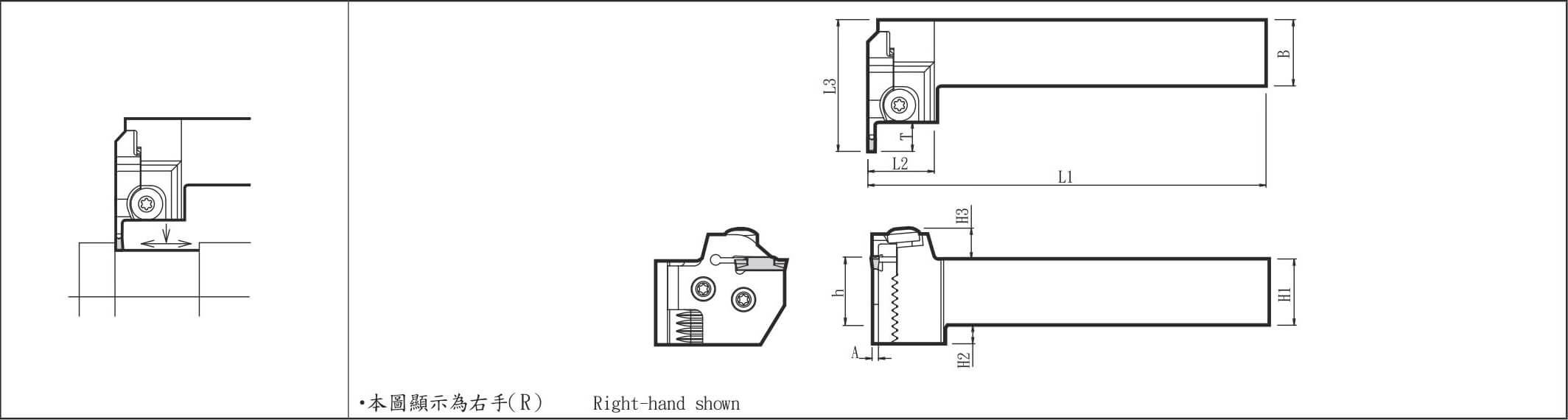

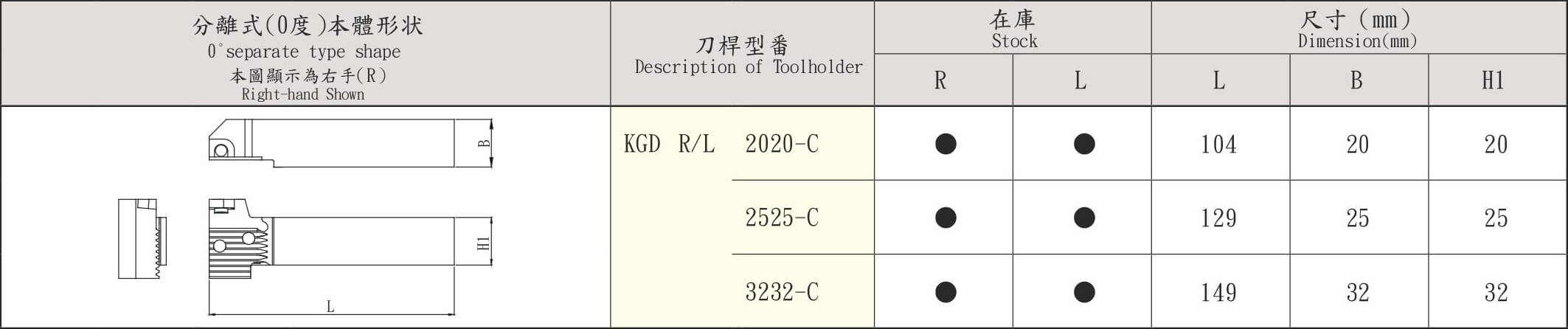

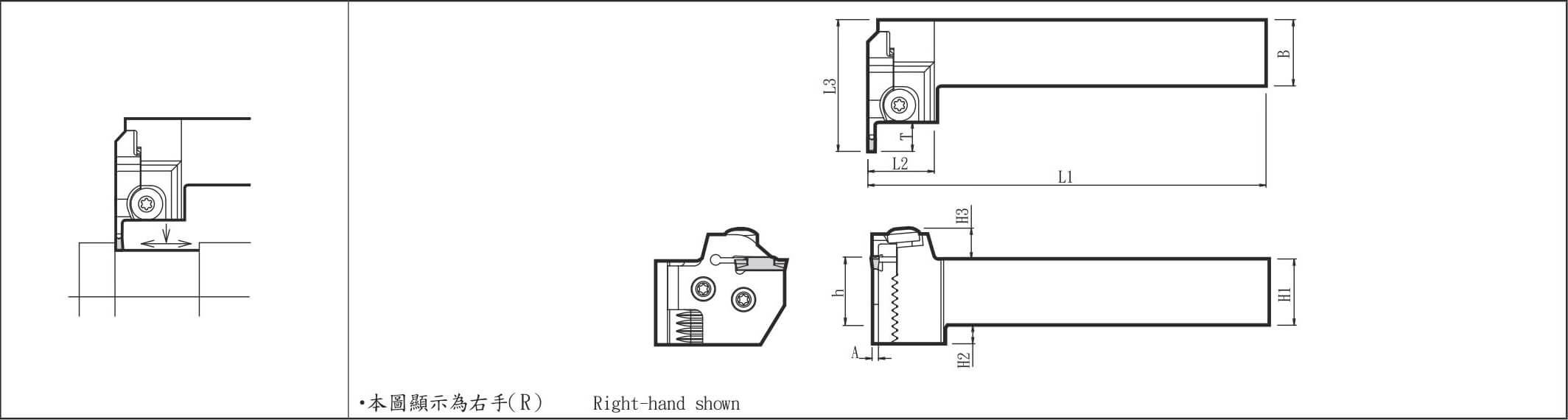

KGD-S型

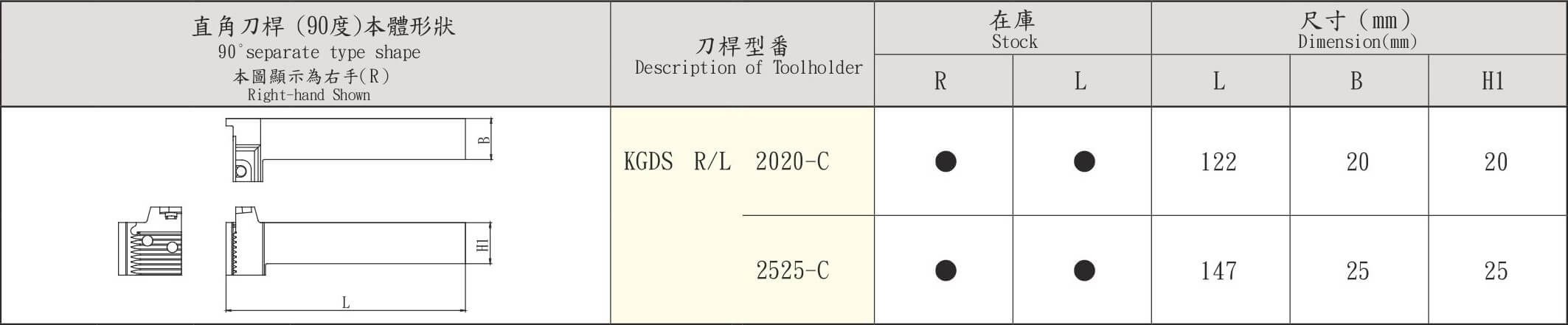

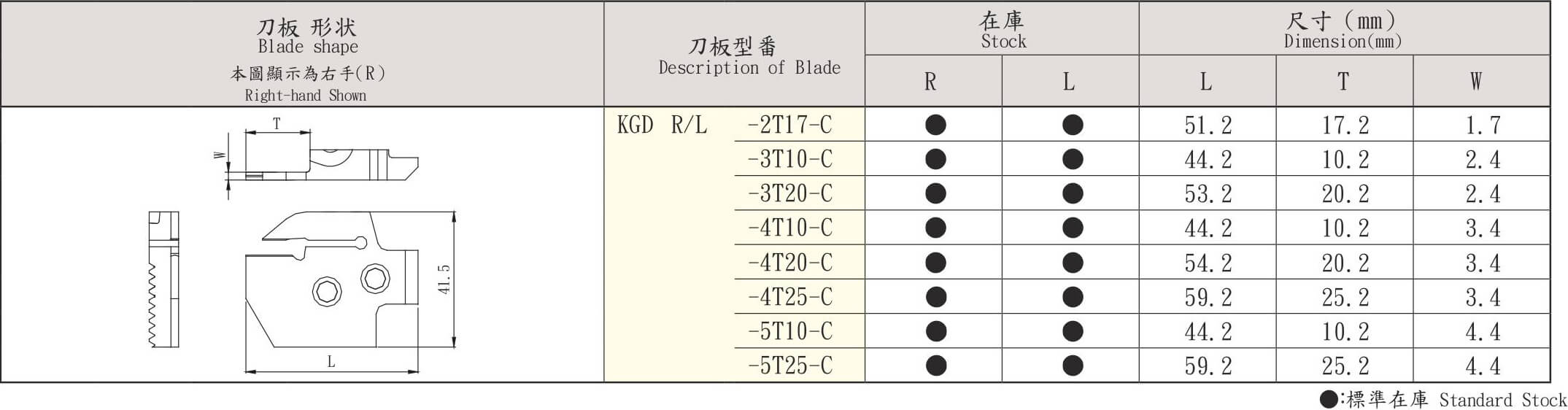

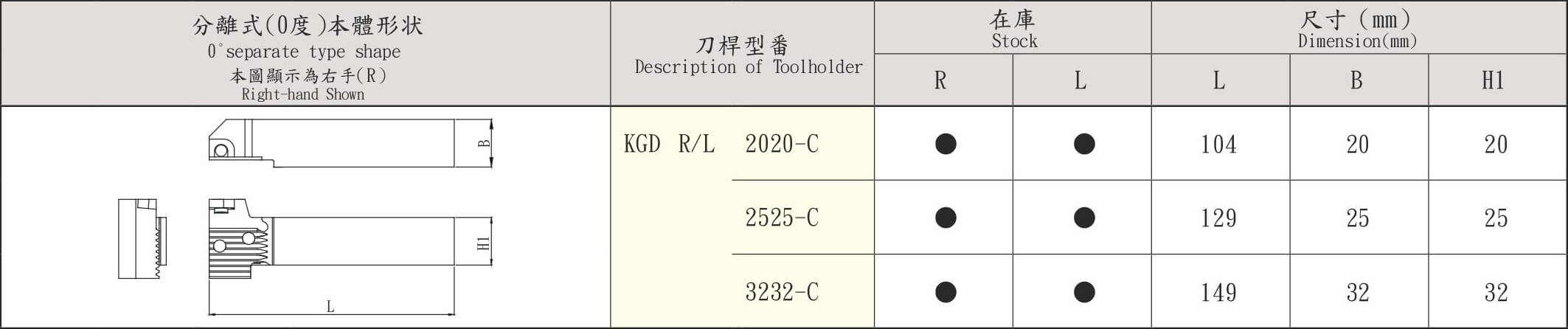

KGD-S型(0度 分離型)

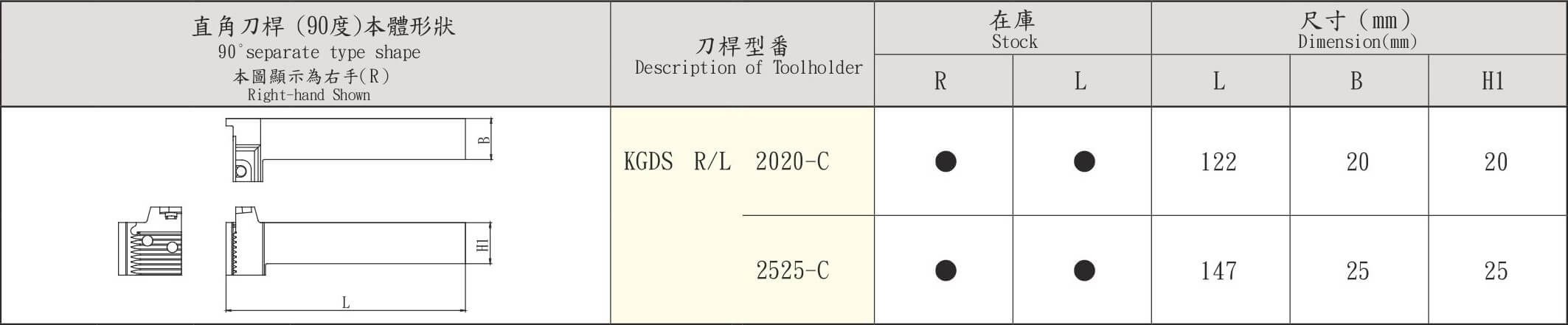

KGD-S型(直角90度 分離型)

刀桿尺寸(刀桿本體+刀板) Toolholder dimensions(toolholder and blade)

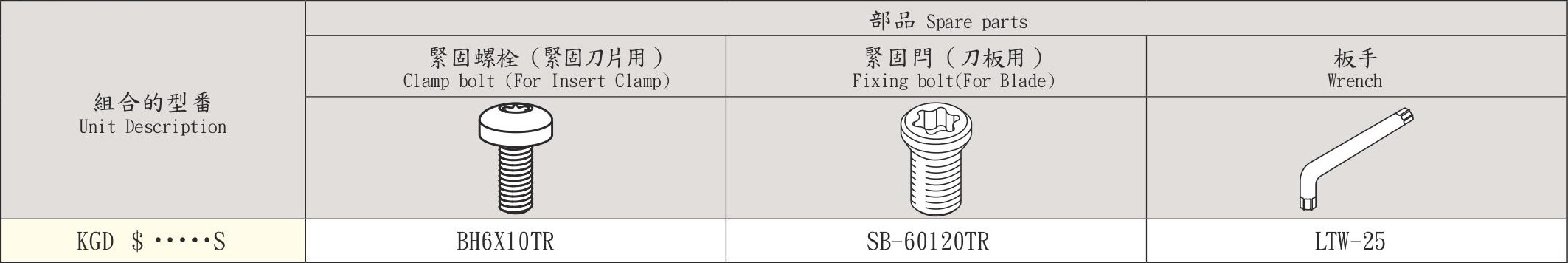

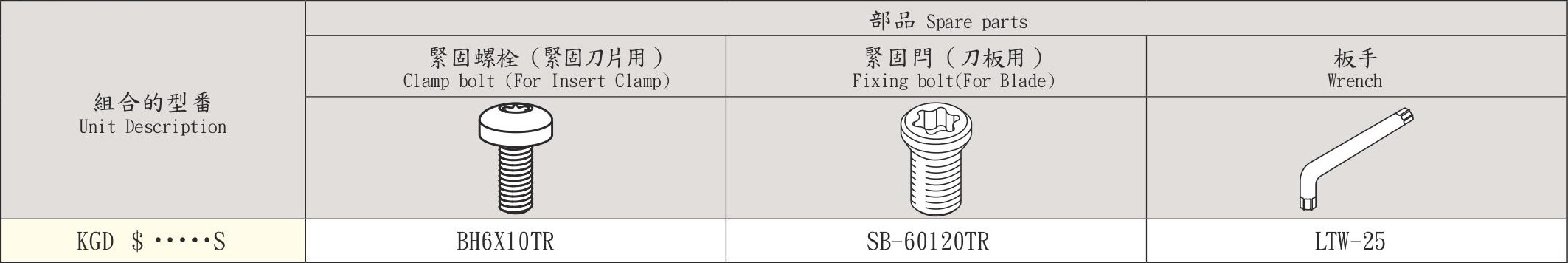

部品Spare parts

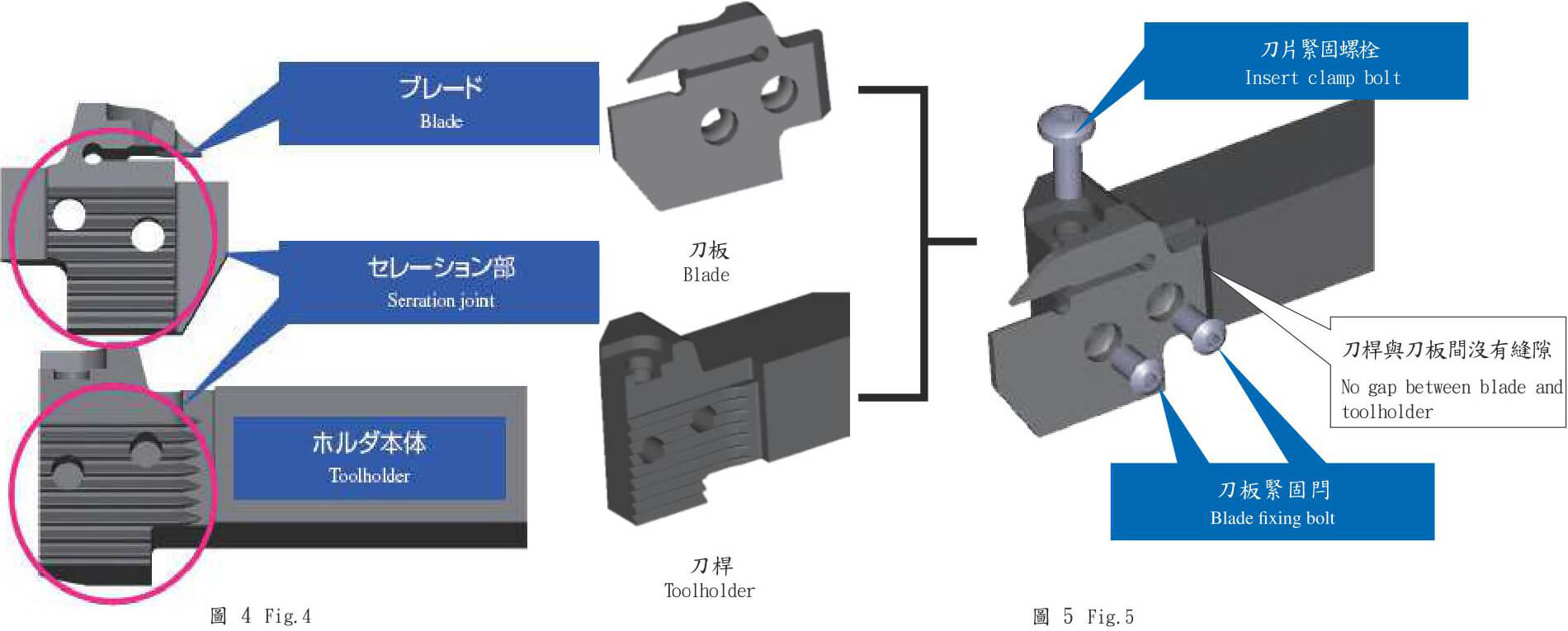

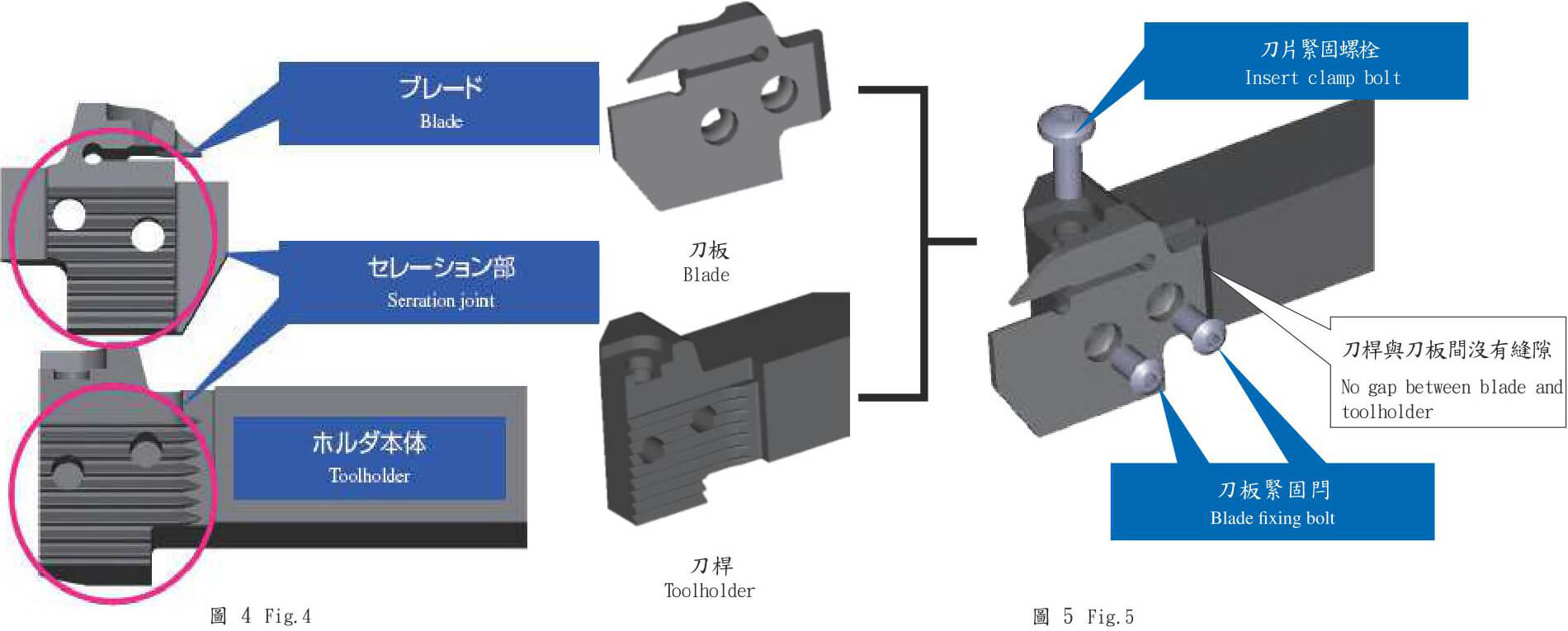

組裝刀板(分離型刀桿)

Setting the blade(Separate-type toolholder)

- 使用吹風或其他工具讓刀片夾持的部位完全去除鐵屑桿(圖4参照)。

Make air blow or other measures to completely eliminate chips from the insert mounting part (Fig. 4).

- 將鋸齒狀的刀桿與刀板做緊密結合(圖5參照)

Fit closely the serration joins of the blade anf toolholder (See Fig.5)

- 使用適當的扭力鎖緊刀板(建議扭力:8 N -m)(圖5參照)。

Tighten the blade fixing bolts at an appropriate torque(Recommended tightening torque:8N-m).You can tighten them in any order(See Fig.5).

- 裝好刀板後將刀片安裝上去

Set the insert after setting the blade.

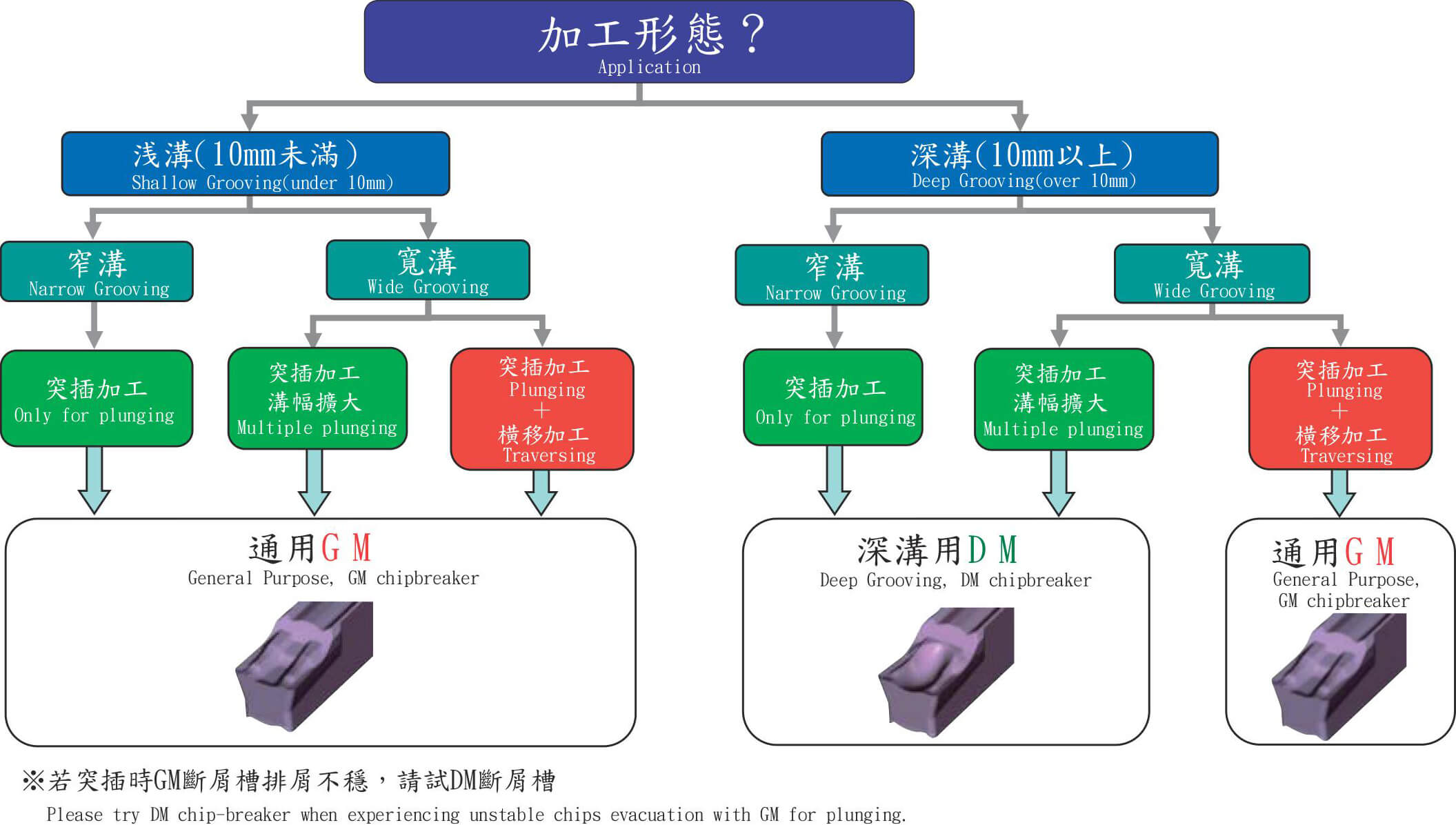

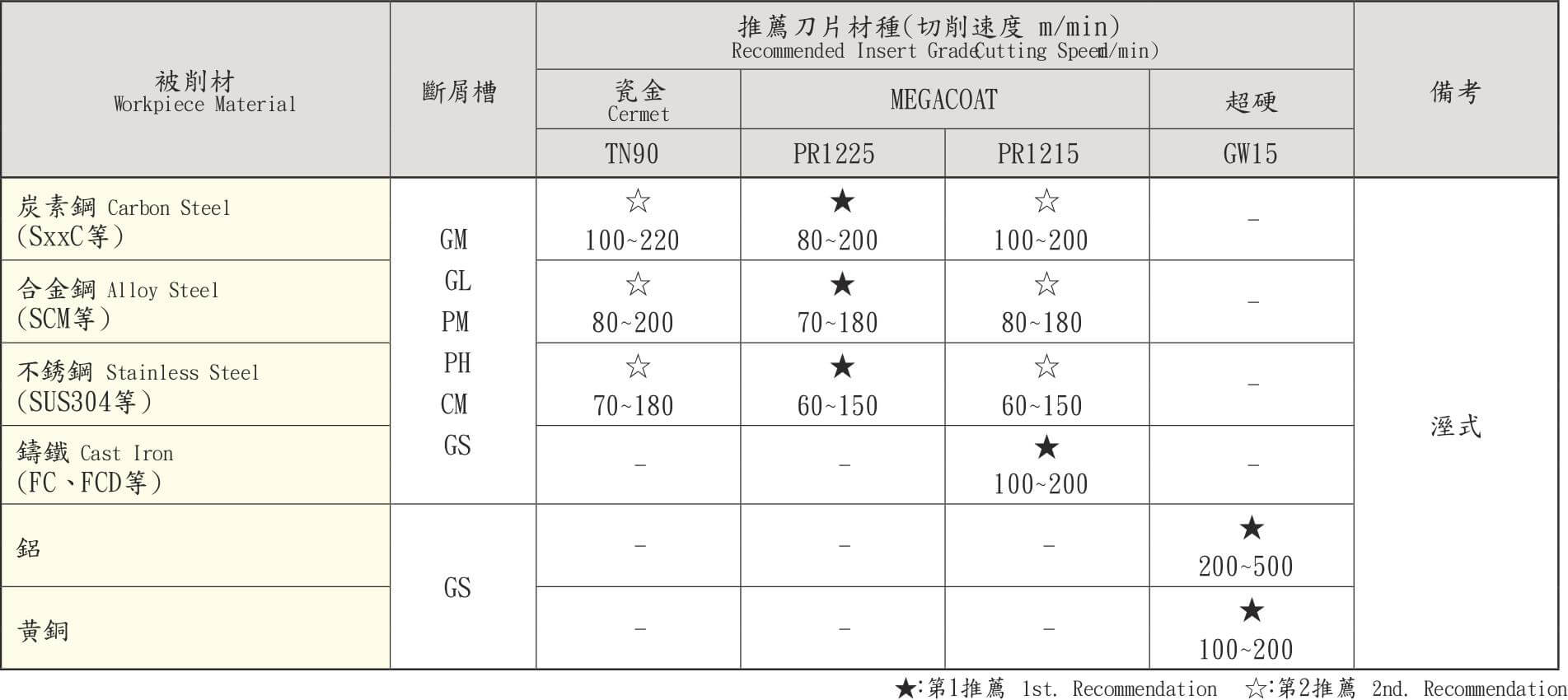

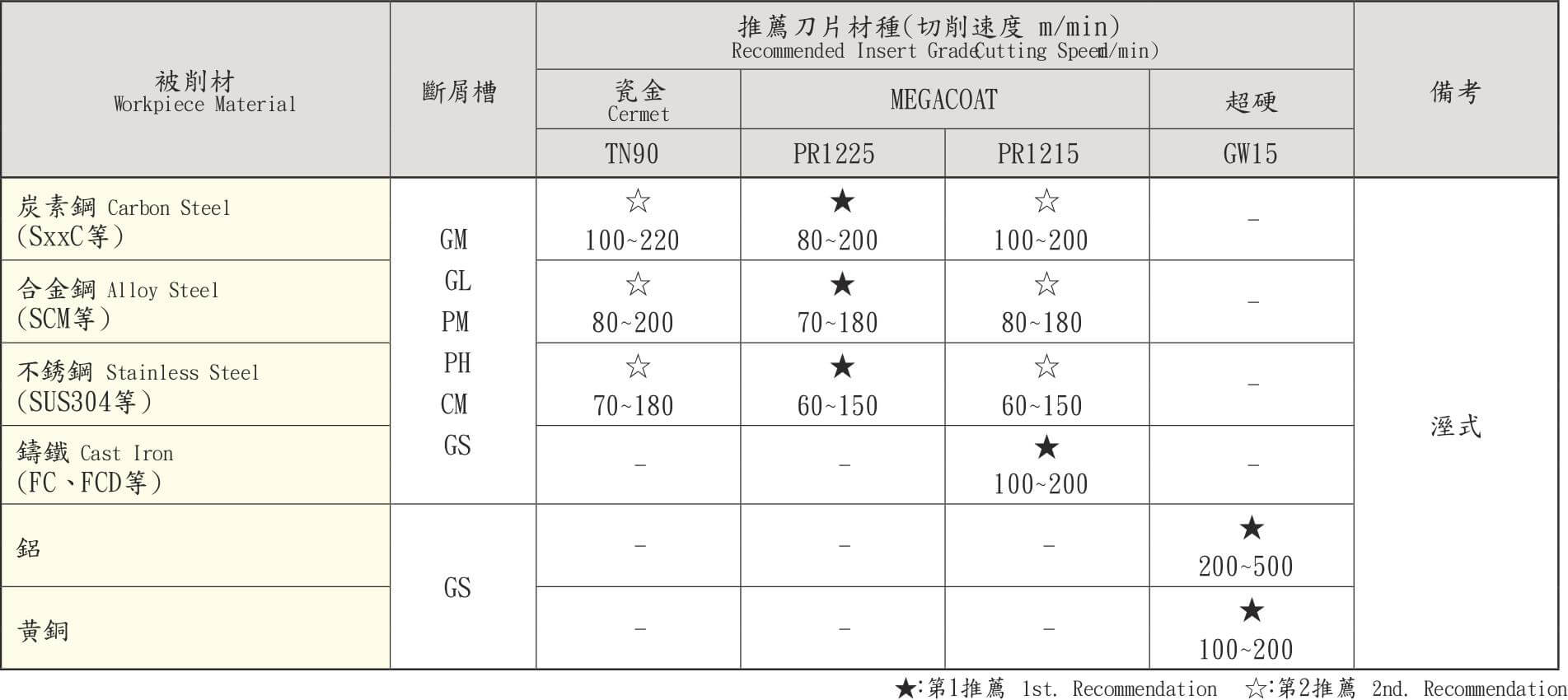

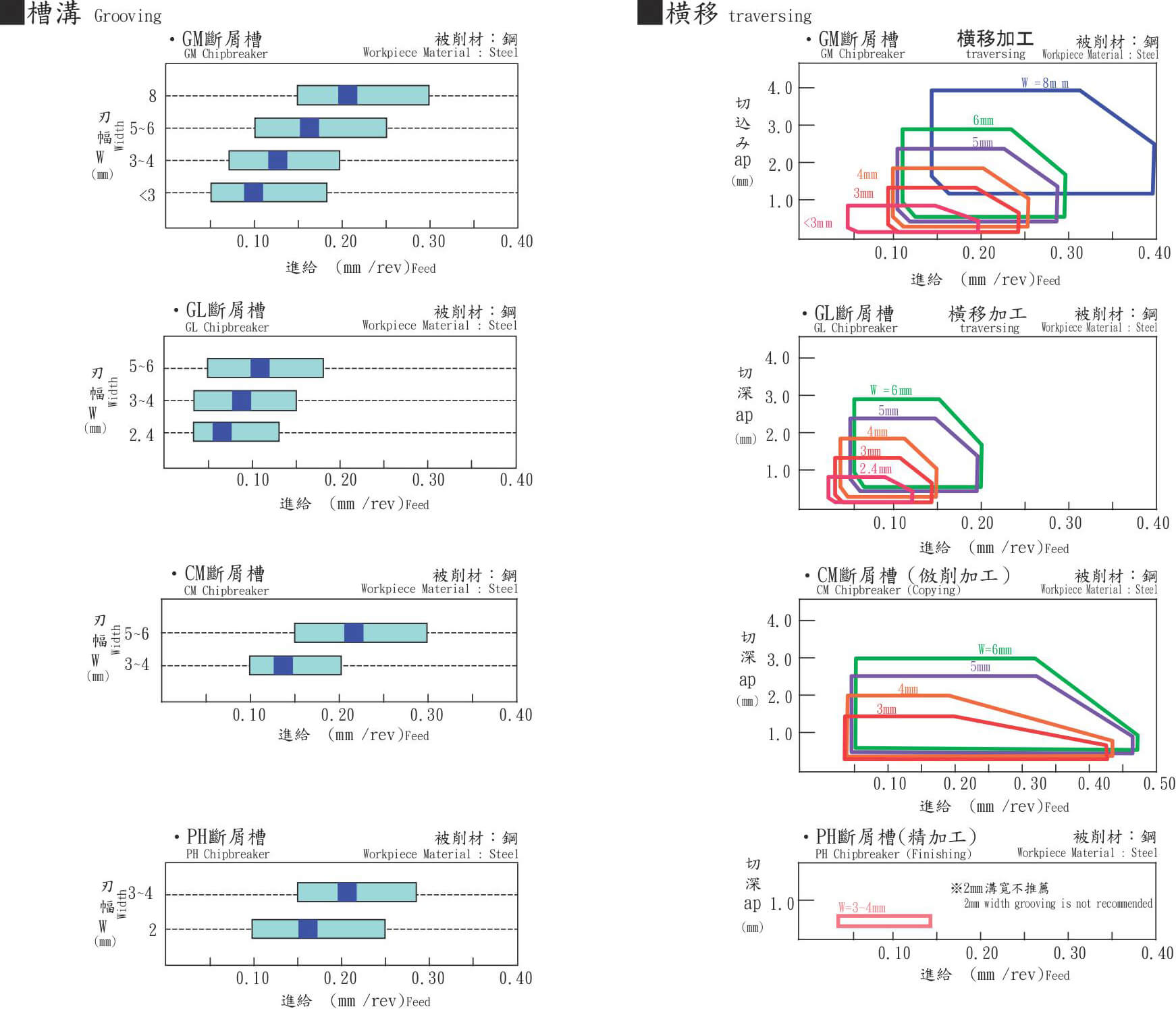

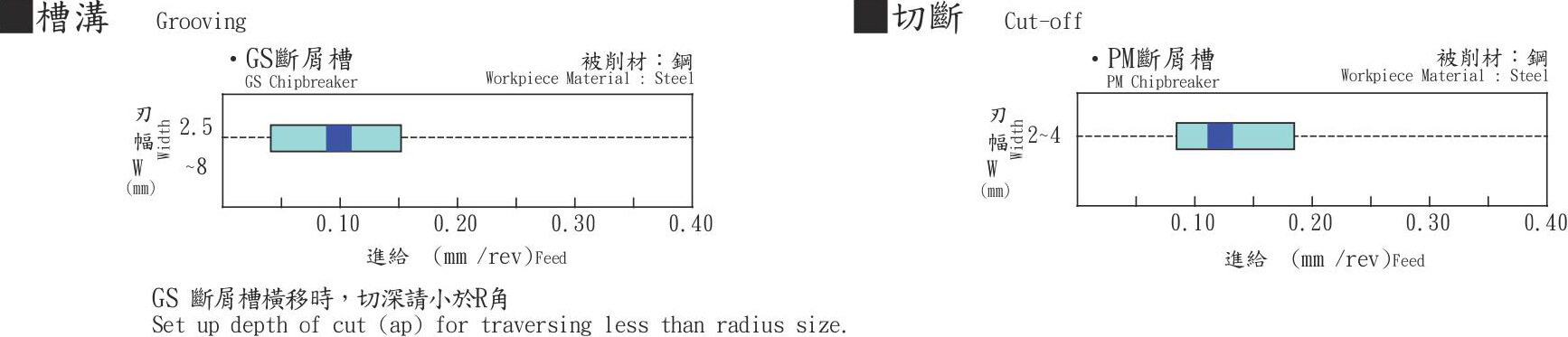

推薦切削條件

推薦切削條件(外徑溝 • 切斷)

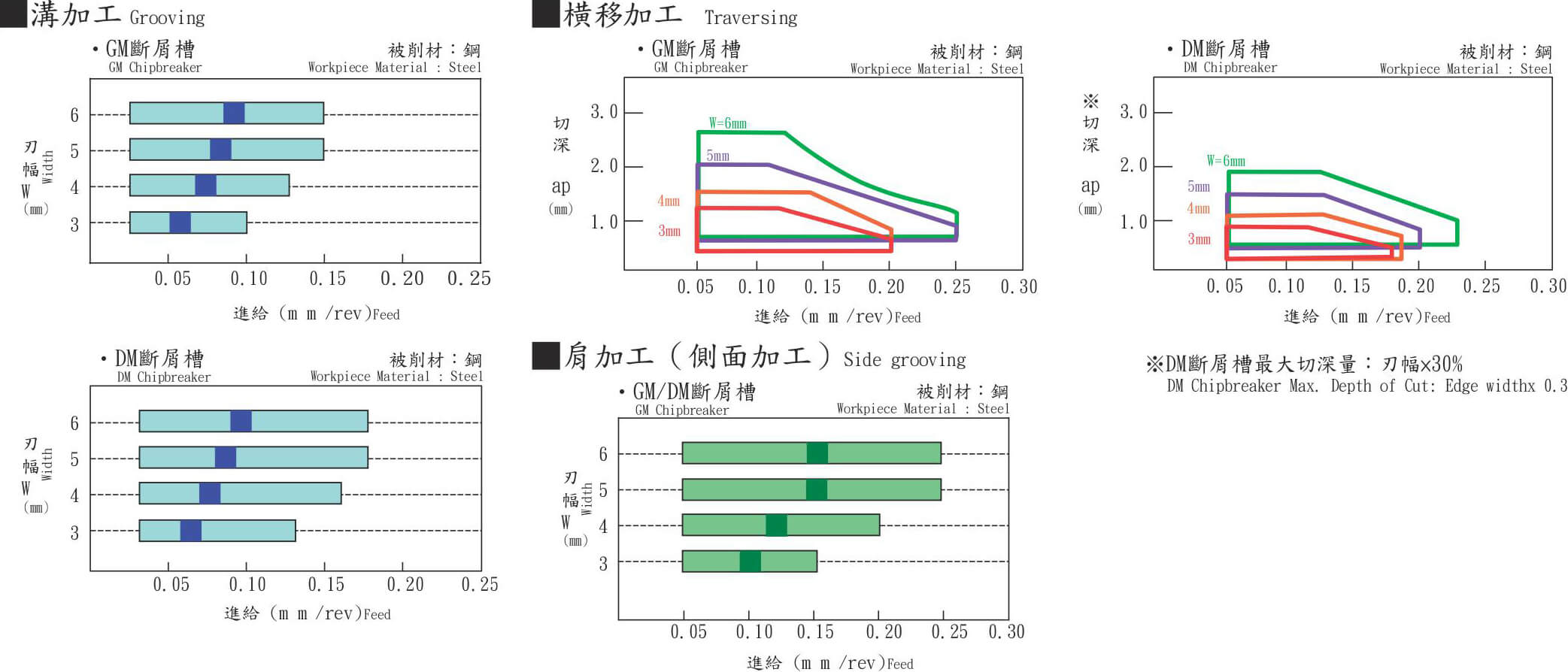

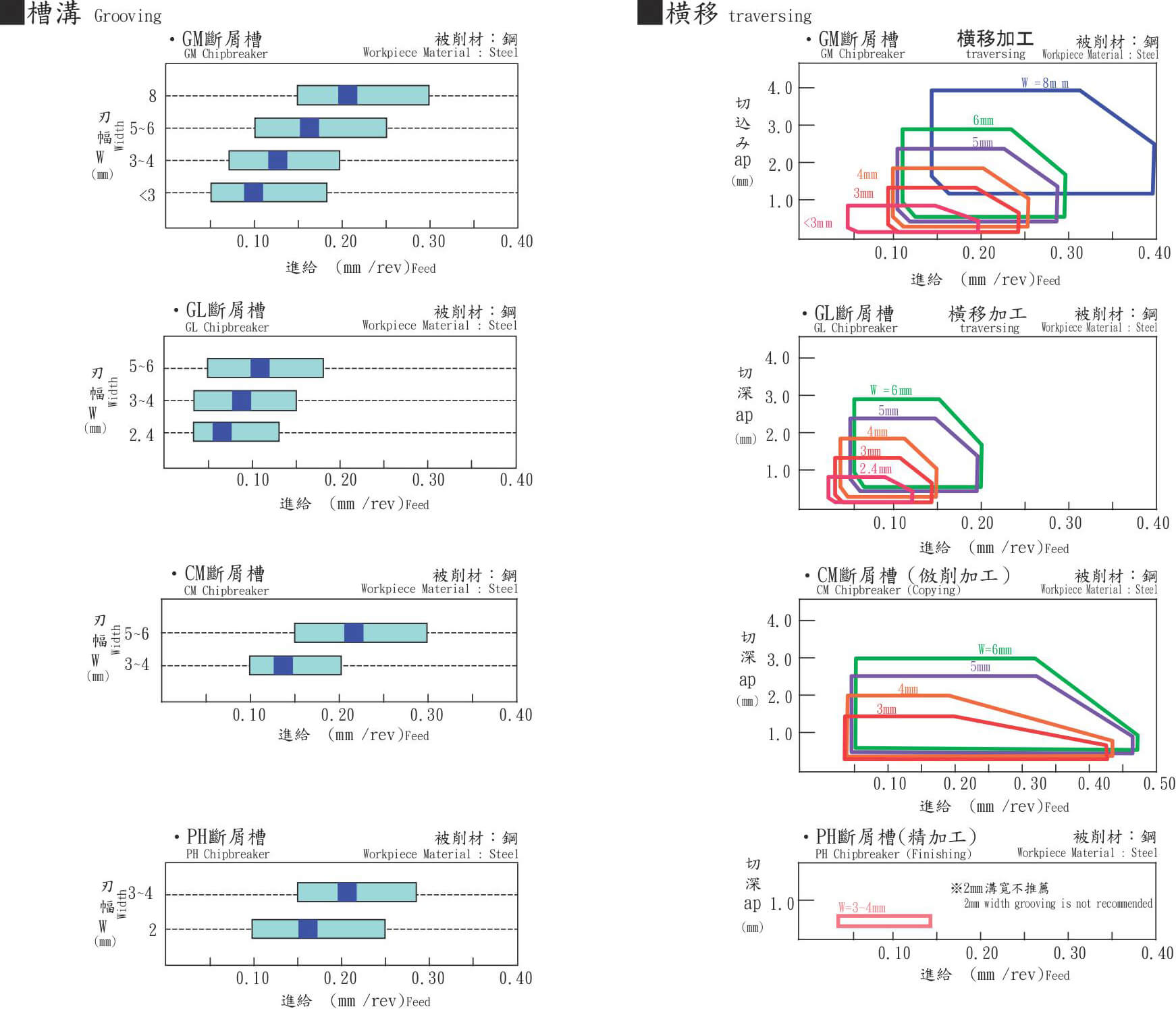

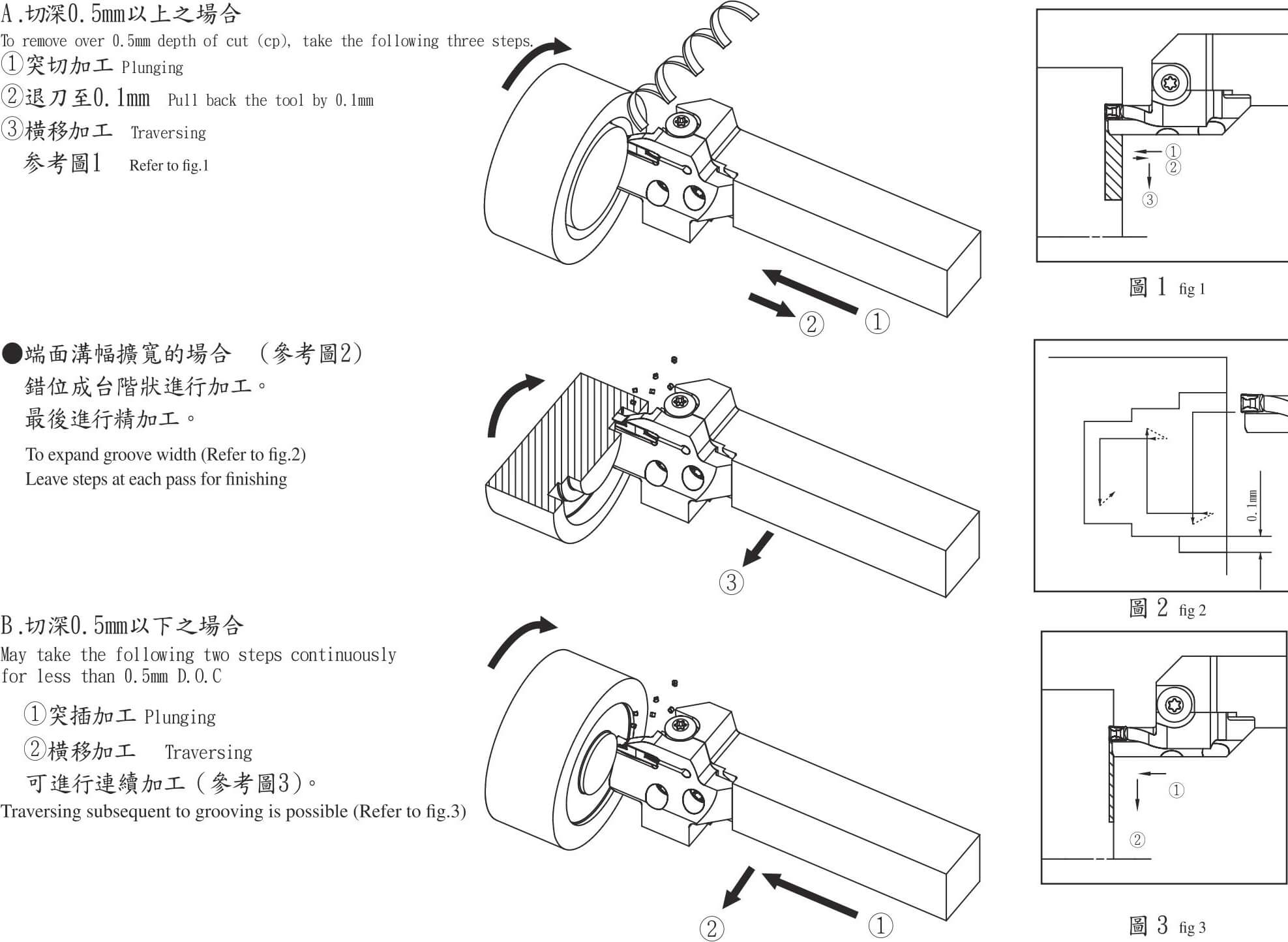

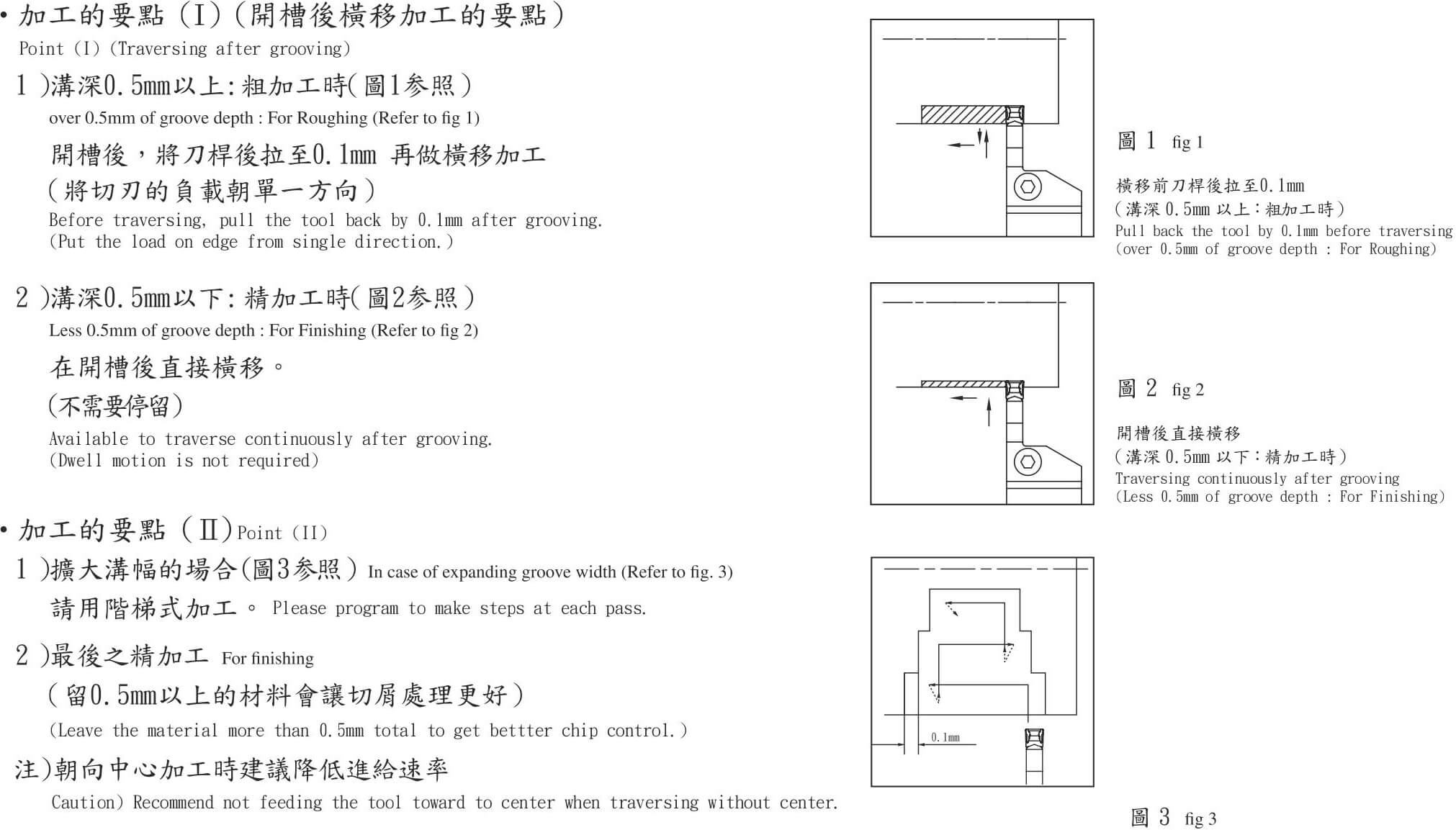

推薦切削条件(進給、切深)

Recommended Cutting Conditions(f, ap)

- 上述條件為刀桿的T(溝深)在17mm以下

Above conditions are in case toolholder’s T dimension is under 17mm

- 若刀桿的T(溝深)在17m以上,除了刃幅8mm的之刀片,其他請用90%以下之條件做橫移

In case T dimension is more than 17mm for all too lholders except 8mm insert width type, use up to 90% of recommended cutting conditions at traversing.

推薦切削條件(進給) Recommended Cutting Conditions (Feed)

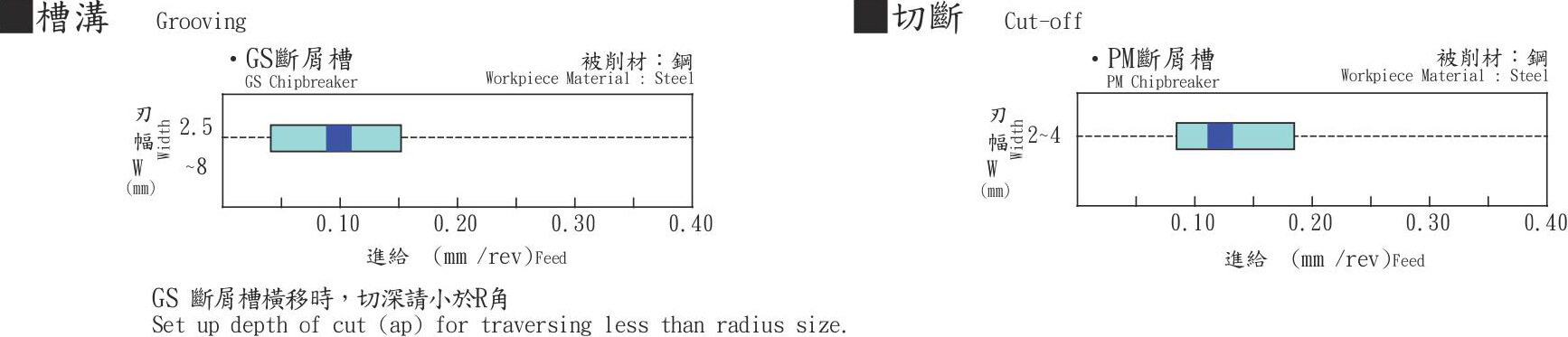

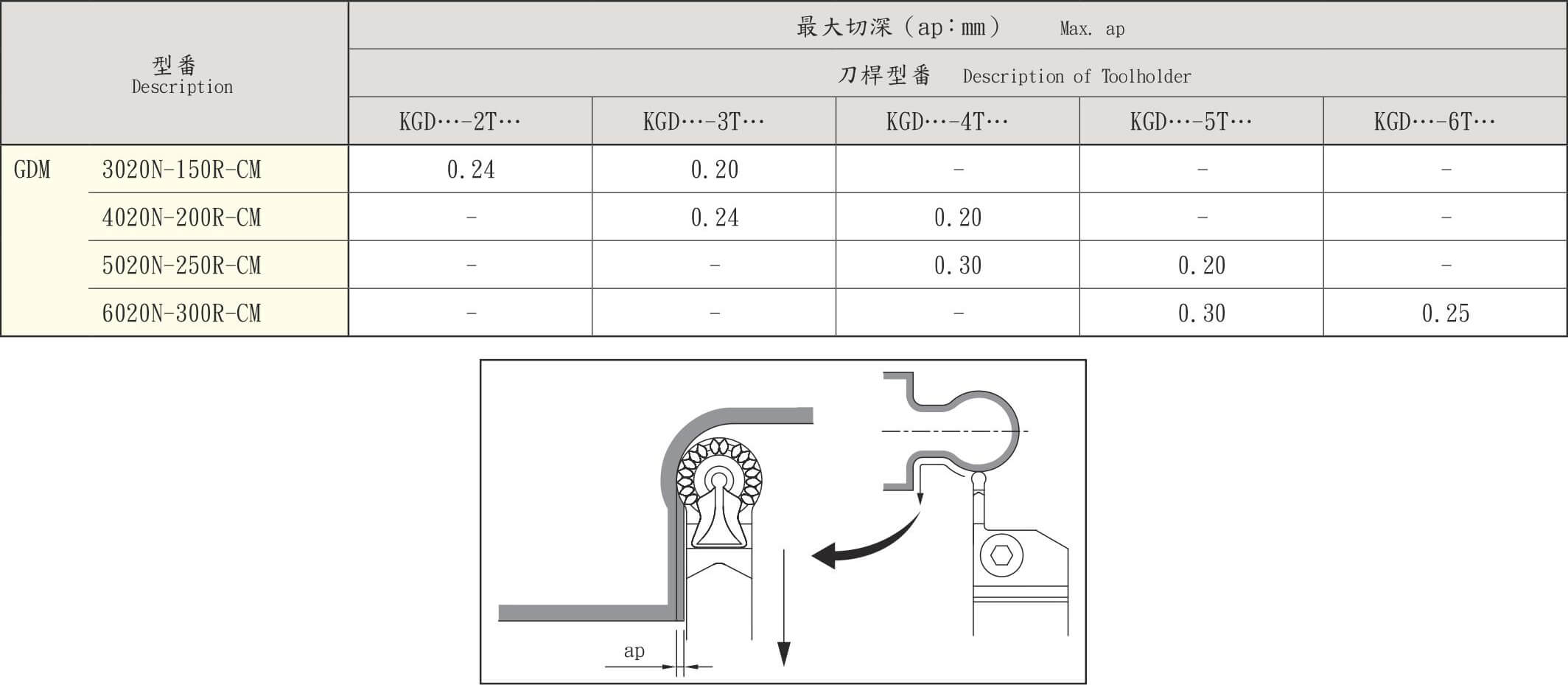

CM斷屑槽[加工時最大切深]最大切深(ap)的推薦

CM chip-breaker [ about max. a.p. for pulling up ] Recommended ap for pulling up.

分離型刀桿型番和旋盤安裝方式指引 Descriptions of separate type toolholder and indication of setting up to machine.

刀桿和刀板安裝時不要有縫隙。 No gap between blade and tool block.

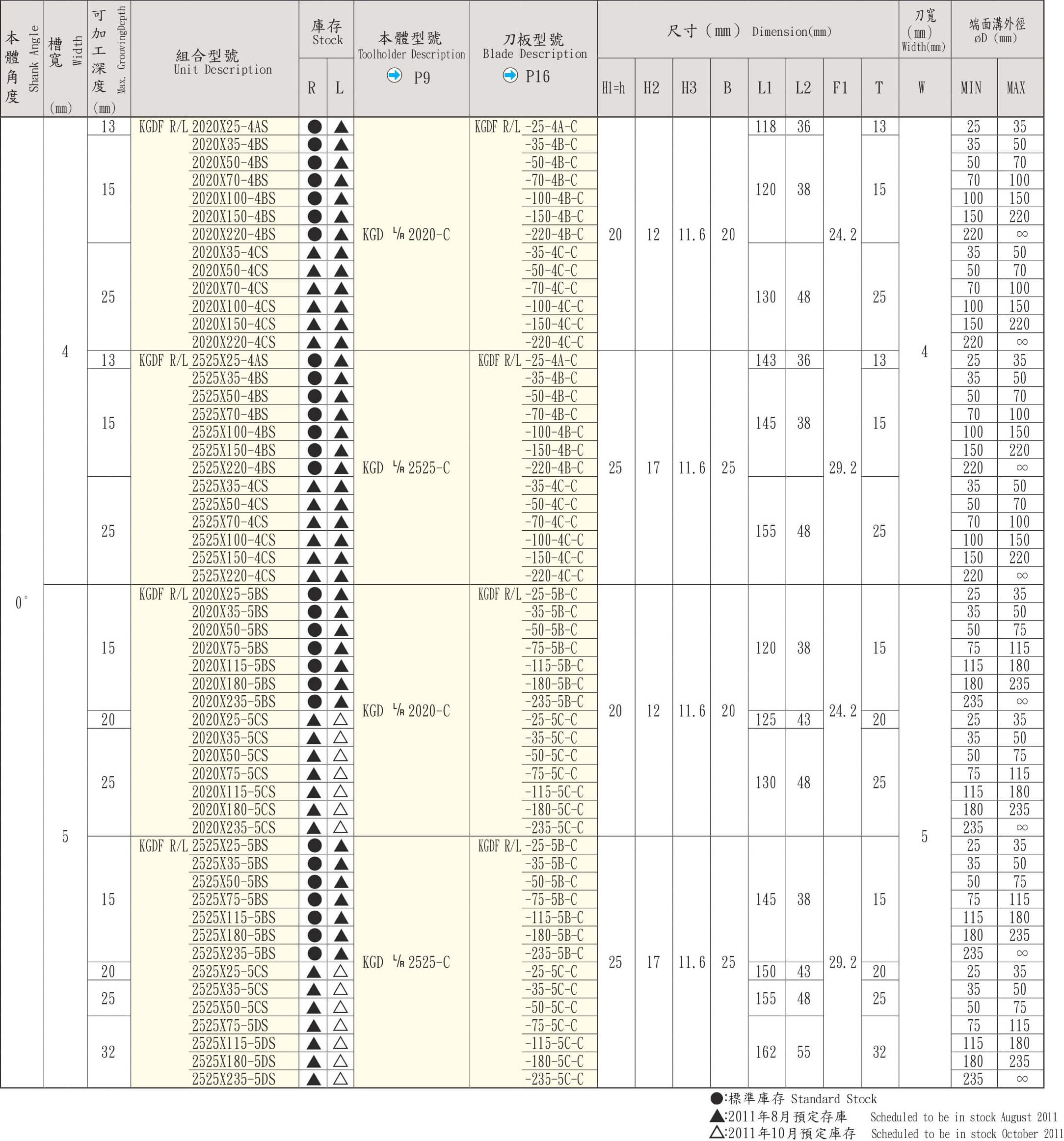

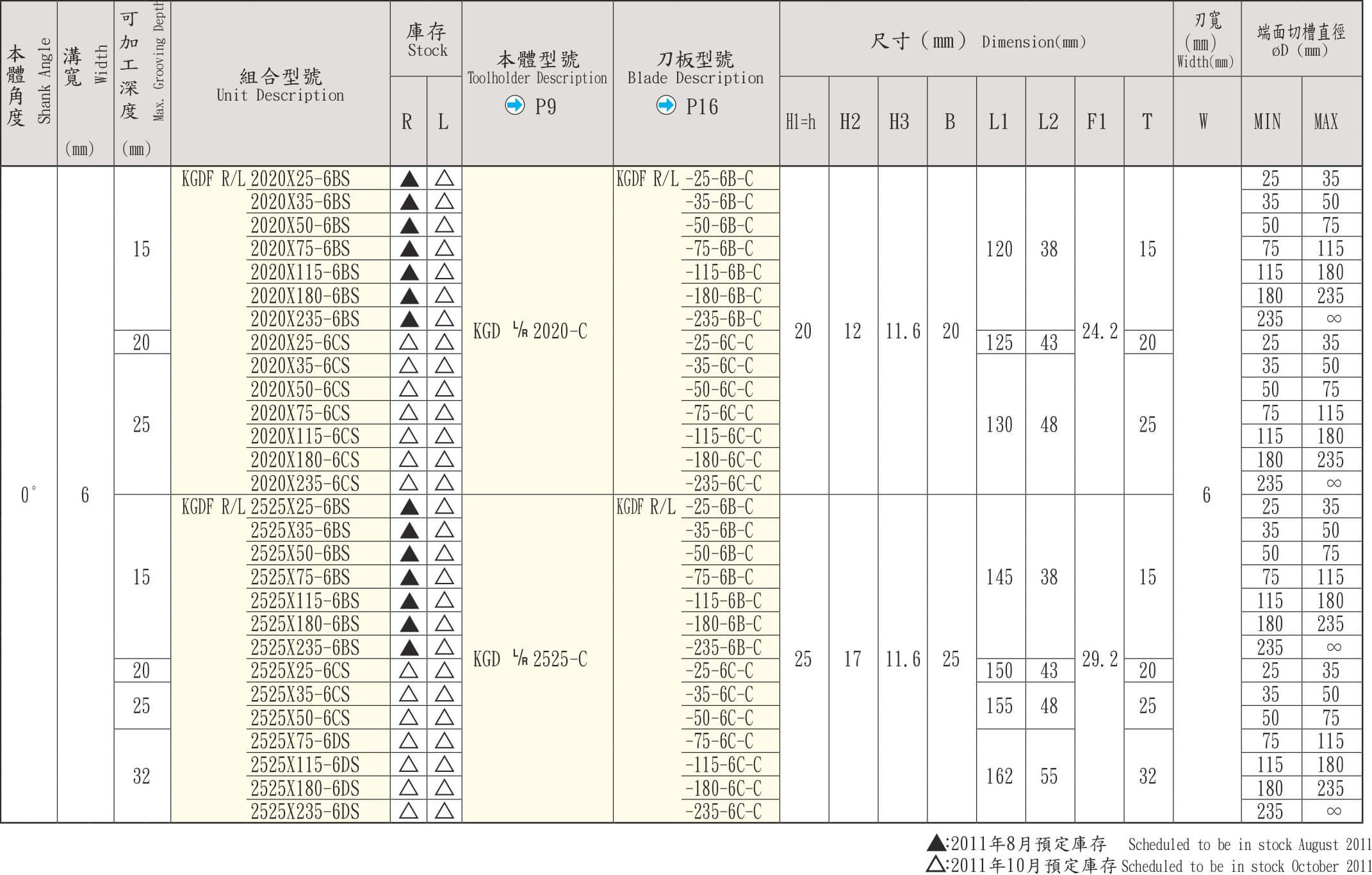

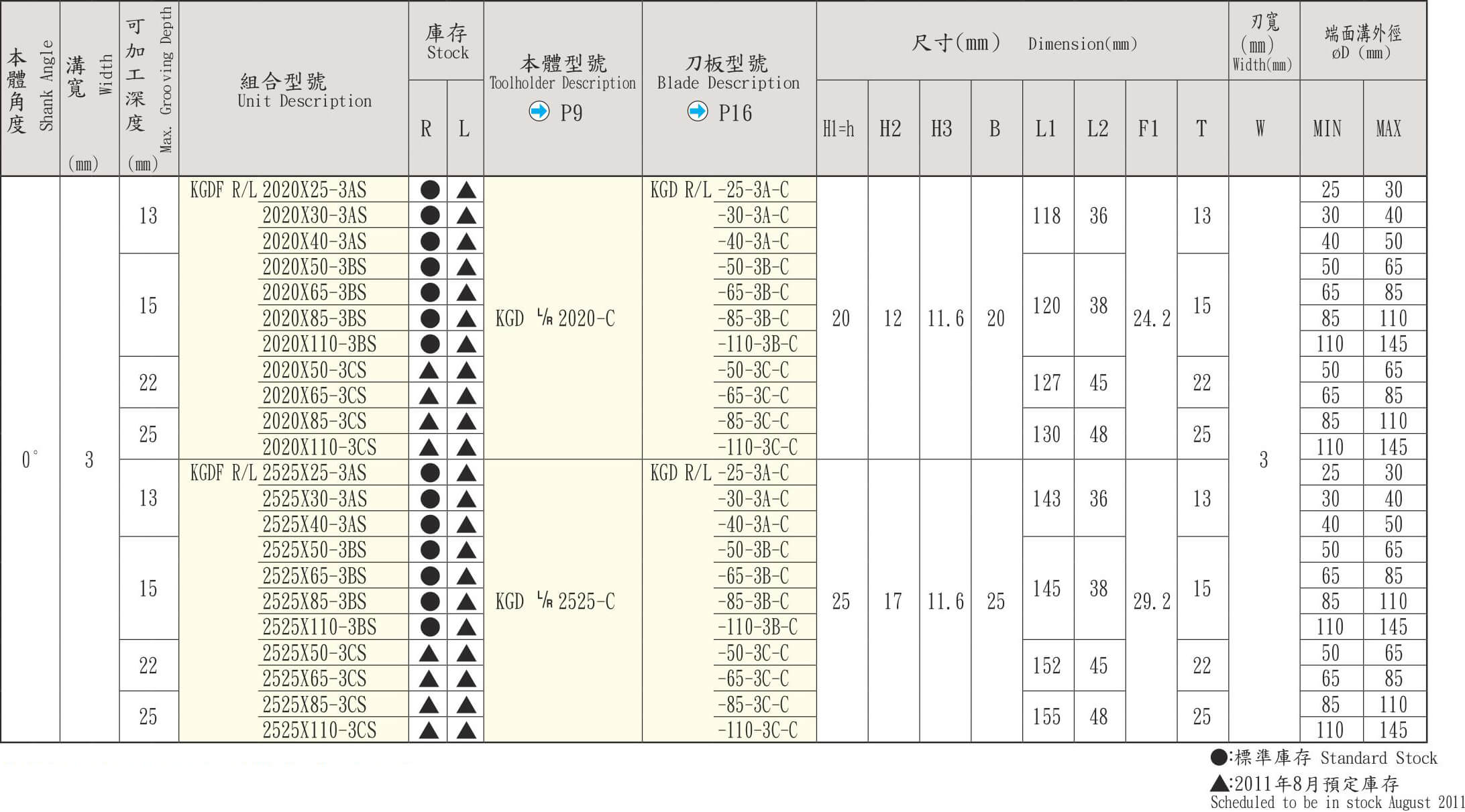

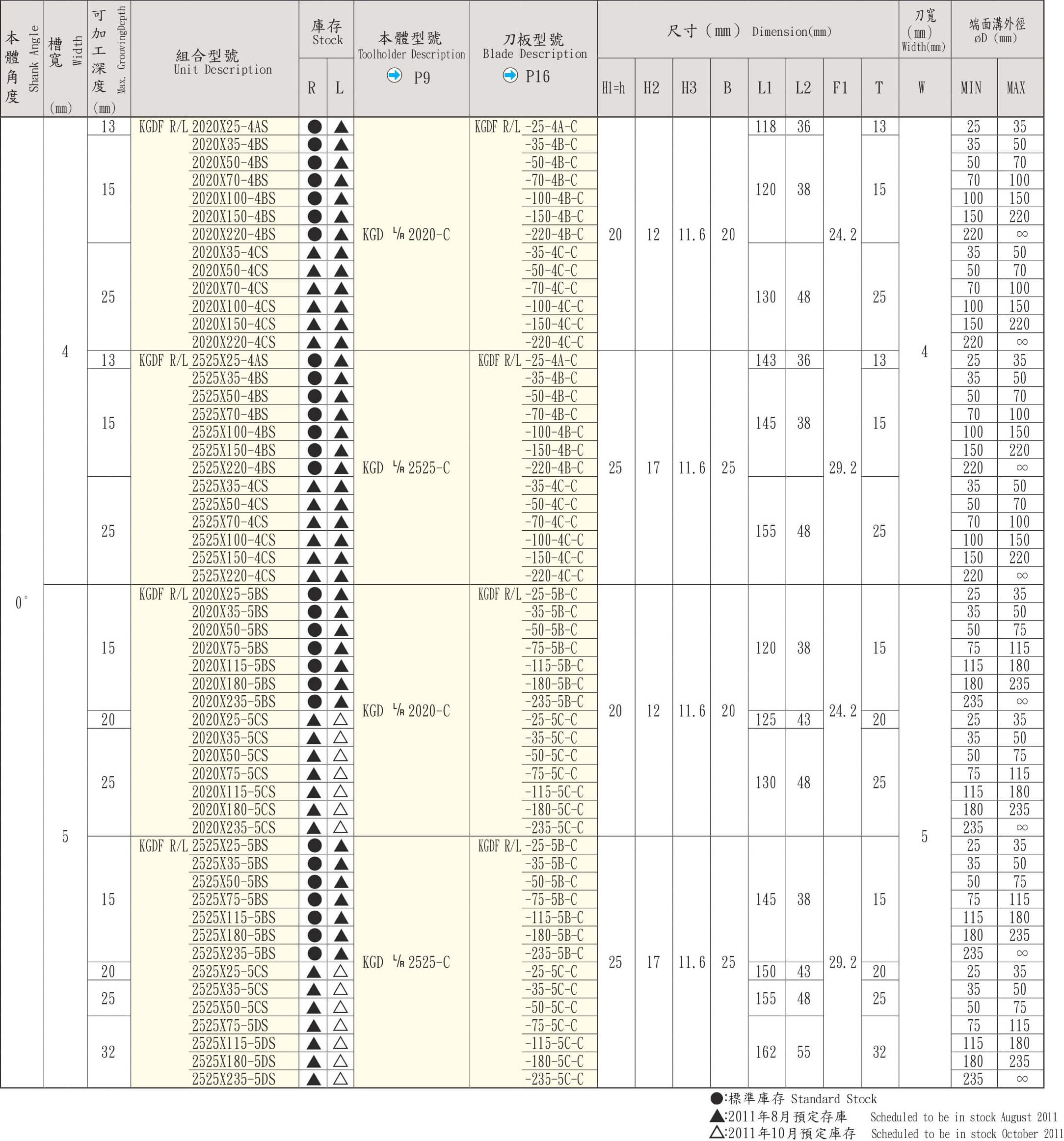

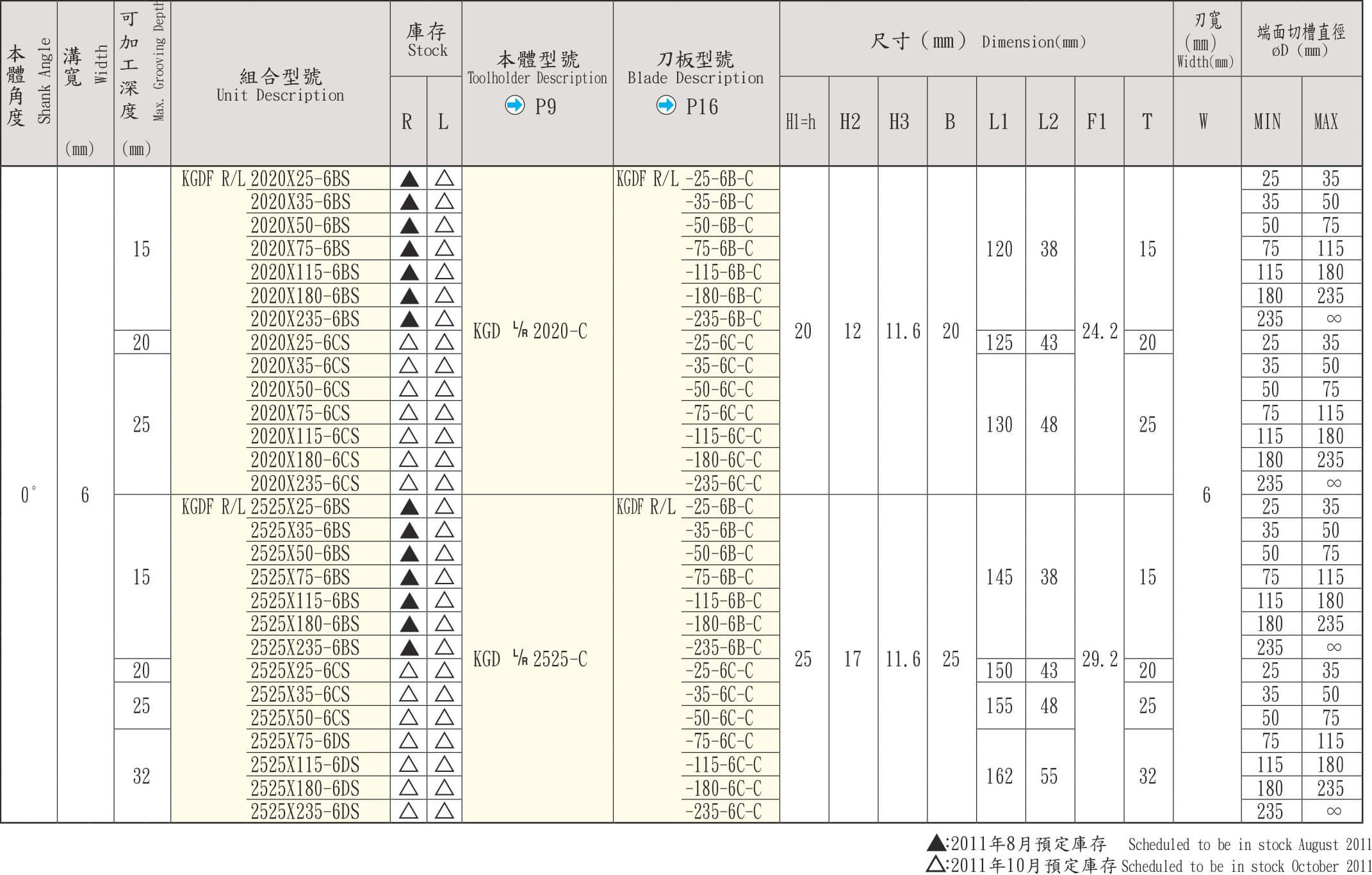

KGDF型

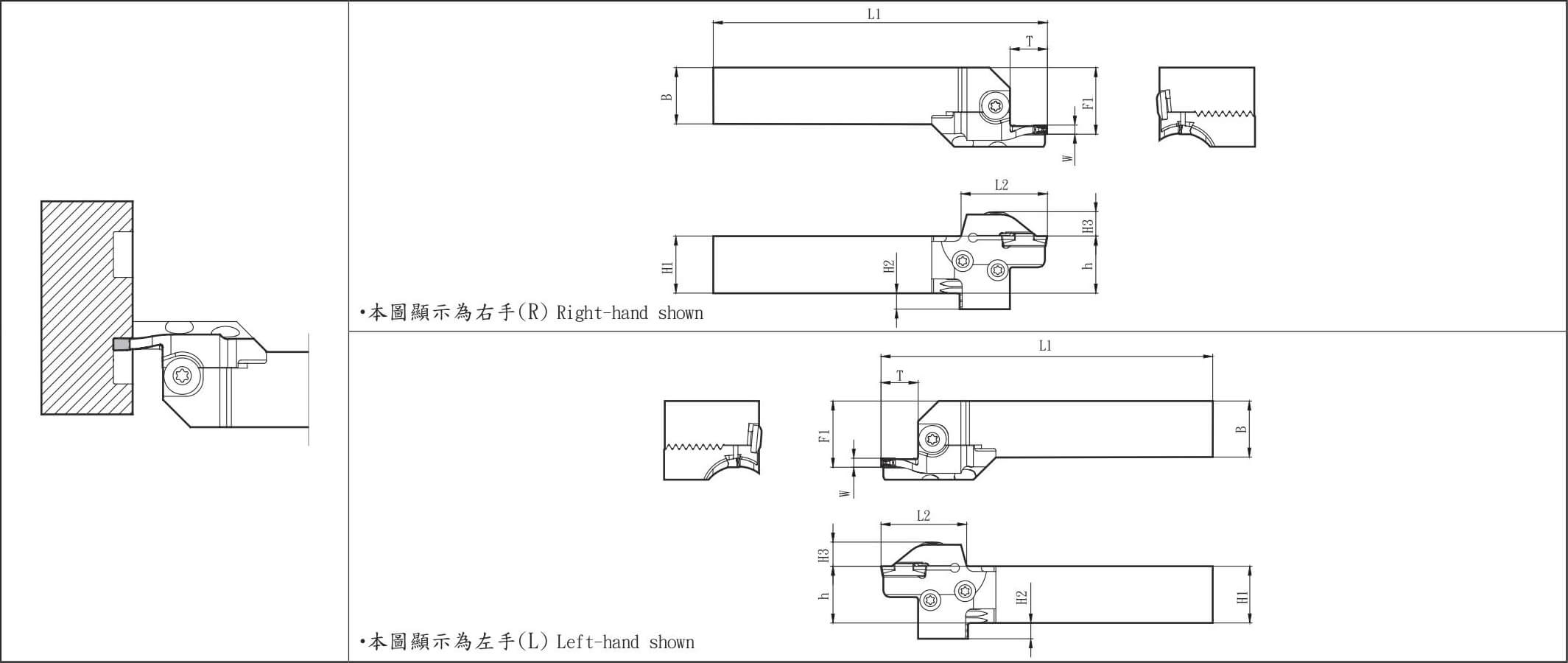

KGDF型 端面切槽工具

KGDF Face grooving tool

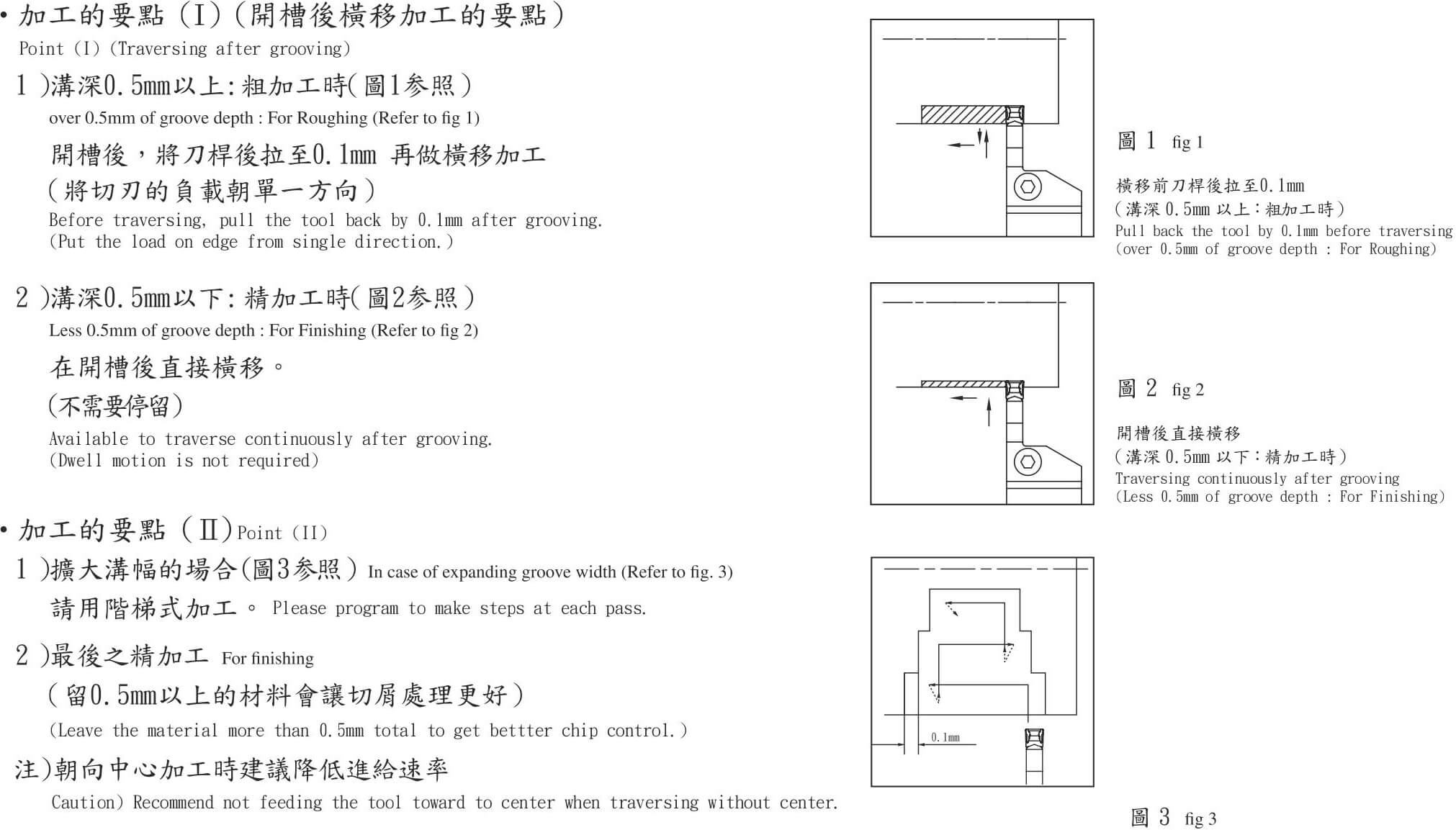

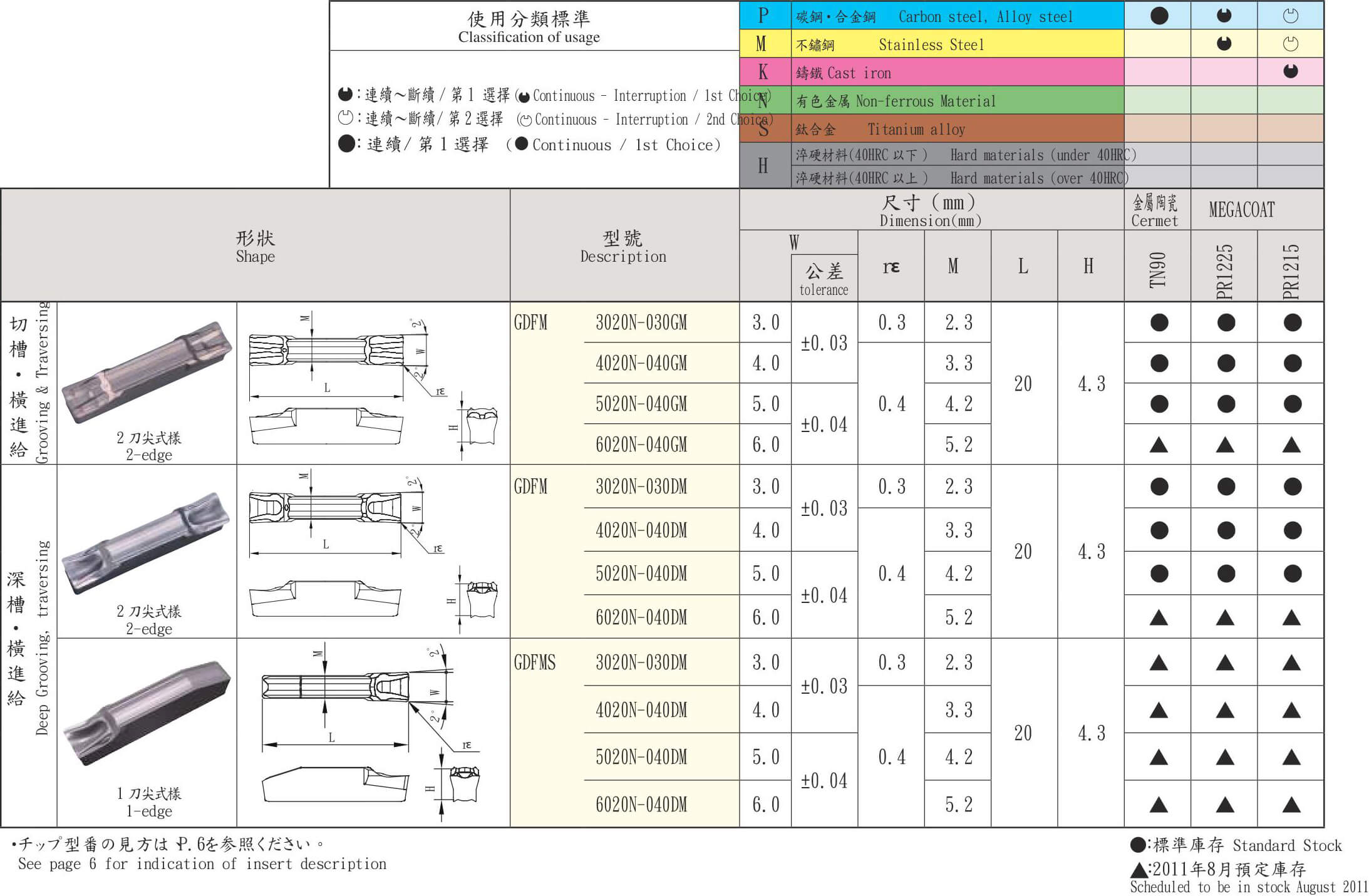

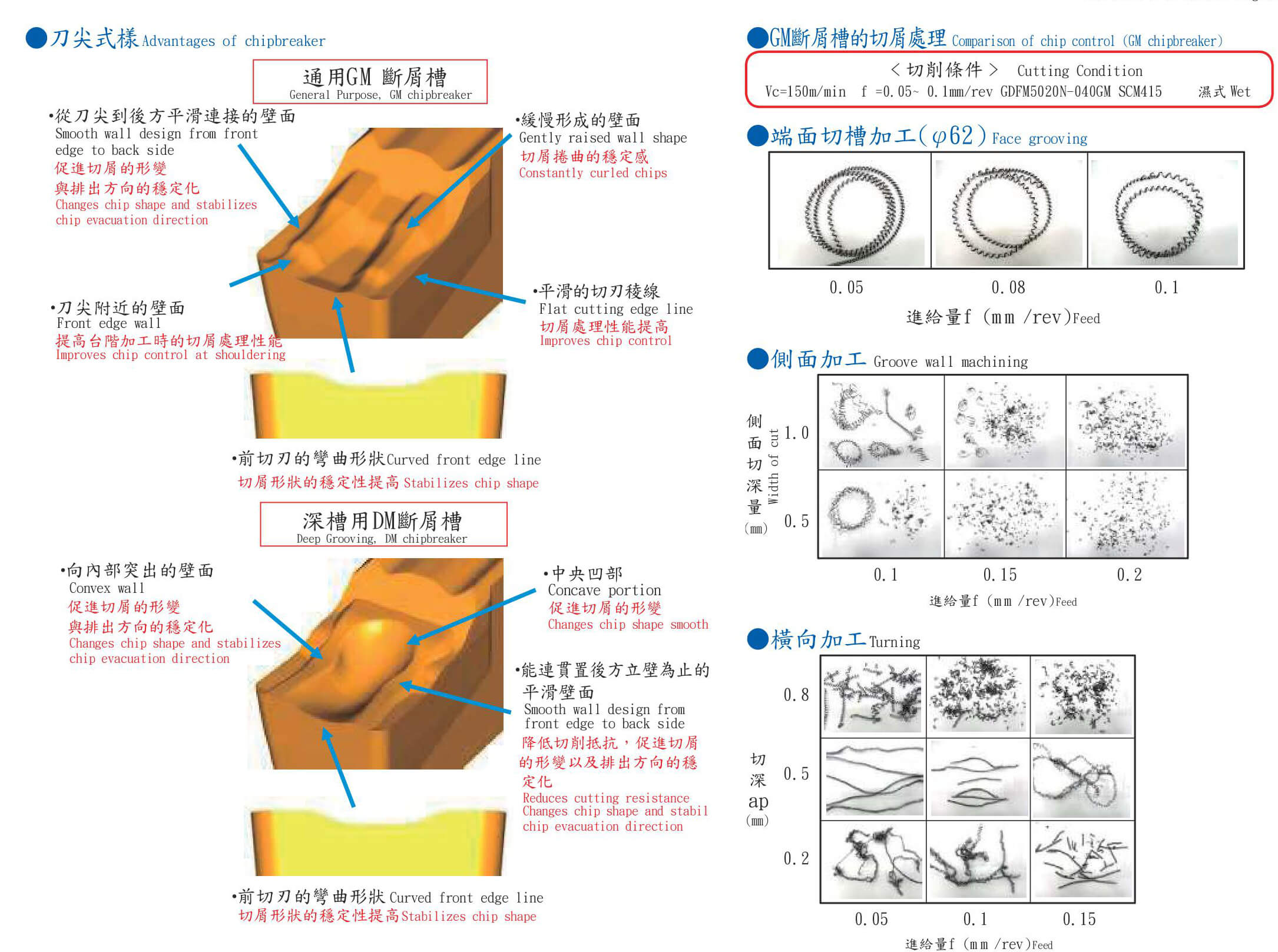

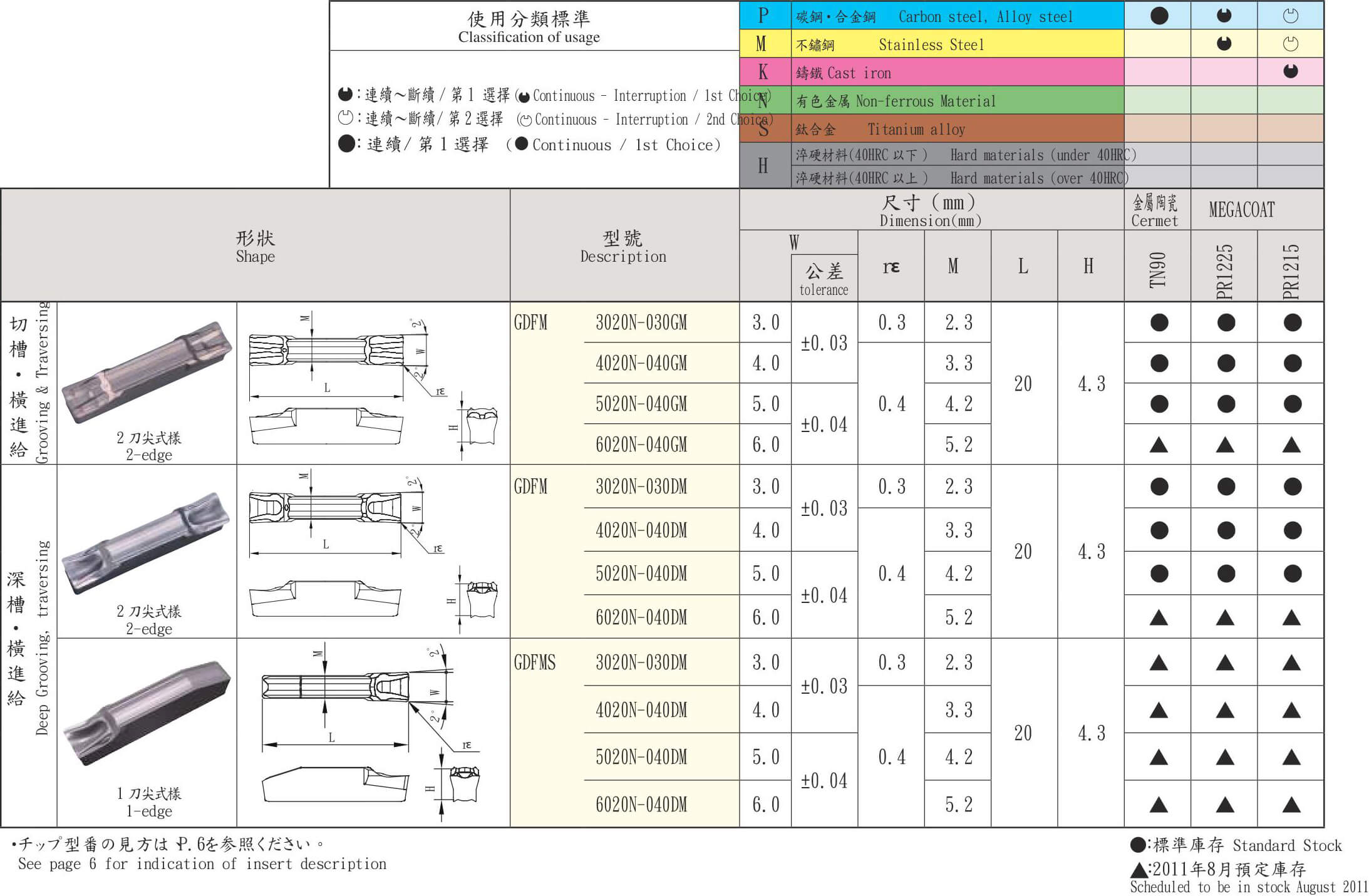

GDFM/GDFMS型

KGDF型

KGDF type

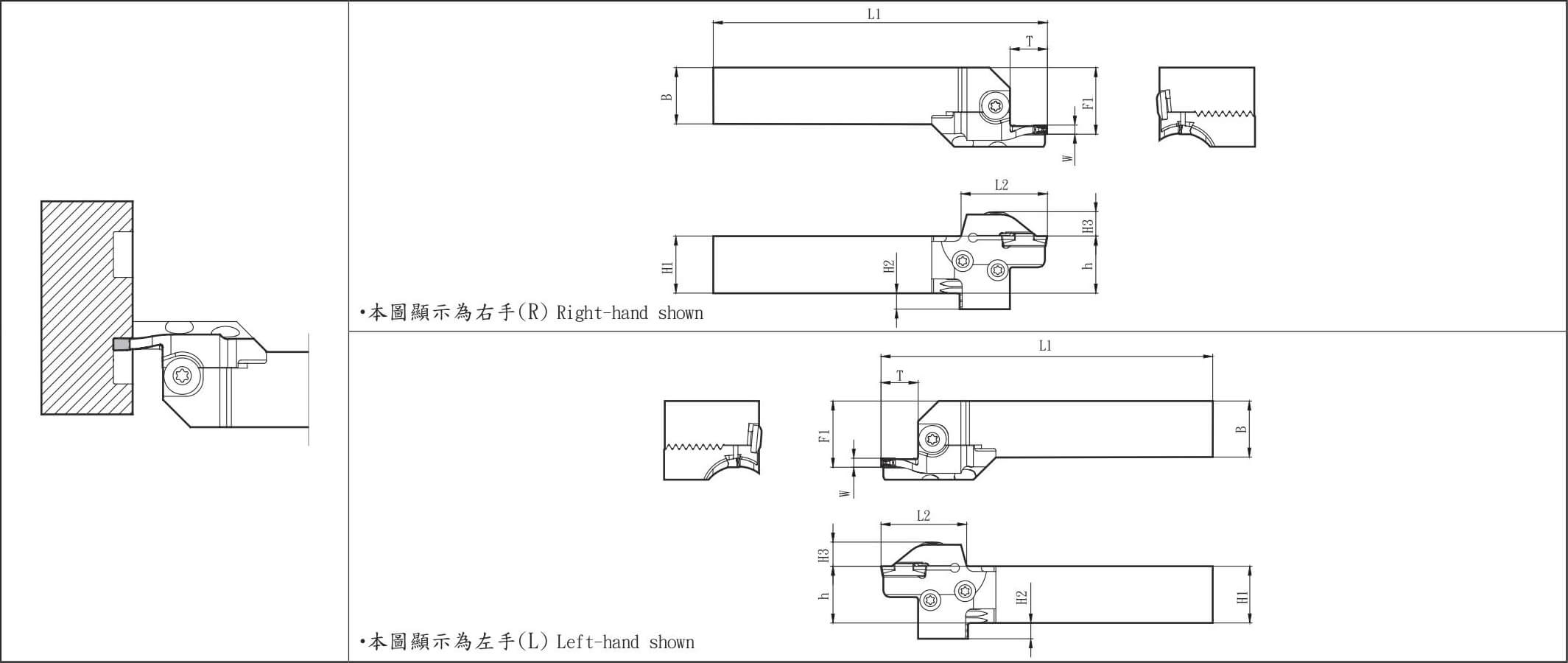

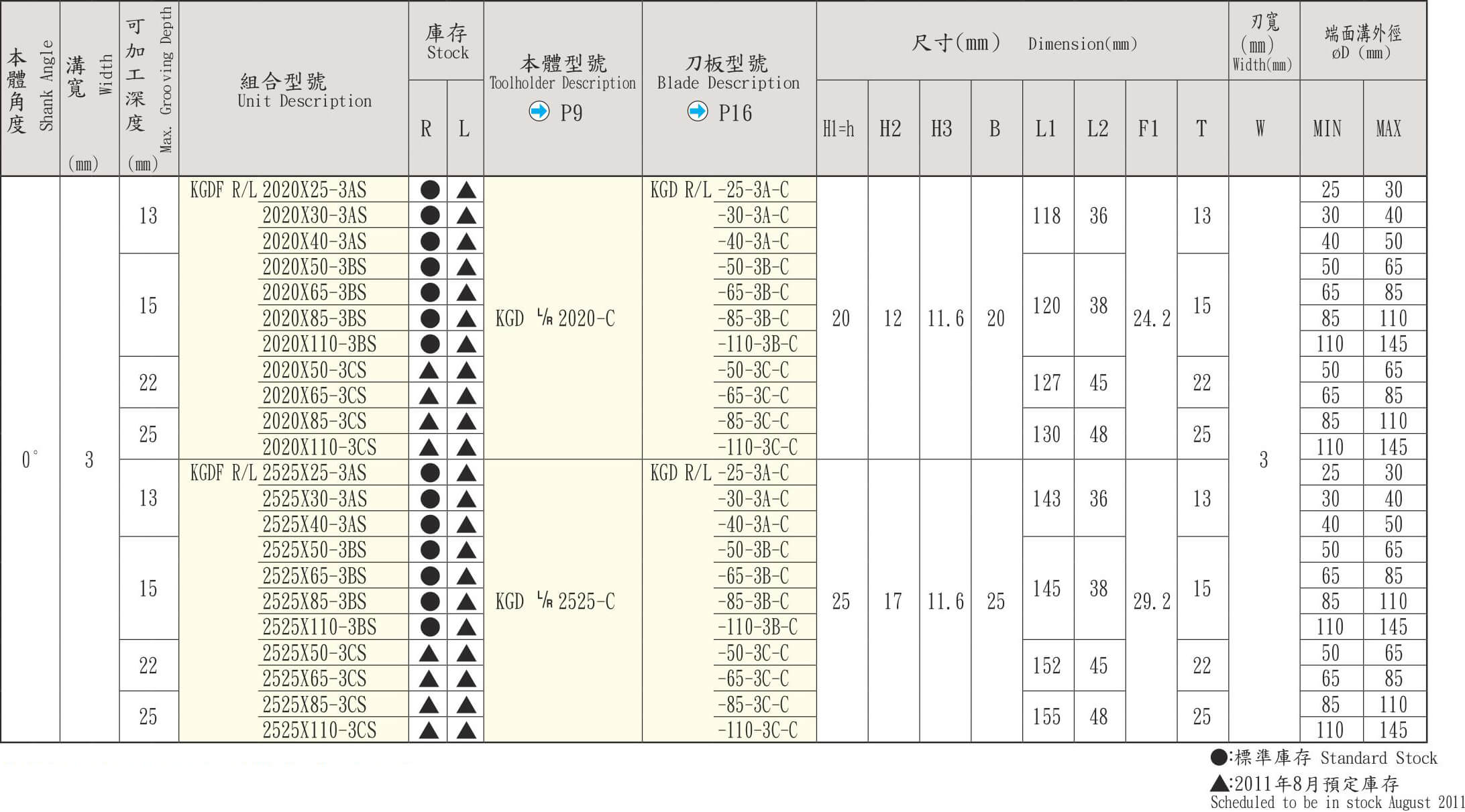

刀桿尺寸 Toolholder dimensions

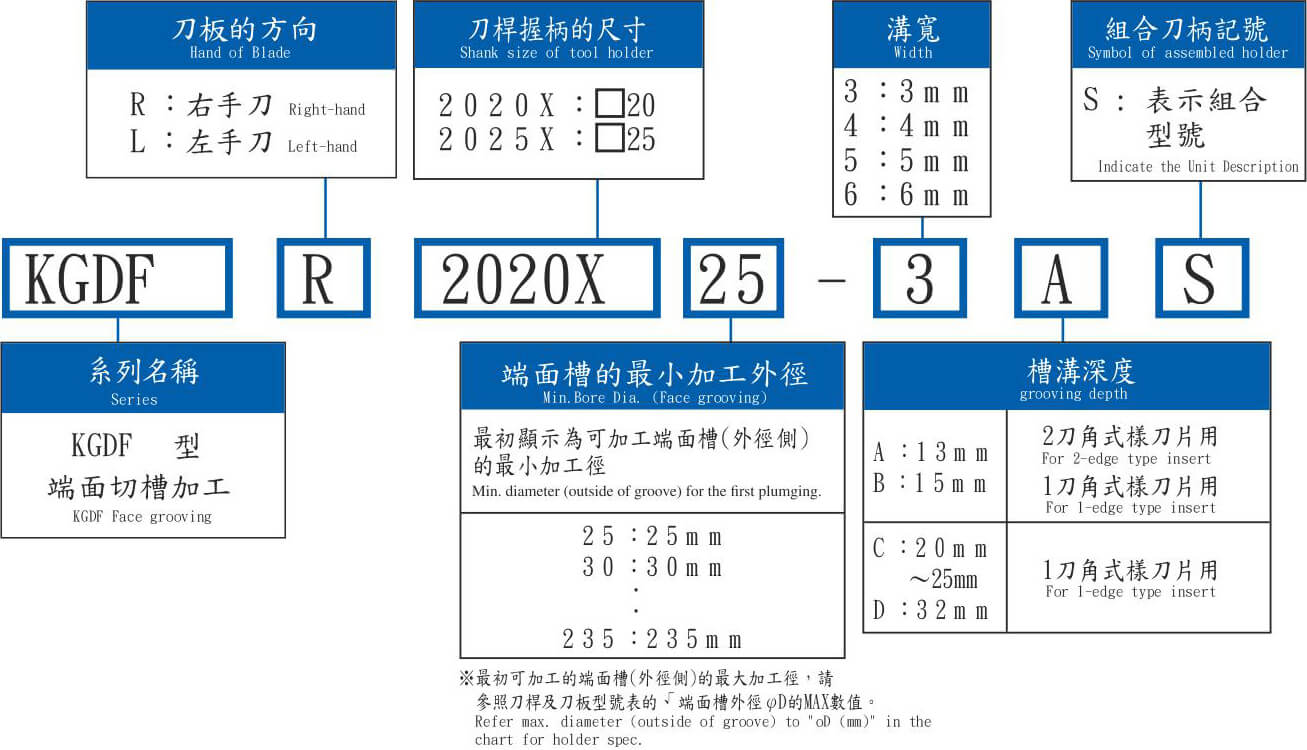

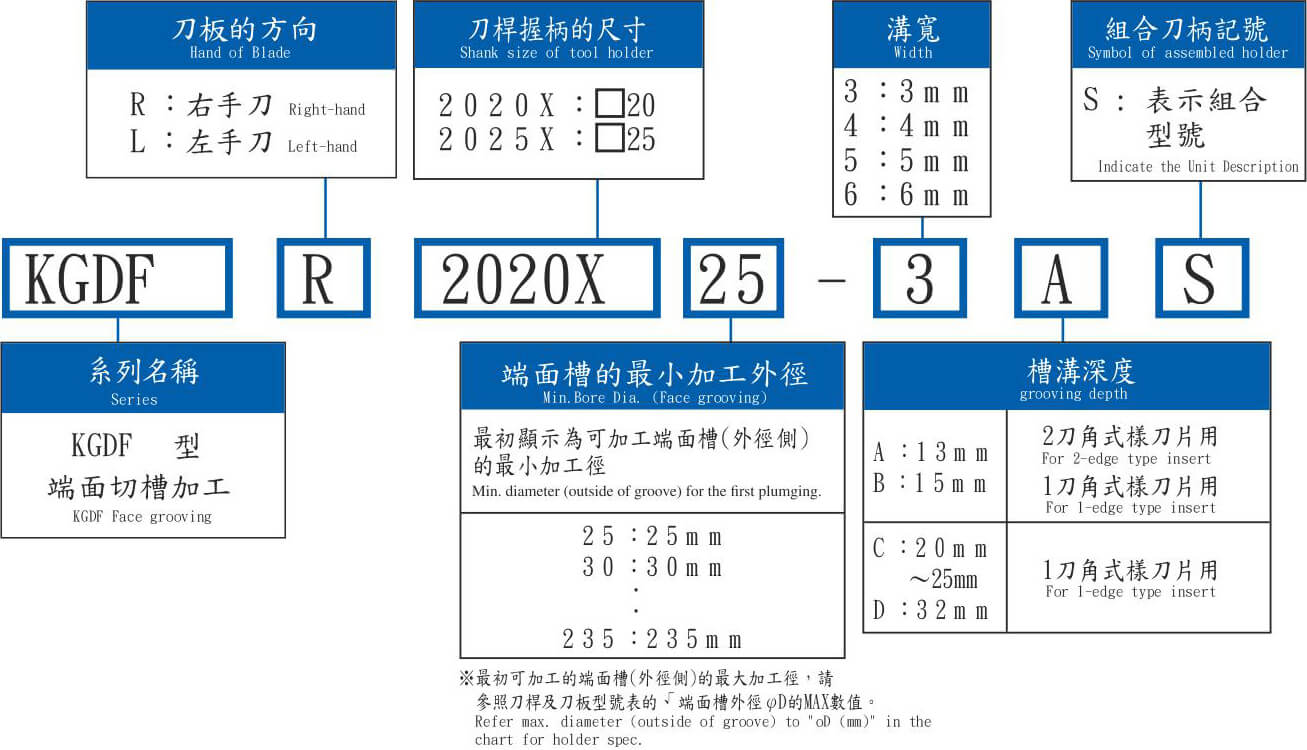

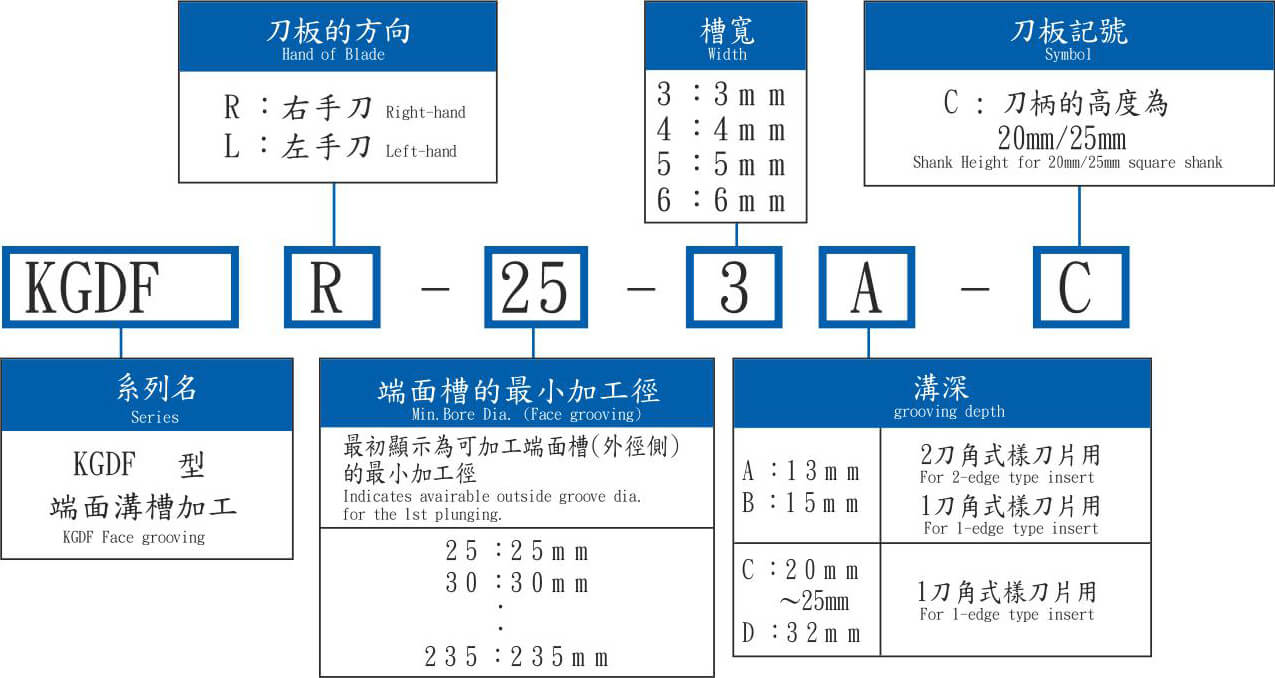

KGDF型刀桿組合型號的表示方式 Indication of KGDF unit description

KGDF型刀桿組合型號的表示方式 Indication of KGDF unit description

刀桿尺寸 Toolholder dimensions

刀桿尺寸 Toolholder dimensions

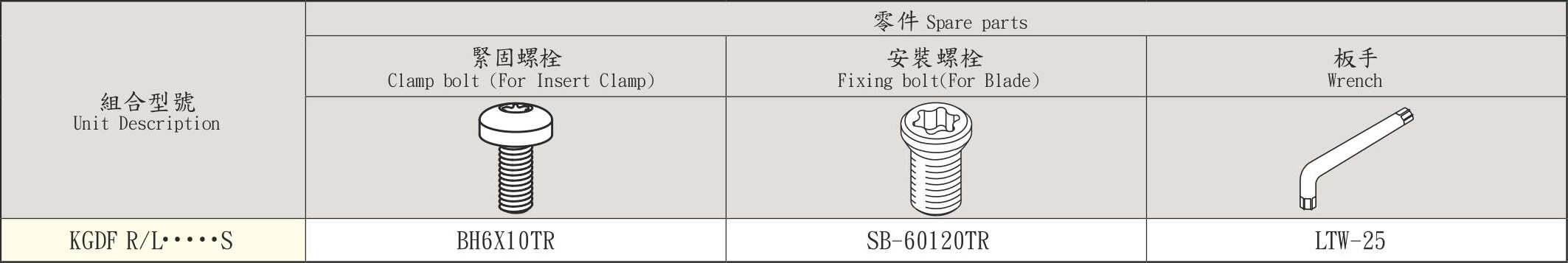

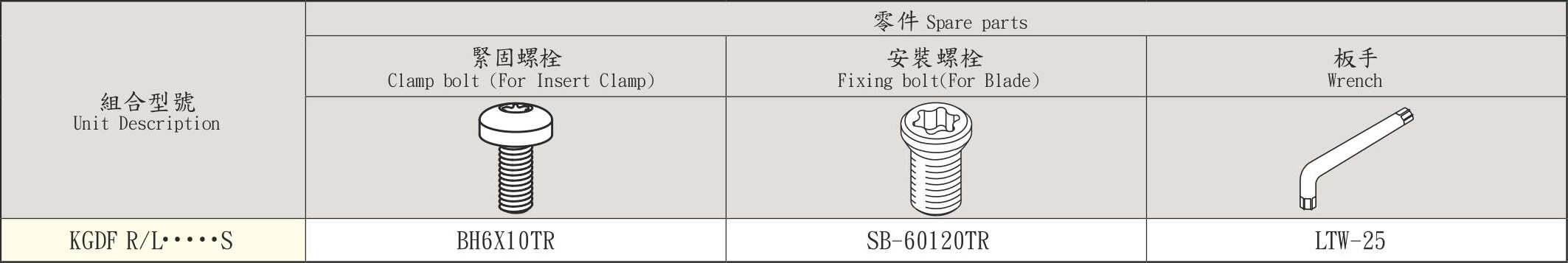

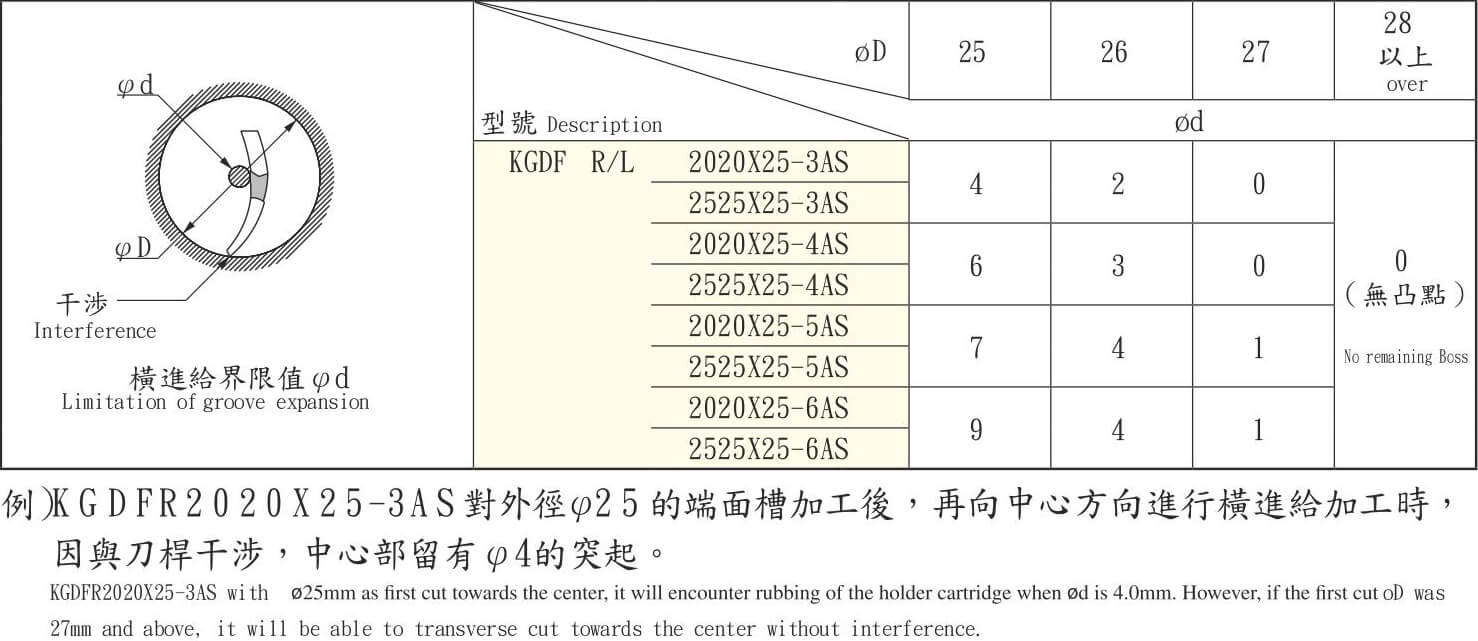

零件 Spare parts

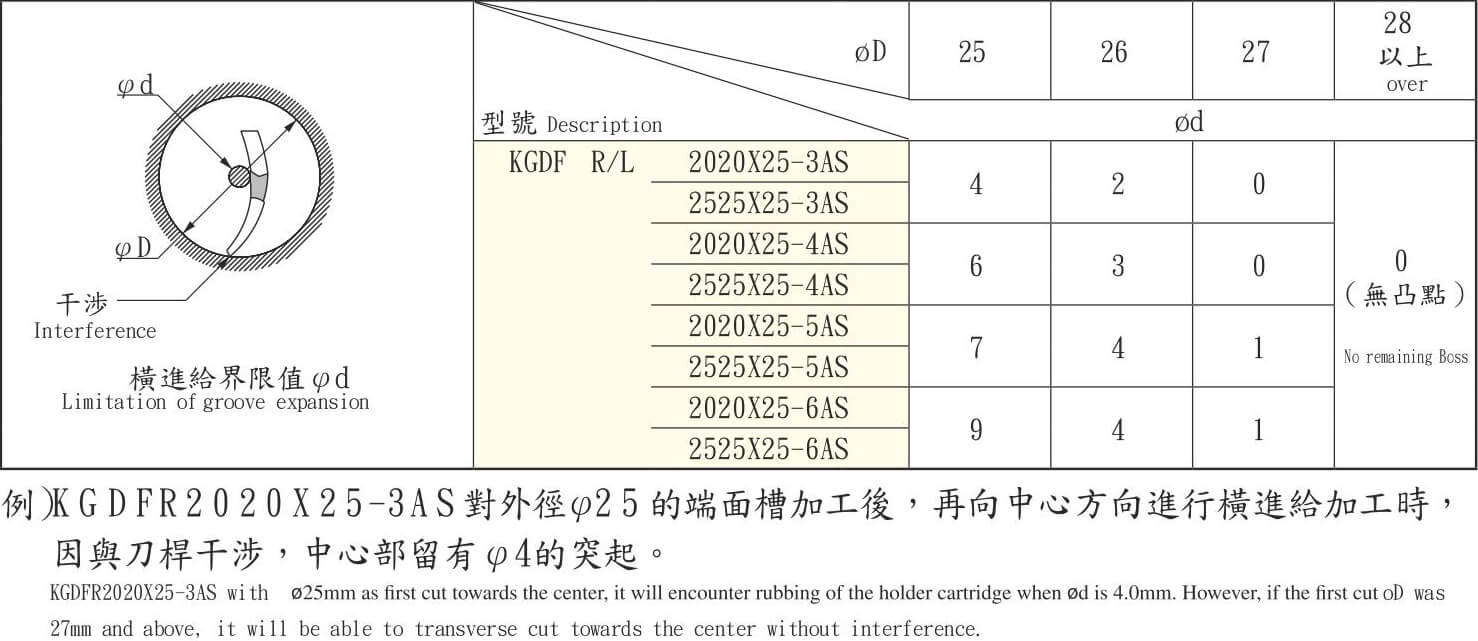

小徑加工至中心時因为刀桿與之干涉所以受限。此外,外徑可擴大至無限大進行槽的擴大加工。 Please be aware of the limit diameter when expanding the groove to the center. There is no limit diameter to expand the grove outside,

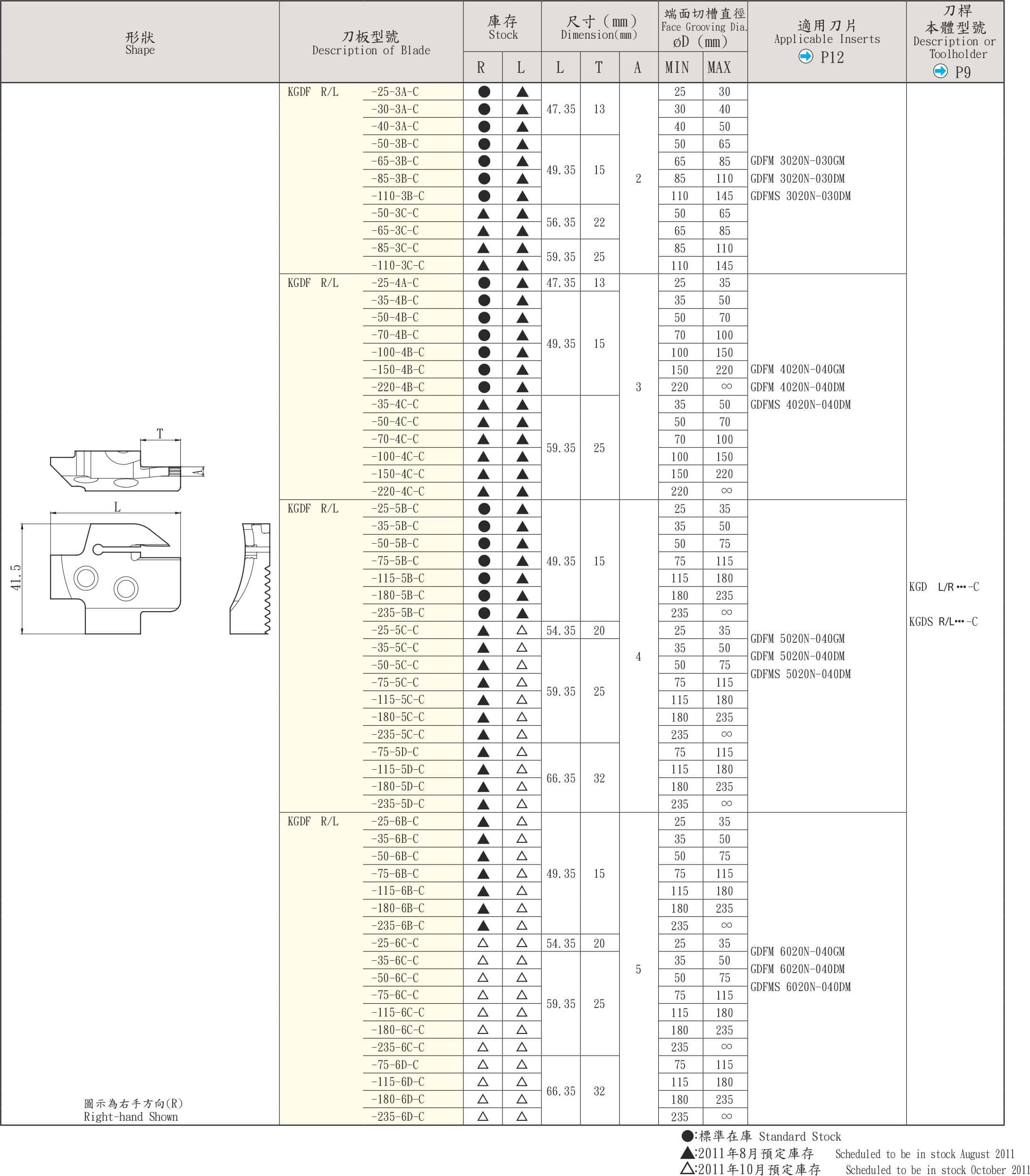

刀桿尺寸 Blade dimensions

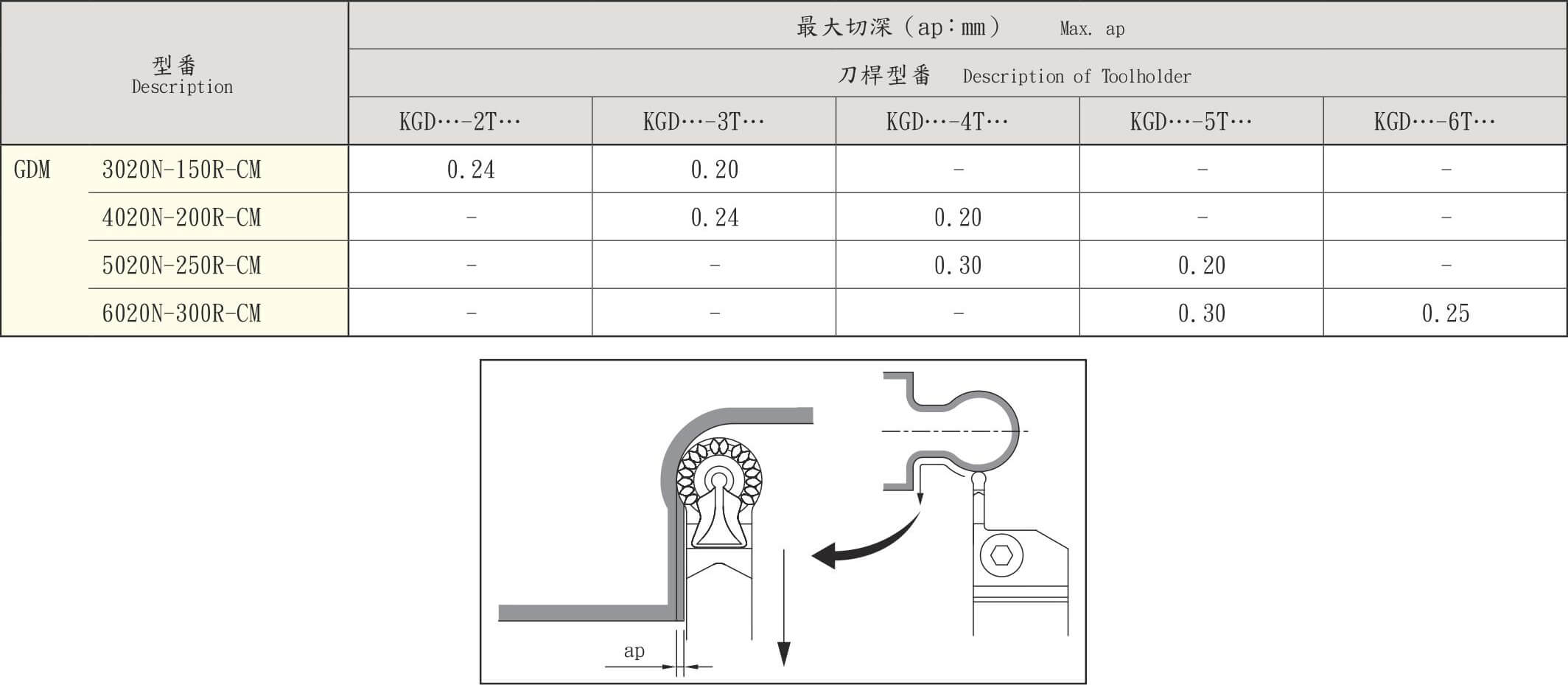

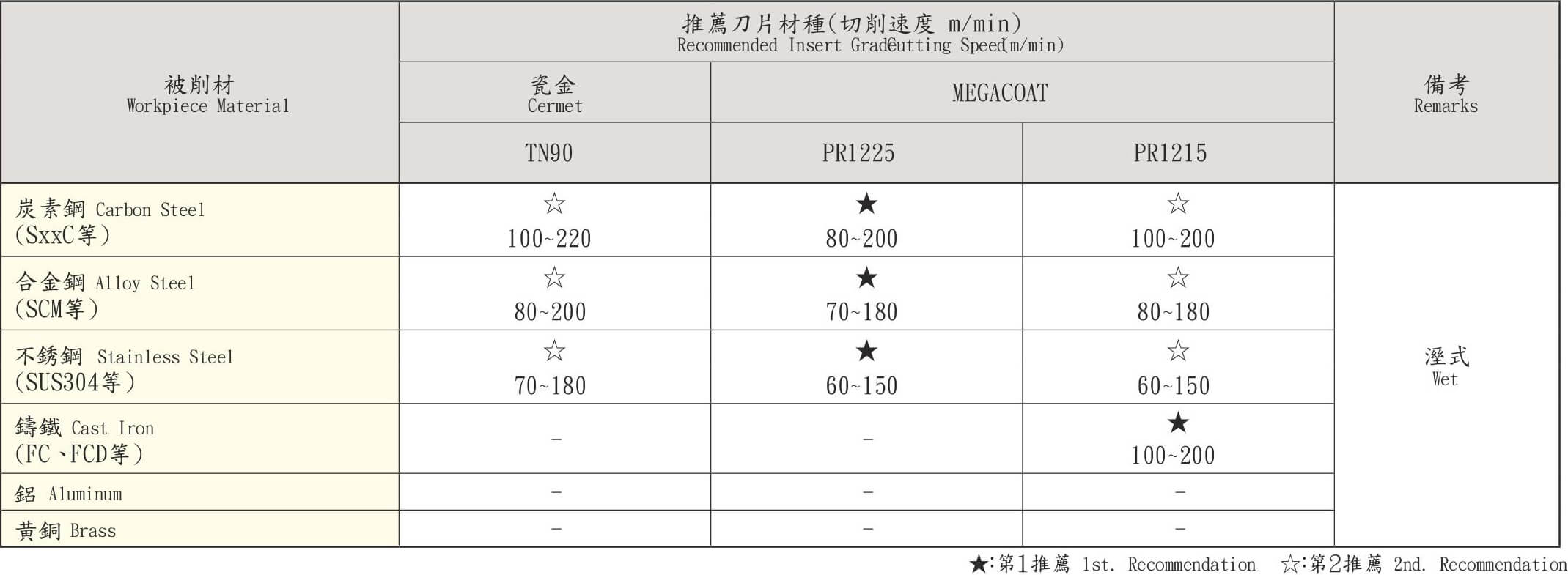

推薦切削條件(端面槽溝)

推薦切削條件(端面槽溝)

Recommended Cutting Conditions (Face grooving)

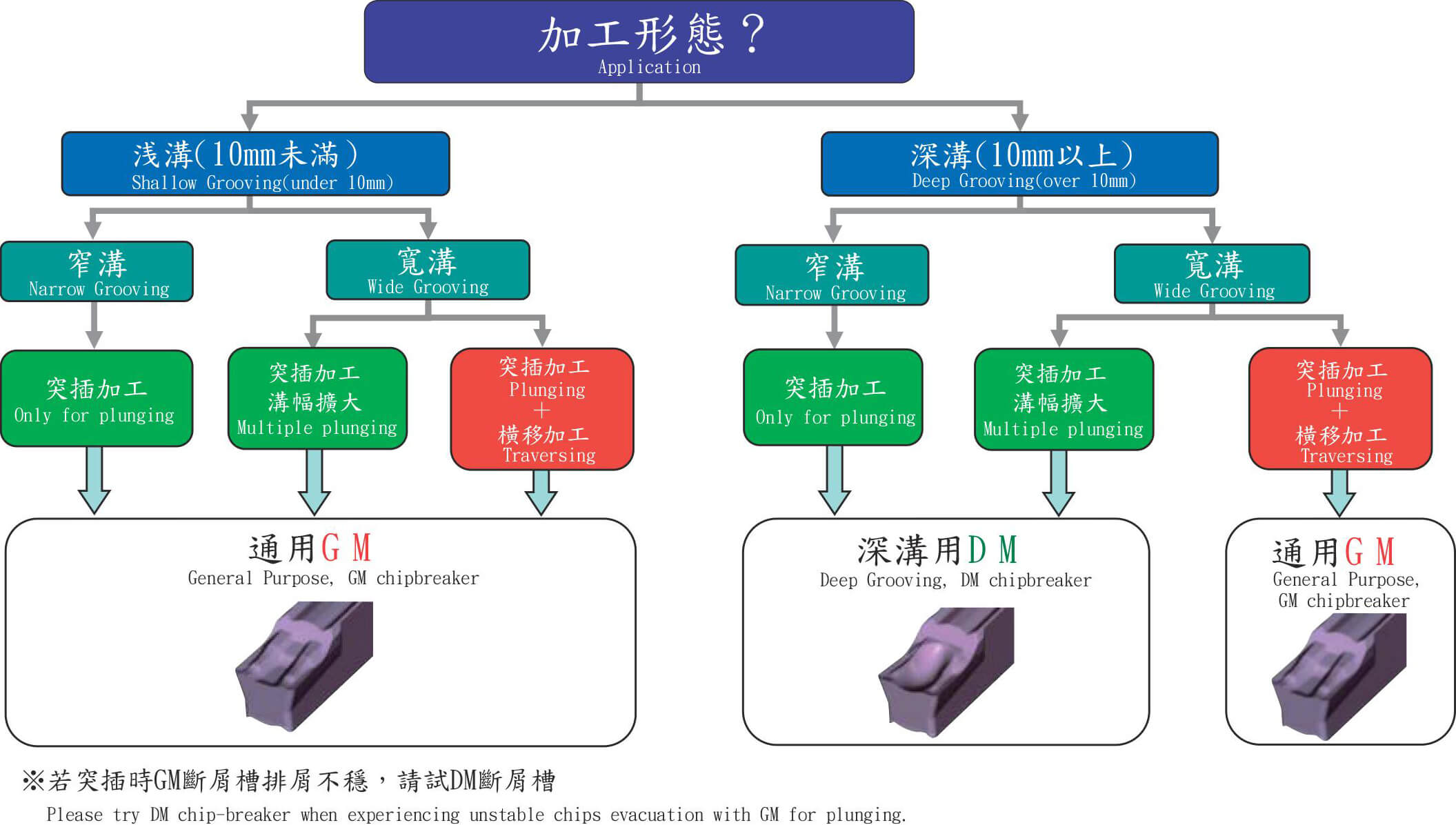

斷屑槽選擇基準(端面溝)Chipbreaker Selection(Face grooving)

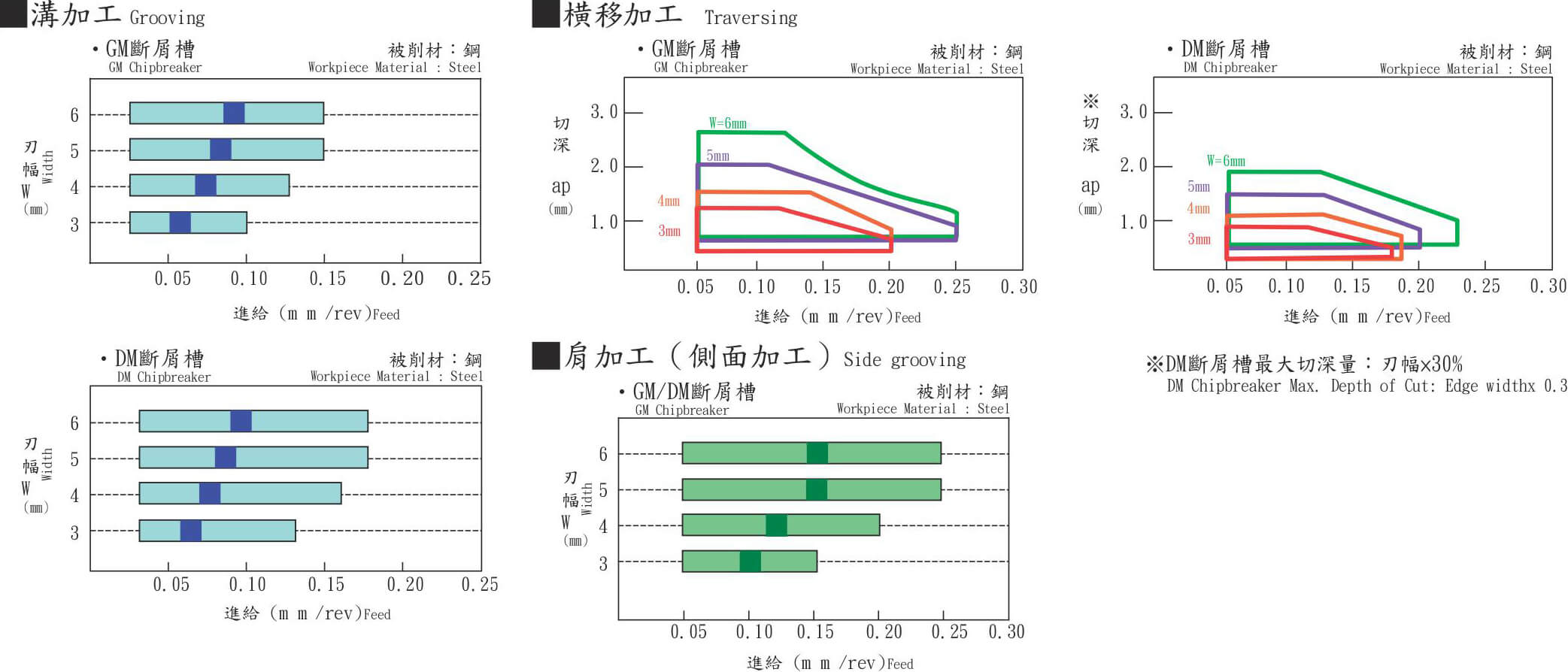

推薦切削條件(進給、切深)Recommended Cutting Conditions (f, ap)

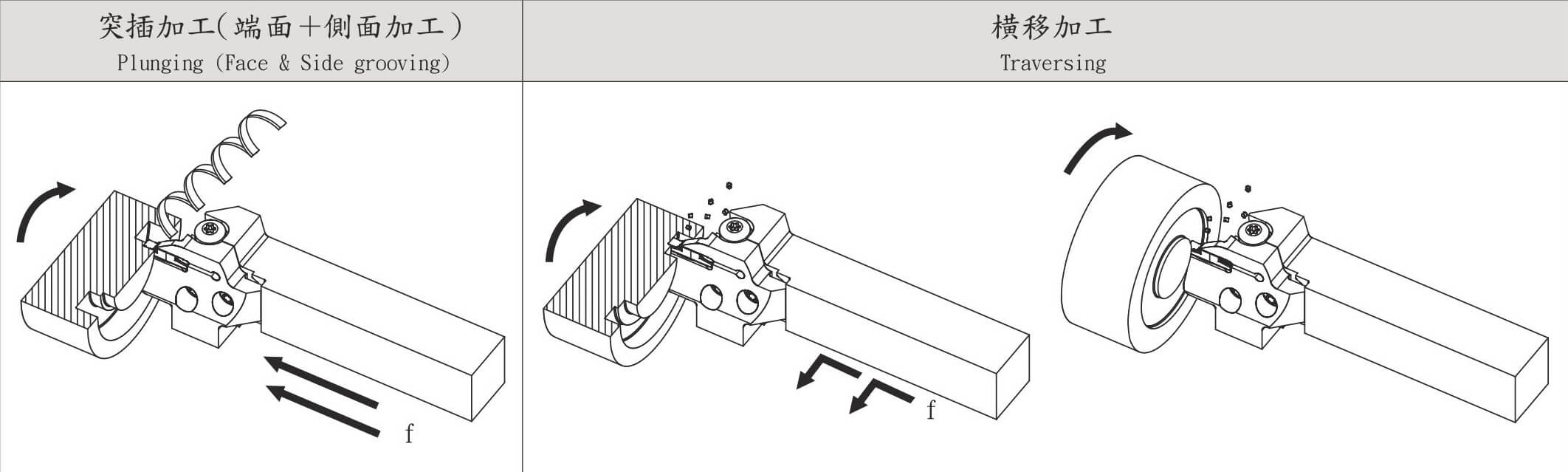

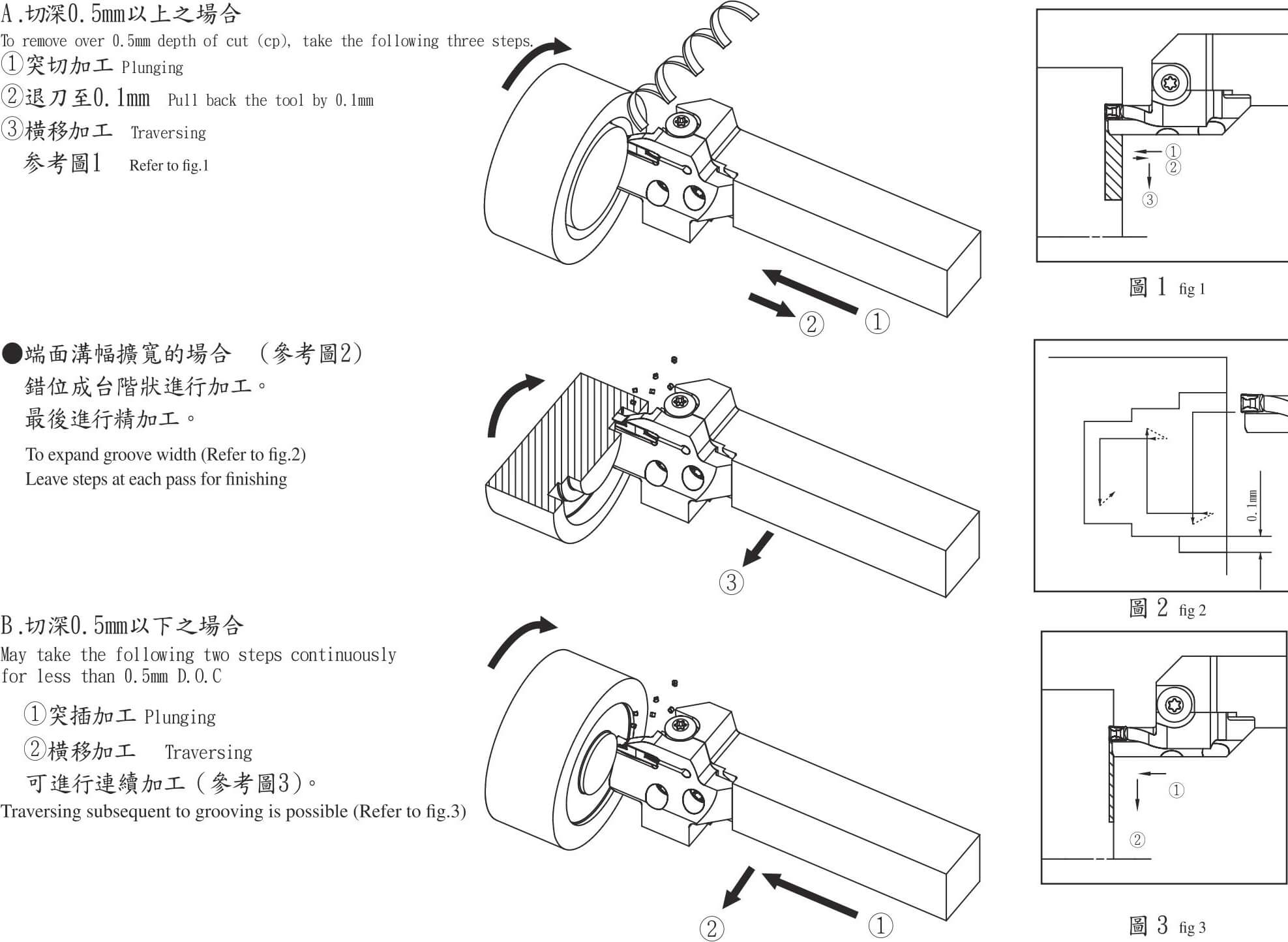

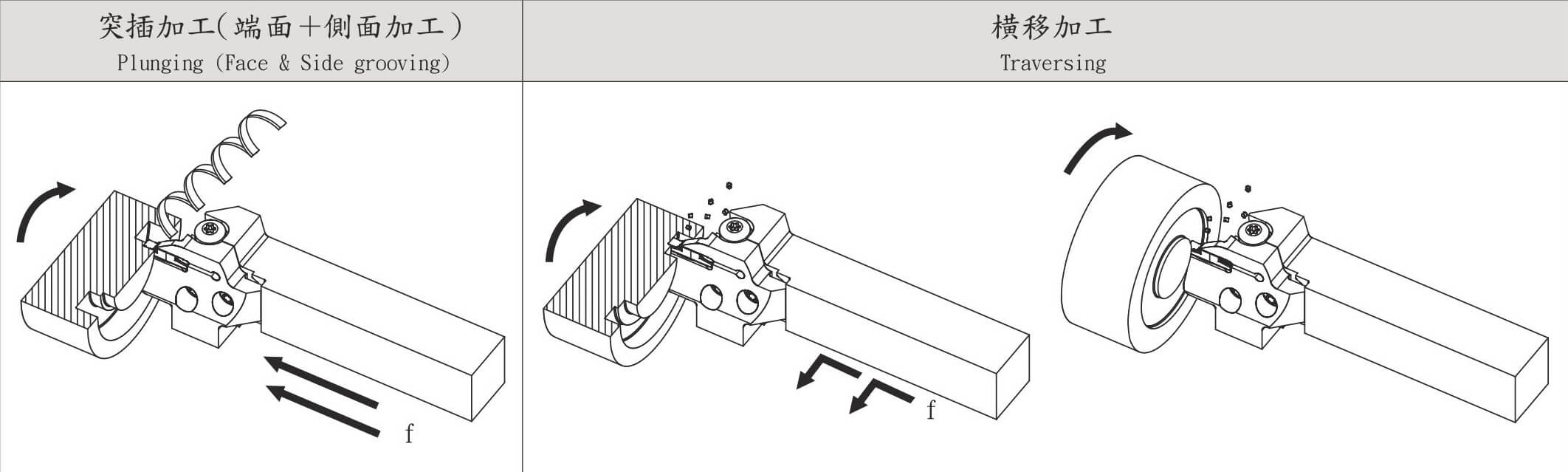

端面槽溝加工的重點 Points for face Brixing

1)刀桿選擇Tool holder Selection

端面槽溝加工,除了溝深與寬度外 亦須確認端面溝最大及最小外徑。

Check available in and max dia as well as width and depth

2) 切削條件(進給:f)的設定Feed rate

進行鋼材等端面加工 設定適當的進給保持切屑連續排出。

Set proper feed rate to create continuous chips for face grooving on steel

3)槽宽擴大加工Expand groove width (Plunging, Traversing)

要從外側向中心加工 切屑排出才會良好。

Recommend traversing from outside to inside to get better chips evacuation

橫移加工時需注意的點Points for traversing

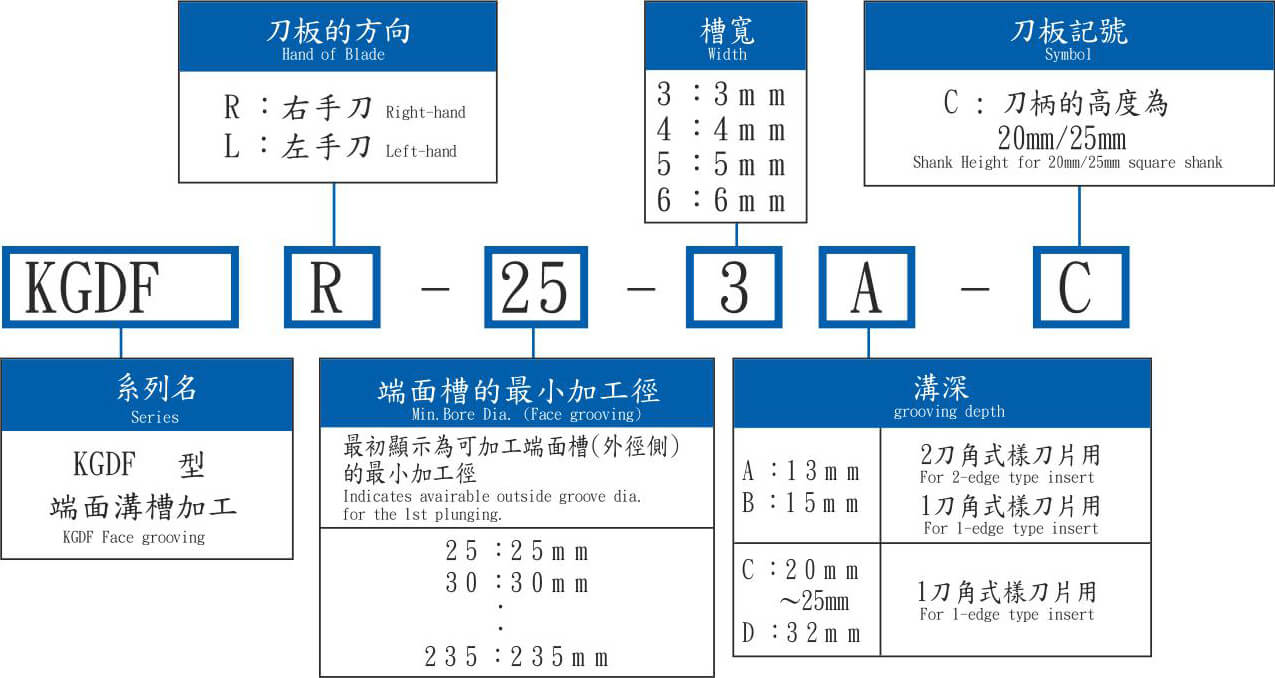

KGDF型刀桿組合型號的表示方式 Indication of KGDF unit description

KGDF型刀桿組合型號的表示方式 Indication of KGDF unit description