產品介紹

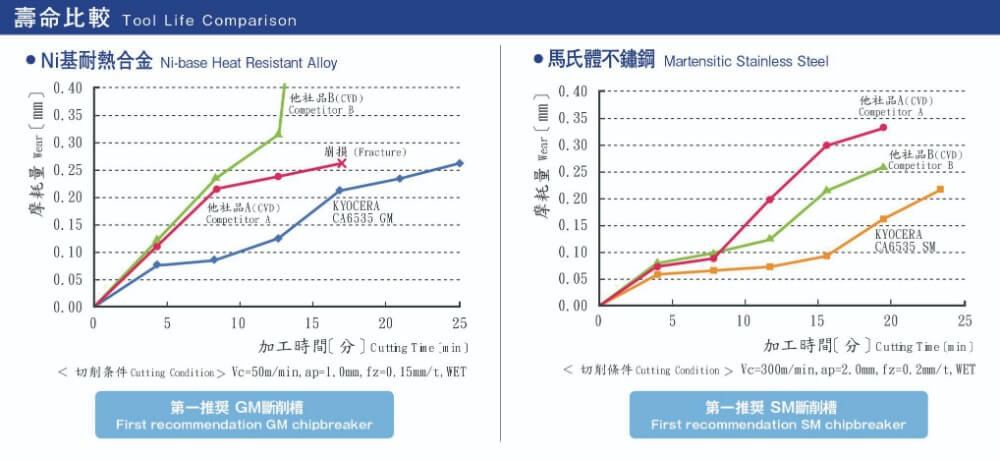

2種材種對應耐熱合金・難切削材 實現長壽命加工

2 types of grades realizes tool life extension at machining of heat resistant alloy and difficult-to-cut materials

CA6535

(CVD)Ni基耐熱合金、馬氏體不鏽鋼用

For Ni-base heat resistant alloy and martensitic stainless steel

|

PR1535

(PVD)鈦合金、析出硬化型不鏽鋼用

For titanium alloy and precipitation hardened stainless steel

|

對應各種不同被削材!

Suitable for variety of workpiece materials

抑制突發之崩損、實現安定加工 適合高能率加工

Stable cutting by preventing sudden insert fracture Suitable for high efficiency machining

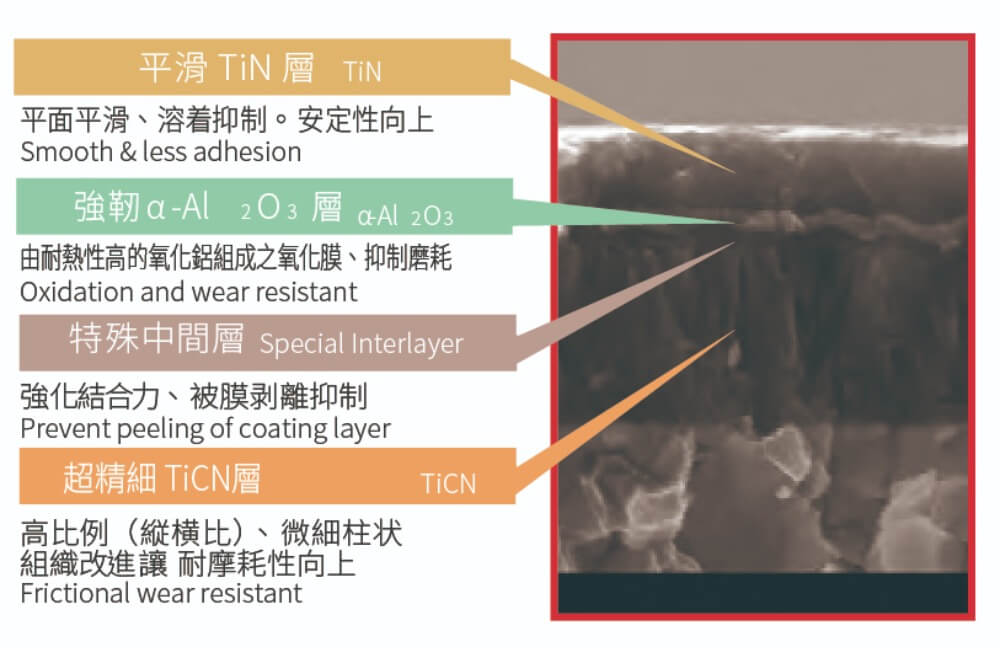

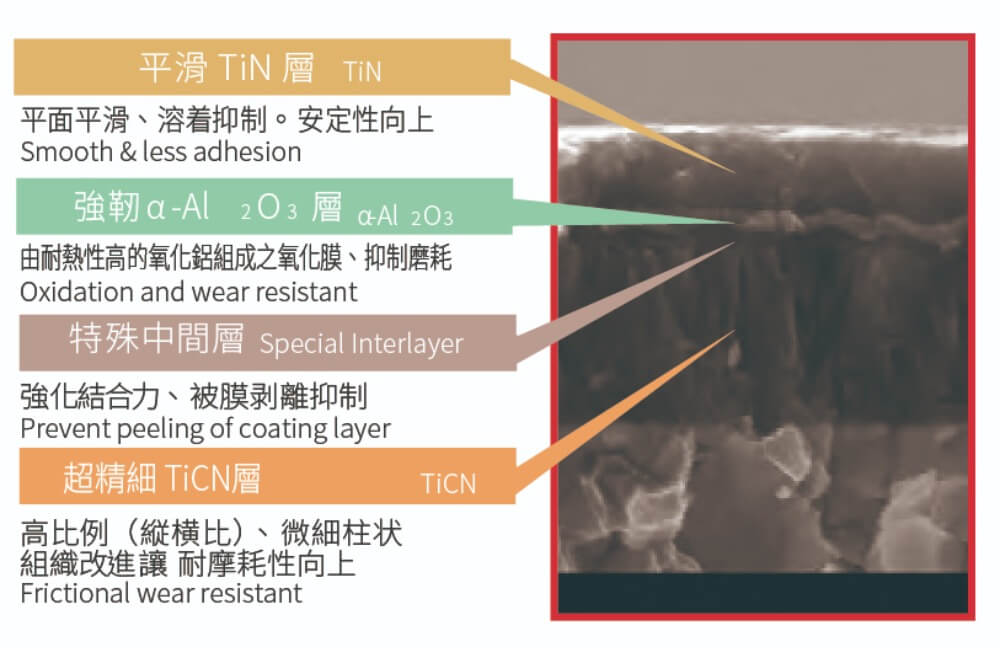

Ni基耐熱合金、馬氏體不鏽鋼用

CVD高耐熱性、耐摩耗性發揮

薄膜塗層技術使安定性向上

For Ni-base heat resistant alloy and martensitic stainless steel High heat resistance and wear resistance with CVD coating Improved stability due to thin film coating technolog

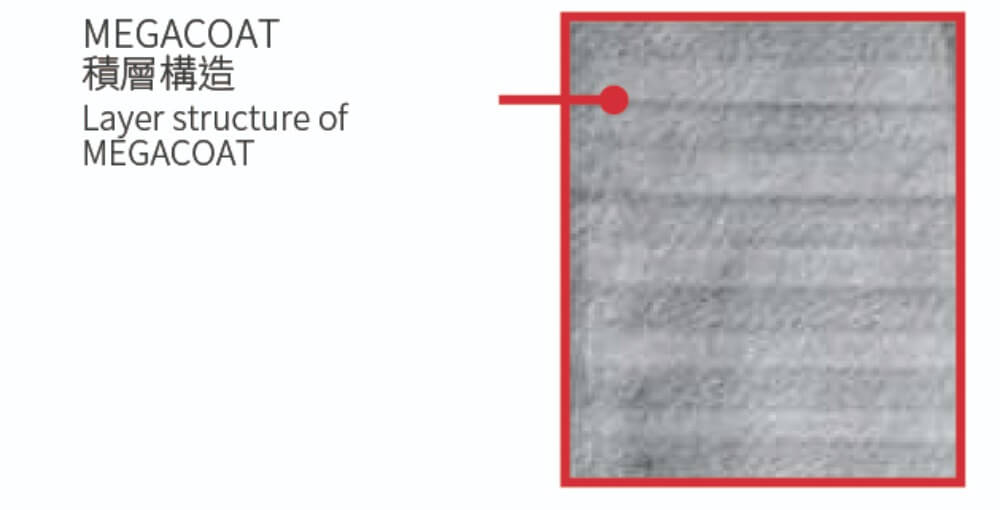

鈦合金、析出硬化型不鏽鋼用

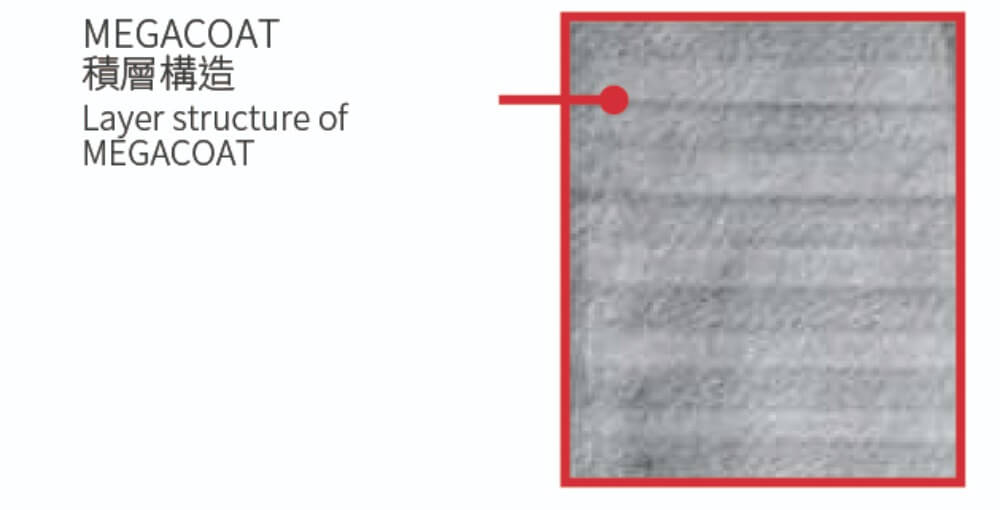

MEGACOAT 積層構造

特殊塗層技術「MEGACOAT NANO」

銑削加工安定化及長壽命的實現

For titanium alloy and precipitation hardened stainless steel

Stabilized milling operation and long tool life by special nano coating layer MEGACOAT NANO

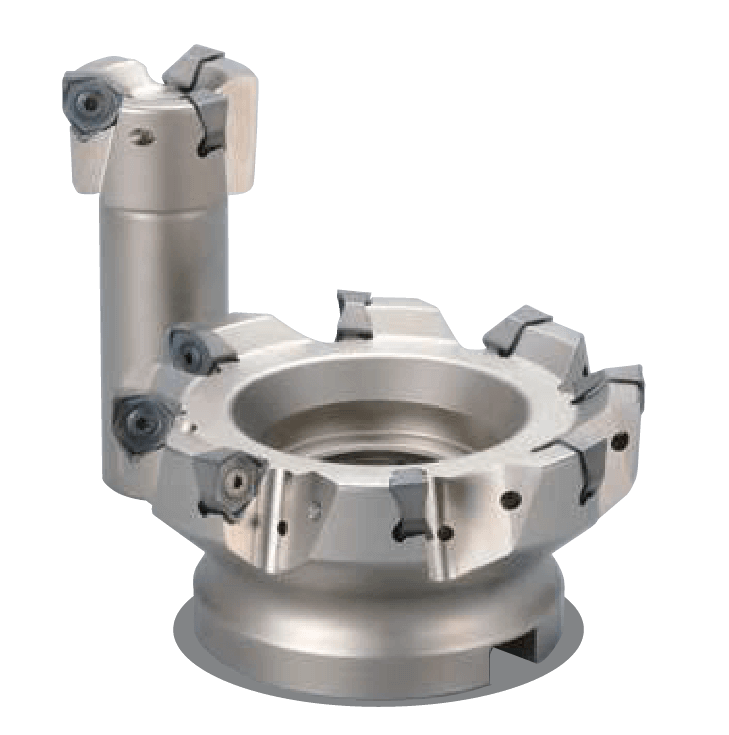

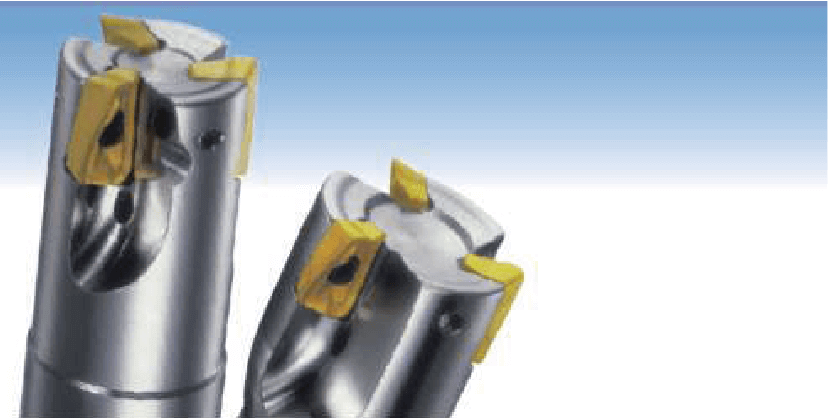

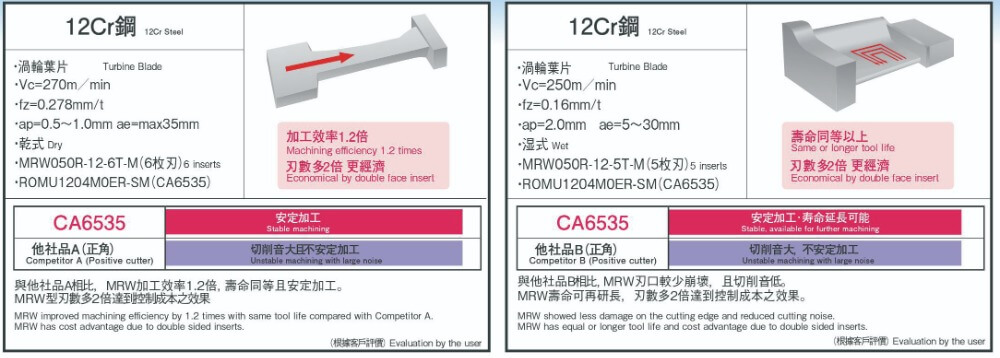

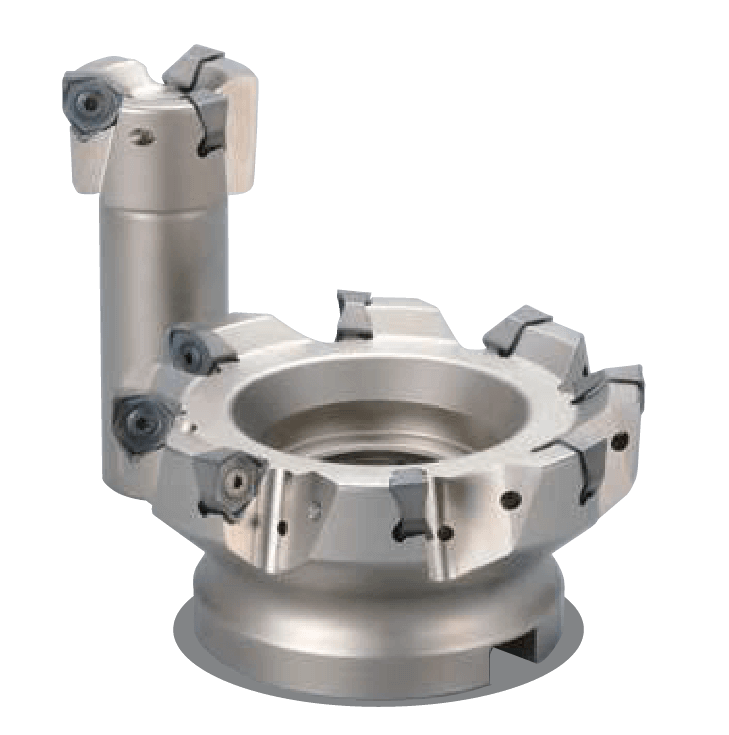

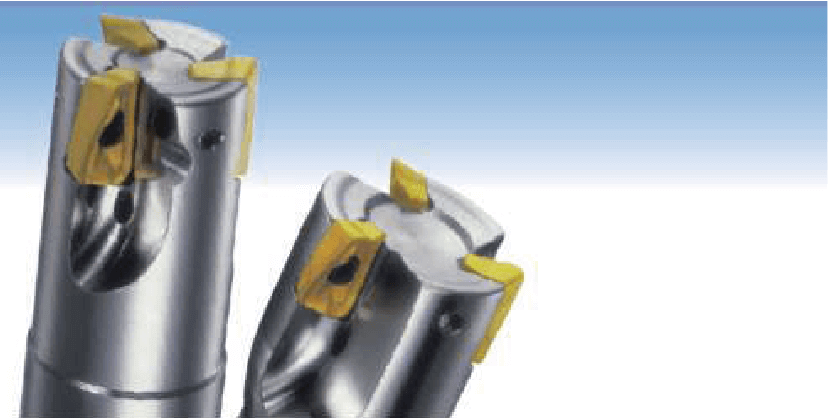

MRW型

高效率 圓形負角銑刀盤

High Efficiency Radius Cutter with Multiple-edge

MRW型

1.両面8角仕様 經濟型

Economical 8-edge insert

2.低抵抗螺旋切削刃。鈍角刃口增強刃口之強度

Low cutting force by helical cutting edge. Obtuse edge increases cutting edge toughness.

3.平鎖結構確保刀片固定,抑制刀片不穩定的情況,實現安定加工

Flat Lock structure realizes stable machining by preventing insert rotation during machining.

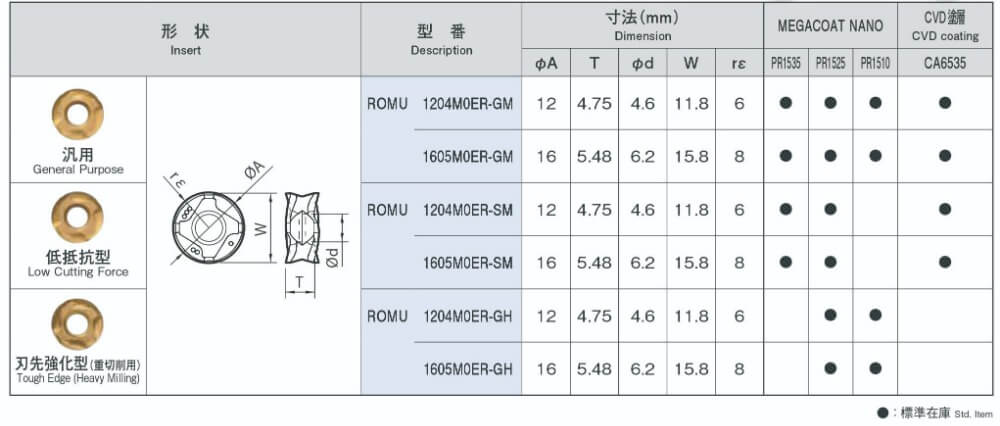

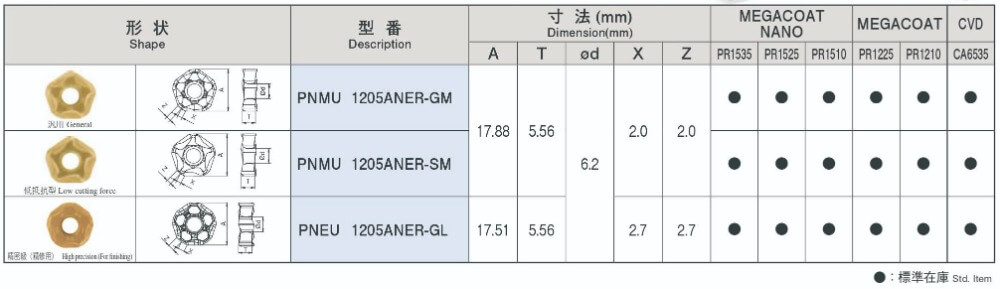

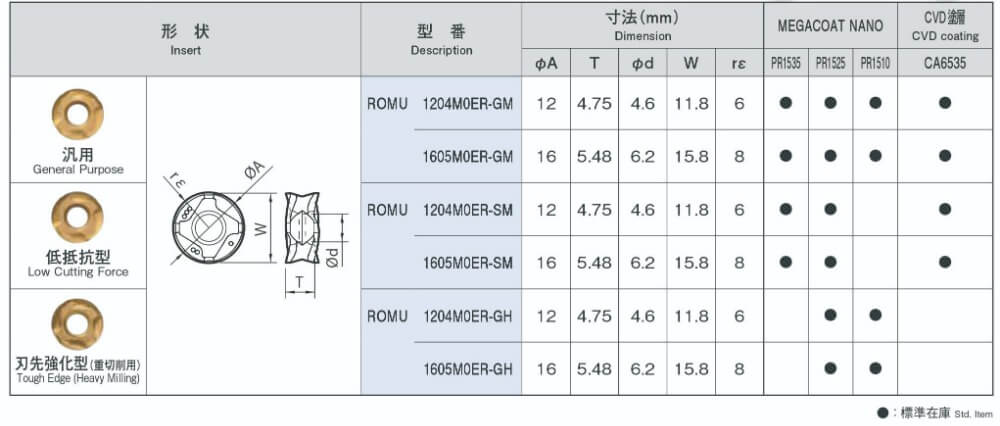

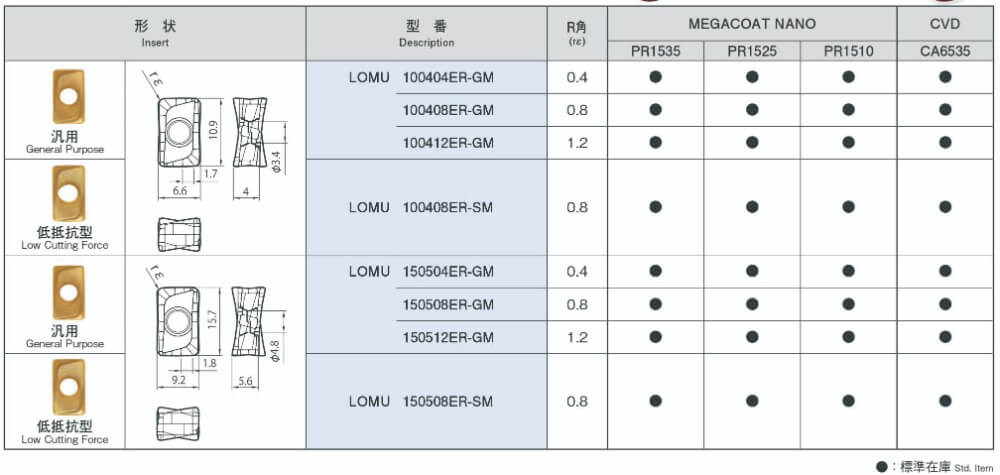

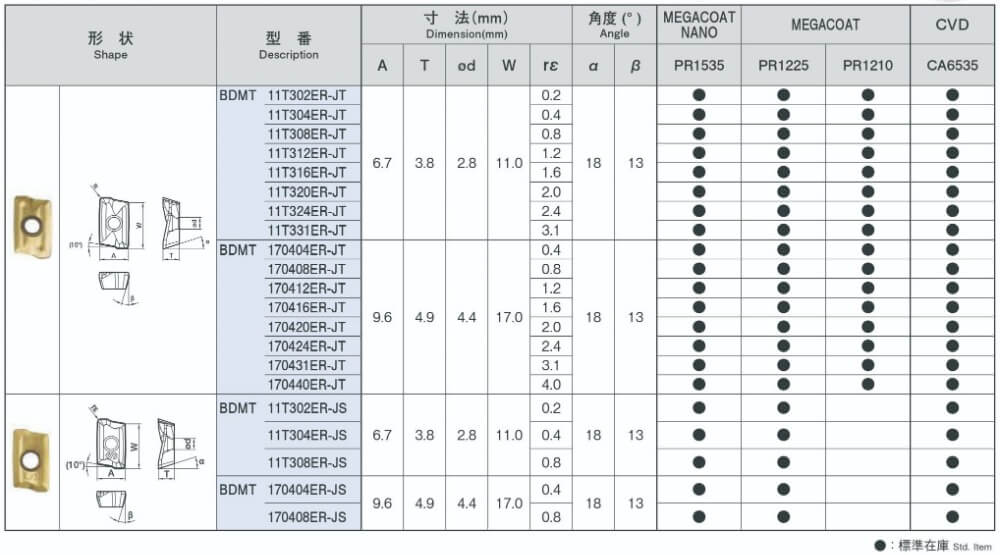

適合刀片 Applicable Insert

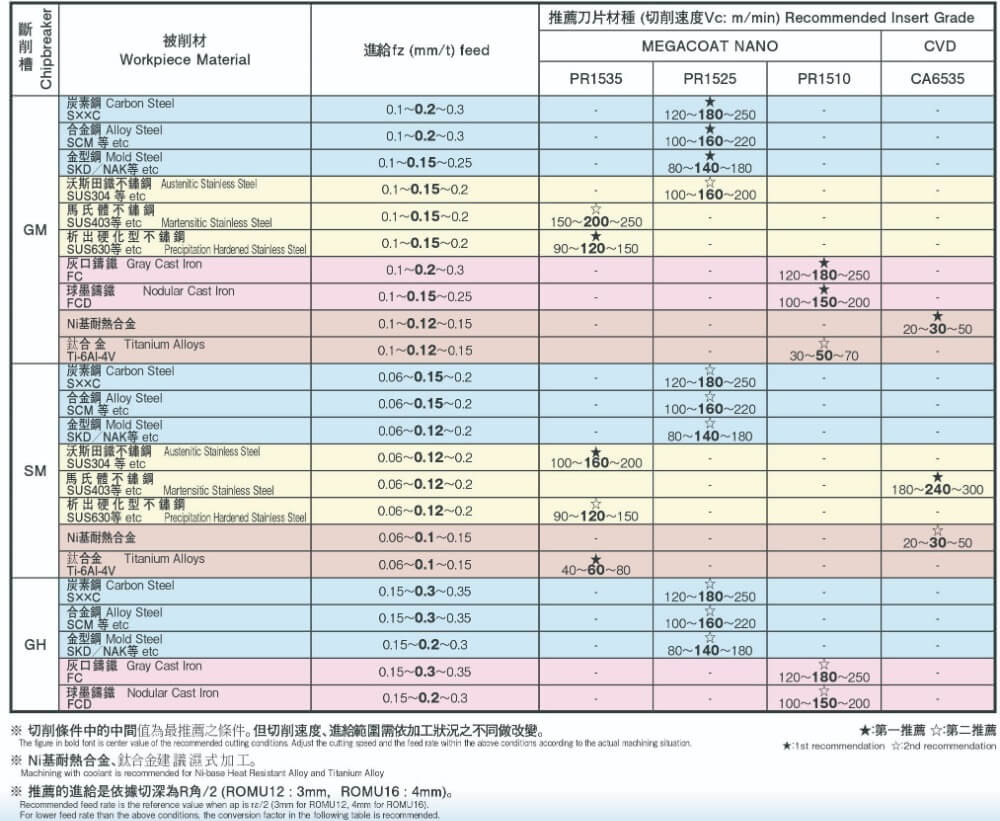

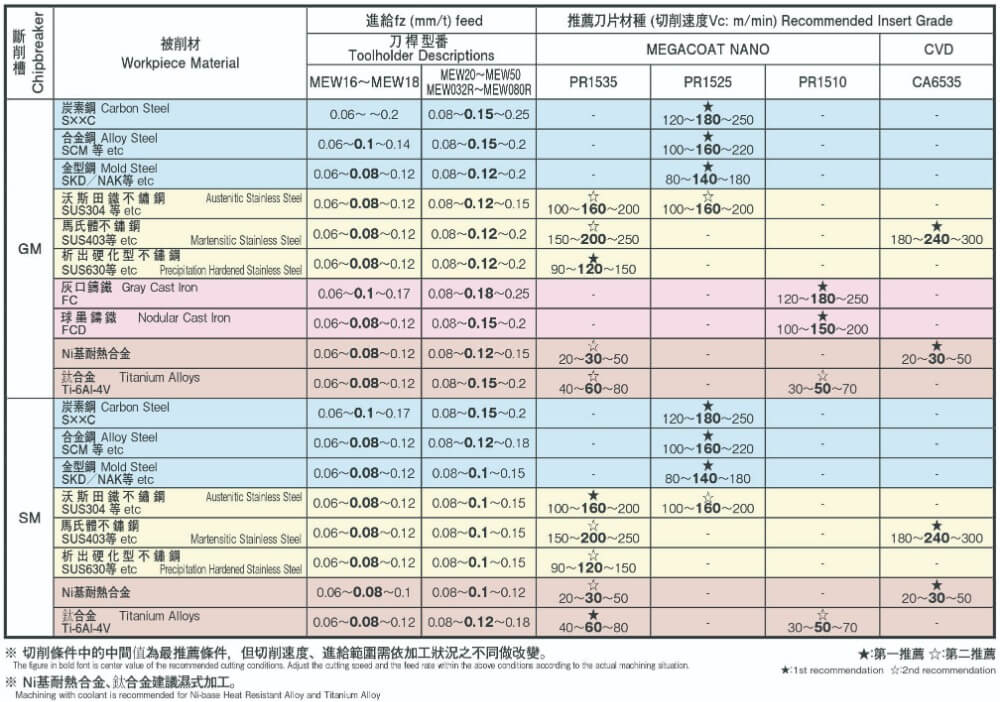

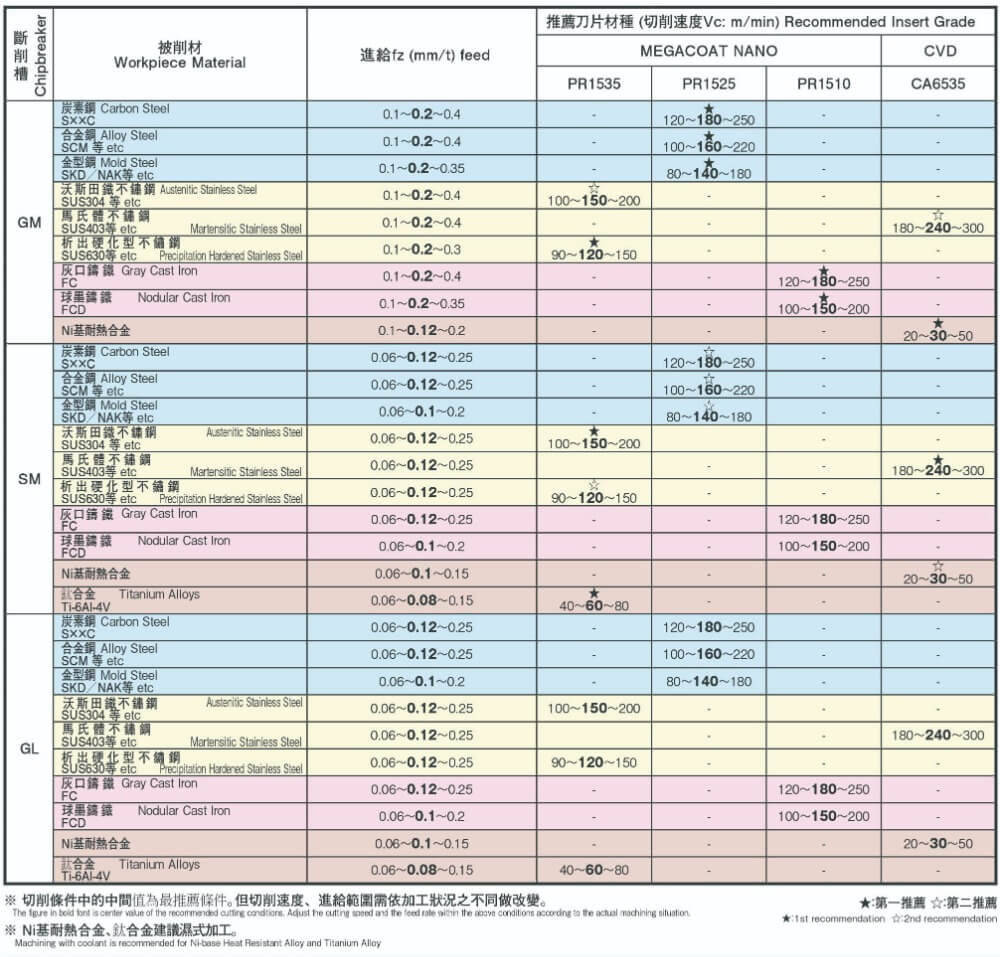

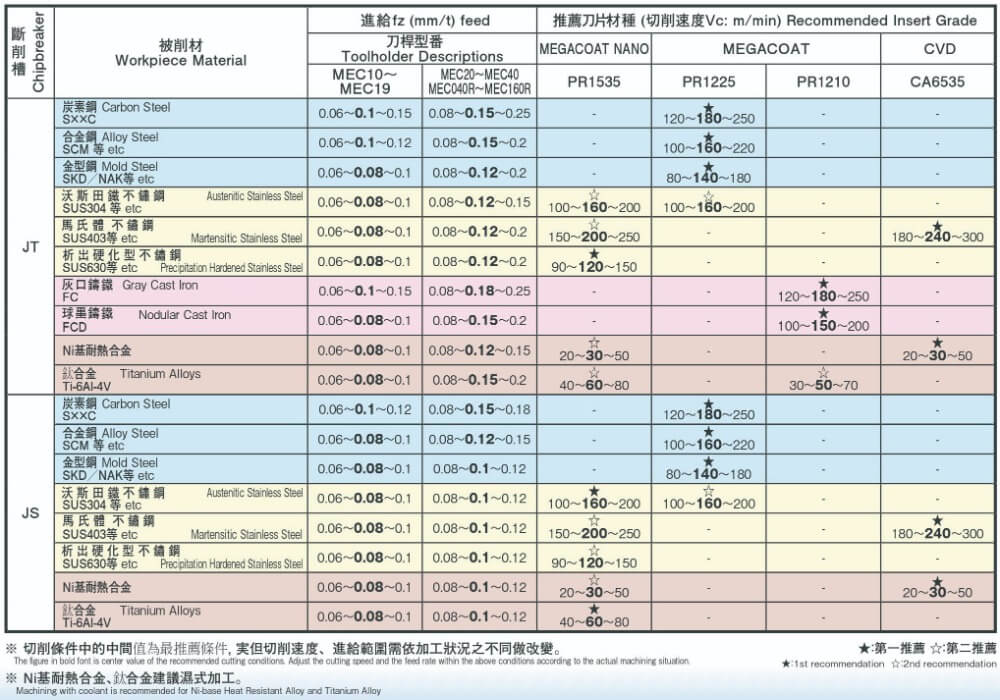

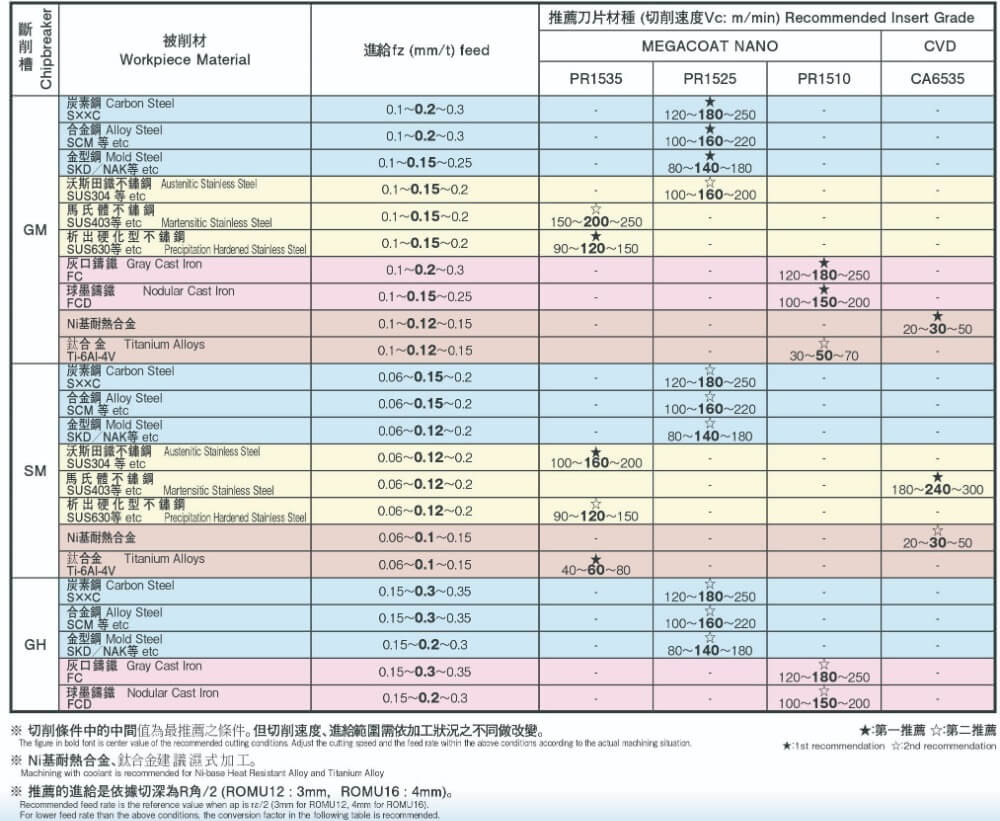

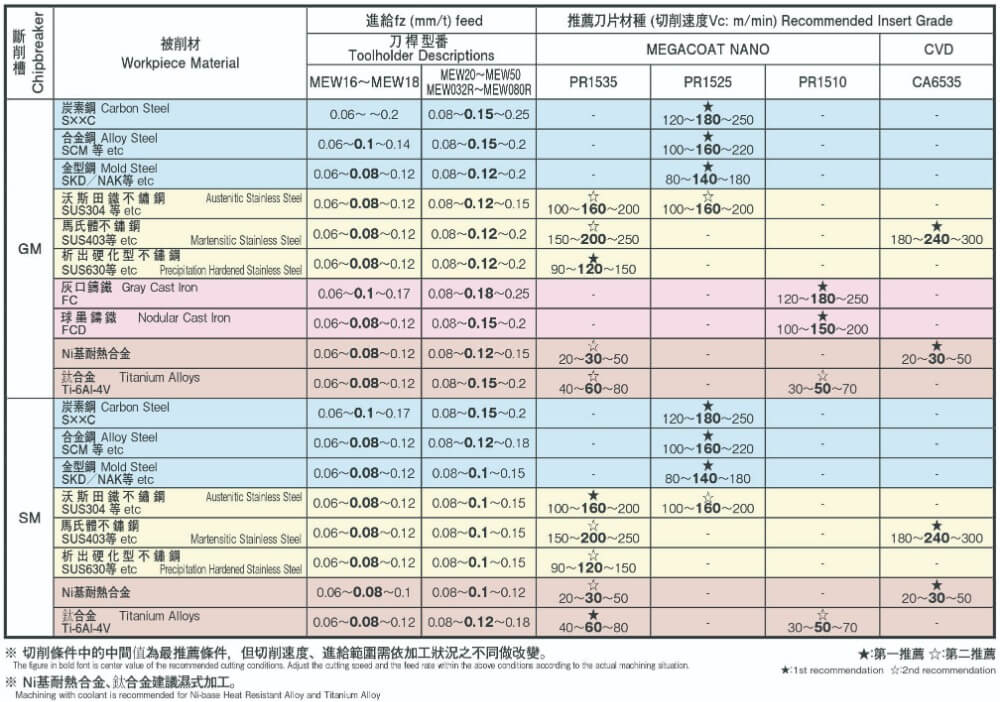

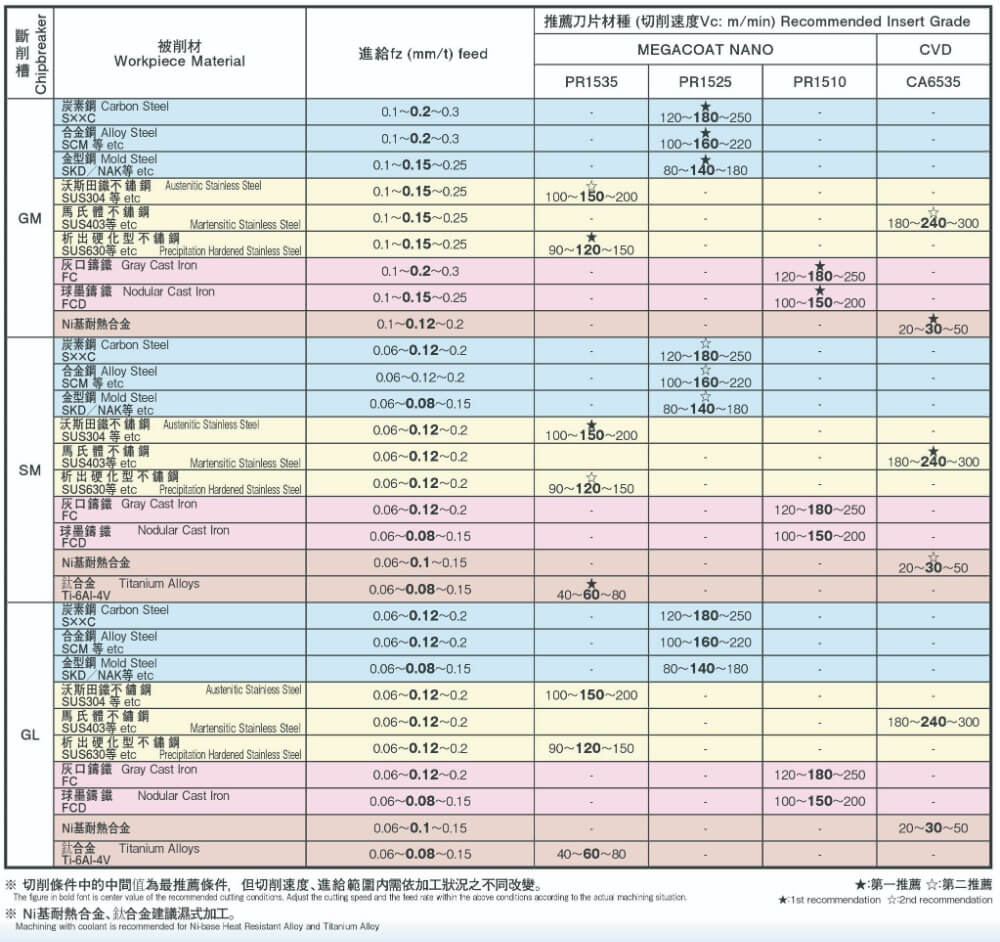

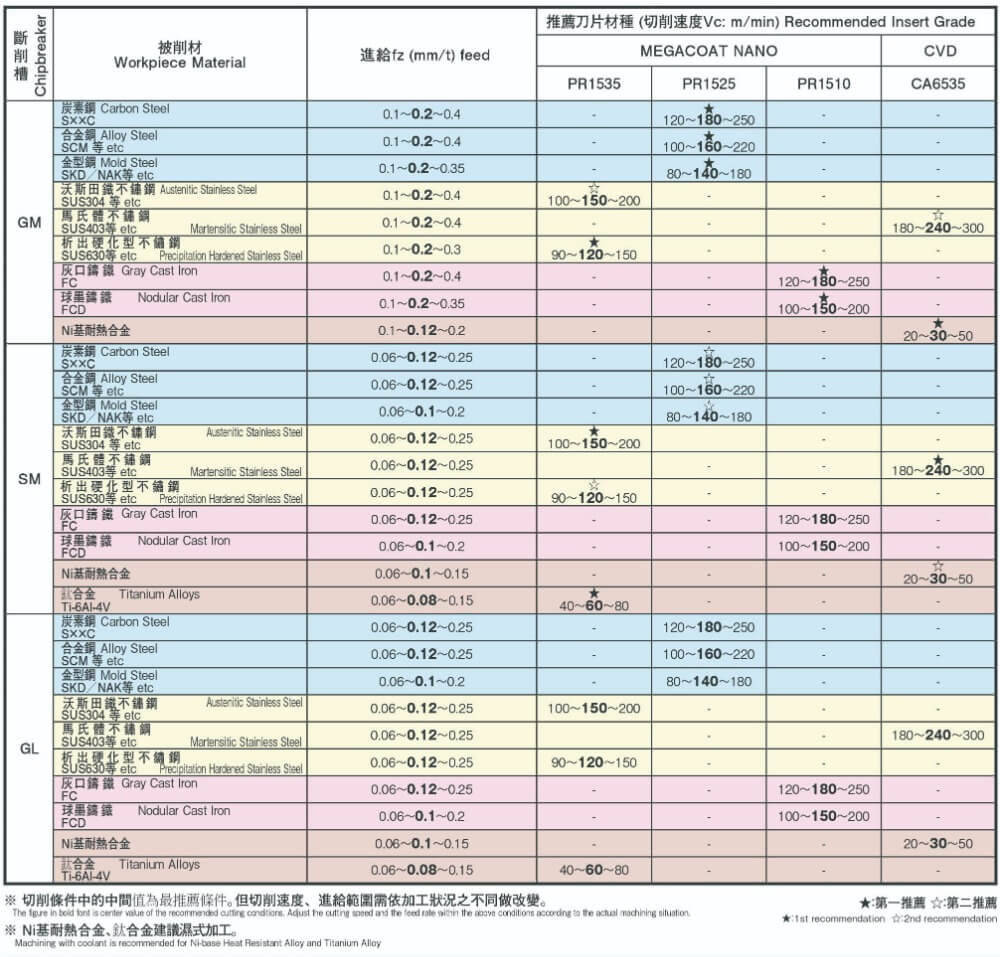

推薦切削條件 Recommended Cutting Conditions

MEW型

兩面4刃仕様 新世代立銑刀

New Generation Endmill with Double Sided 4-edge Use

MEW型

Kyocera’s unique mold technology reduces cutting force equivalent to positive inserts

2.兩面4角仕様,更為經濟

3.增強刀具耐久性和刀片安裝精度

Improved Toolholder Durability and Insert Installation Accuracy

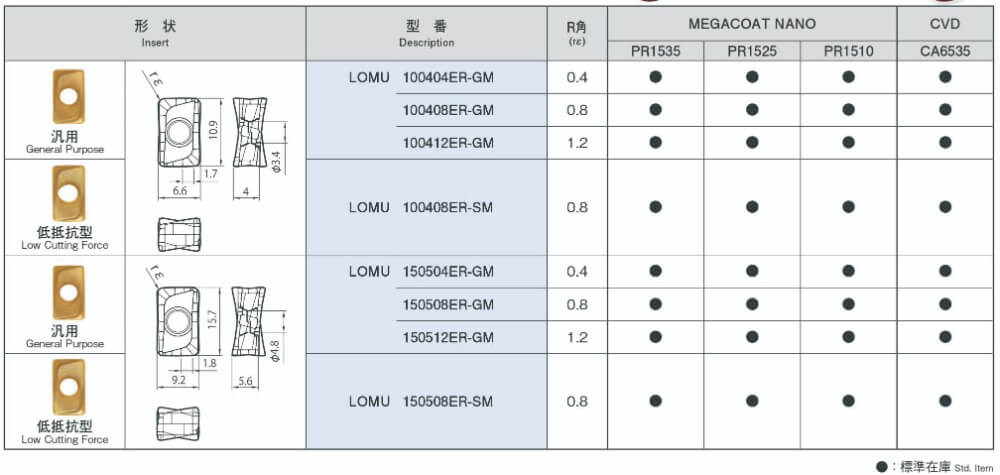

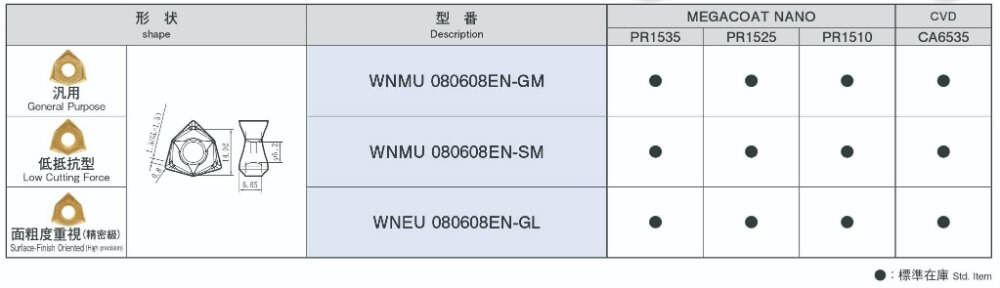

適合刀片 Applicable Insert

推薦切削條件 Recommended Cutting Conditions

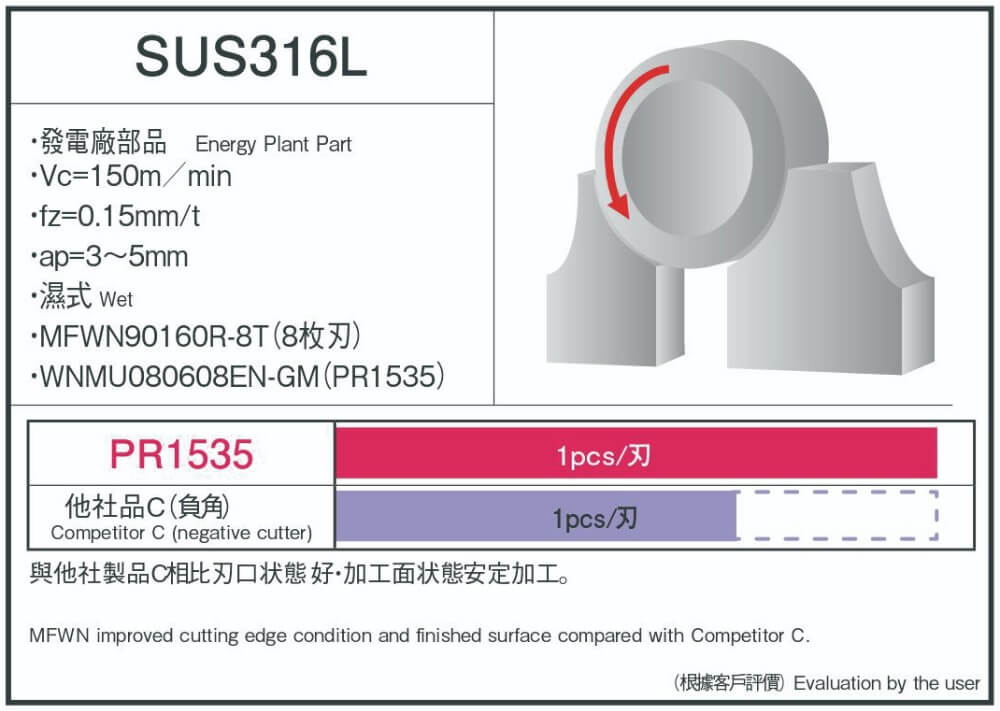

MFWN型

兩面6角仕様 低抵抗90°刀盤

Low Cutting Force 90°Cutter with Double Sided 6-edge Use

MFWN型

1.兩面6角仕様,更經濟。肉厚設計使刀刃更強壯

Economical 6-edge insert and strong thick edge

Low cutting force and less chattering

3.刀盤適用左手刀片(特注品)

Available for left-hand toolholder (custom order) by neutral type inser

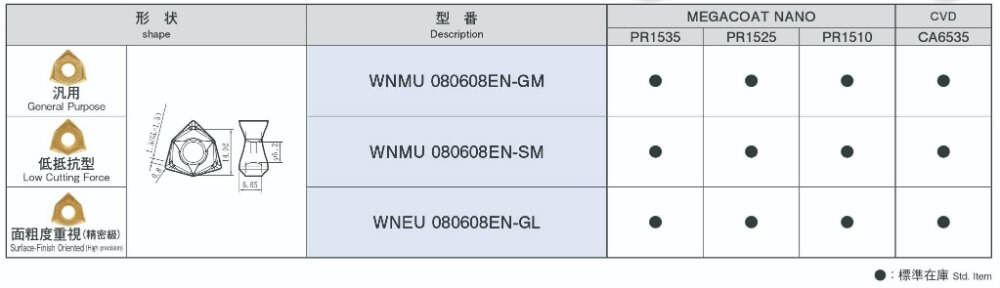

適合刀片 Applicable Insert

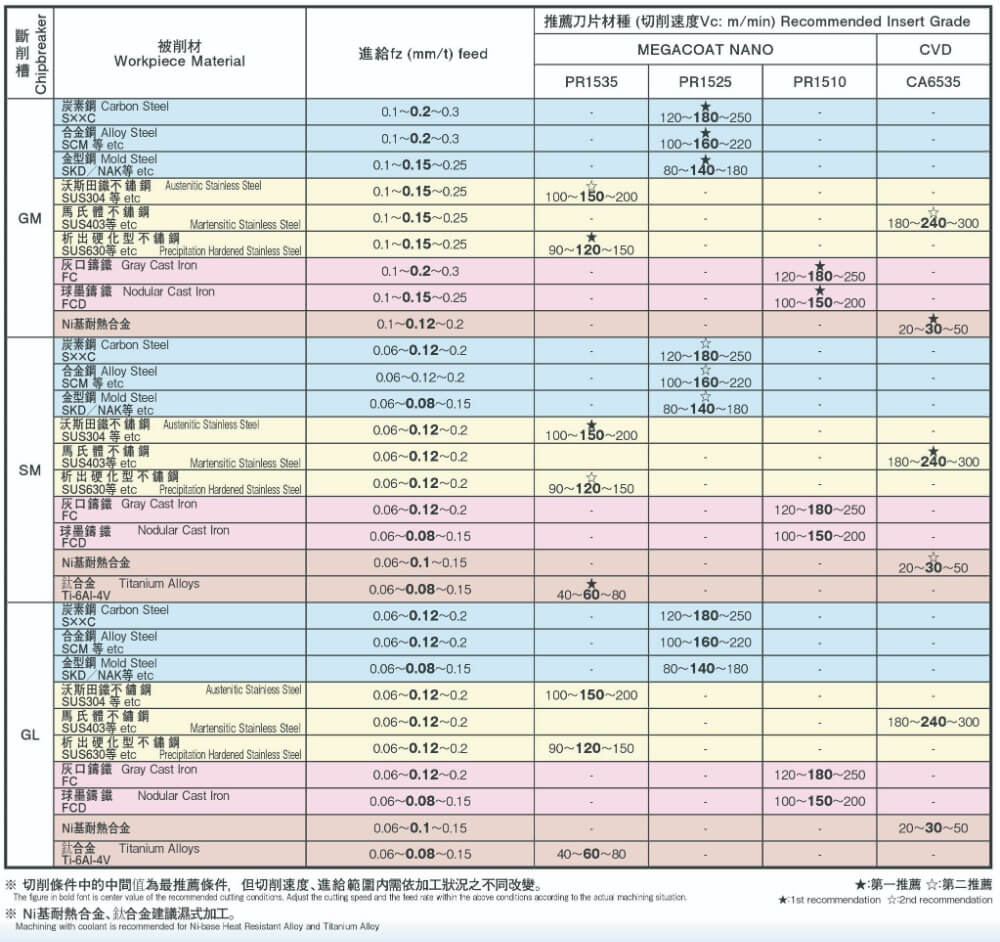

推薦切削條件 Recommended Cutting Conditions

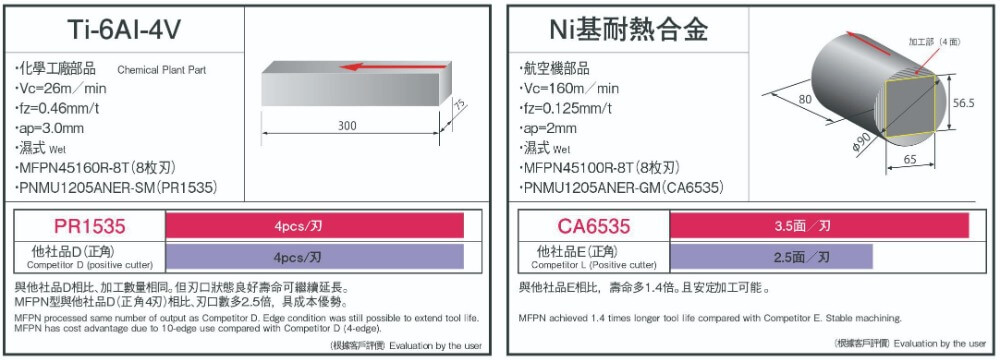

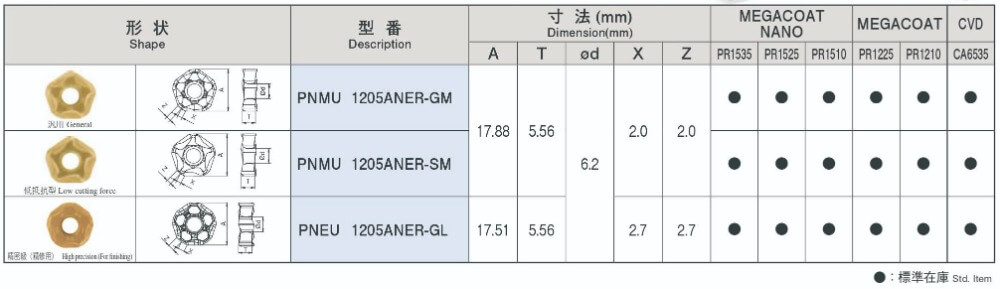

MFPN型

高能率面銑刀

High Efficiency Face Mill

1. 5角形/10刃粗加工・汎用面銑刀

Roughing and general-purpose facemill with 10-edge pentagonal inserts

2. 螺旋切刃構造,低抵抗

Low cutting force due to helical cutting-edge design

3. 負角構造制刀片崩損

Fractures suppressed by double-edge structure

適合刀片 Applicable Insert

推薦切削條件 Recommended Cutting Conditions

推薦切削條件 Recommended Cutting Conditions

MEC型

螺旋立銑刀

MEC型

1.低抵抗、良好的切刃

Low cutting force and sharp cutting performance

2.良好的直角加工、平滑加工壁面

Perfect 90°shoulders, and smooth surface of shoulder wall

3.鋼・不 鏽 鋼・鋳鉄・鋁等、廣泛刀片材質對應各種材種之加工

An extensive grade lineup applicable to a wide range of workpiece materials,

such as steel, stainless steel, cast iron and aluminum.

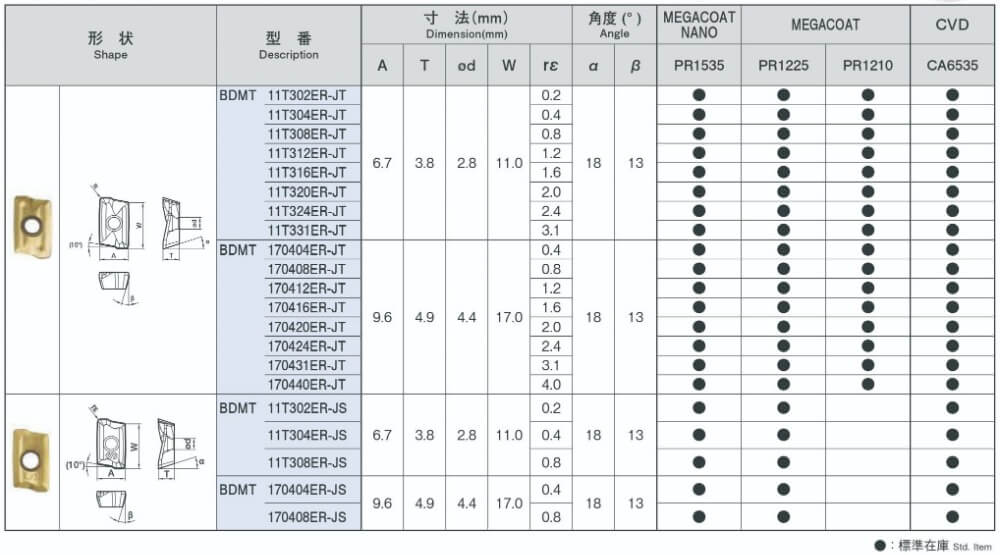

適合刀片 Applicable Insert

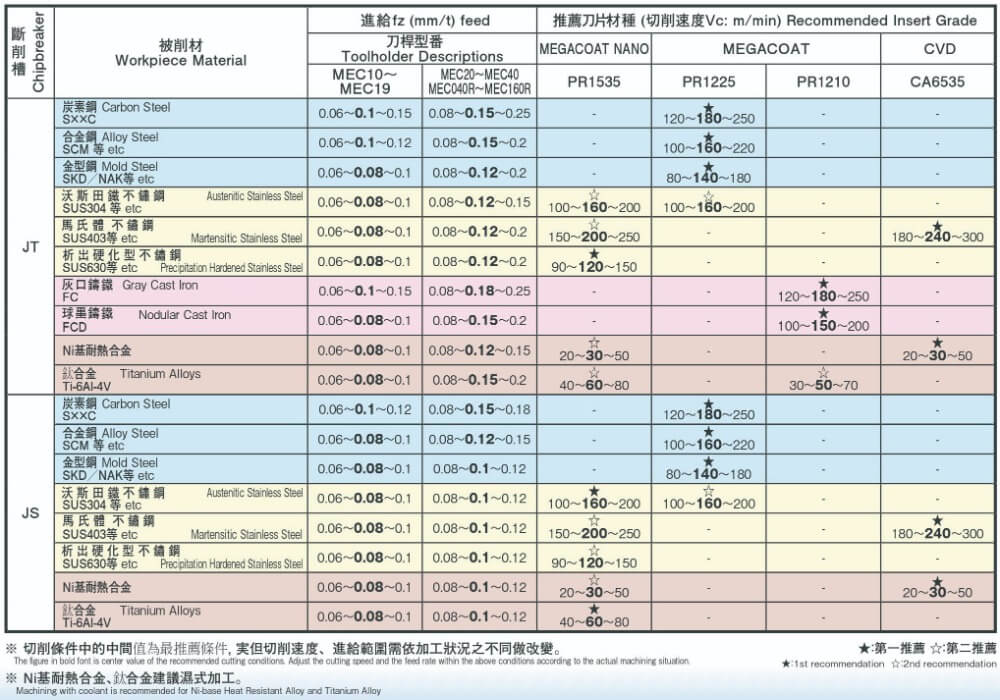

推薦切削條件 Recommended Cutting Conditions